- Copper manifold with holes. Nope.

- Stainless steel mesh topedo, DIY. Nope! got blocked super quick with crud.

- Nylon bags off ebay - yep but you need lots of them and they are a bugger to clean out!

Resorted to pouring out through a sieve that got clogged up last week!

High hopes for this from Maltmiller http://www.themaltmiller.co.uk/index.ph ... ductId=789, arrived yesterday so here is my review.

It's basically a big coil, like a ss slinky under tension.

Connected it up to my boiler, nice easy fitting. I didn't have the exact connect so used a isolator connection (more on that later!)

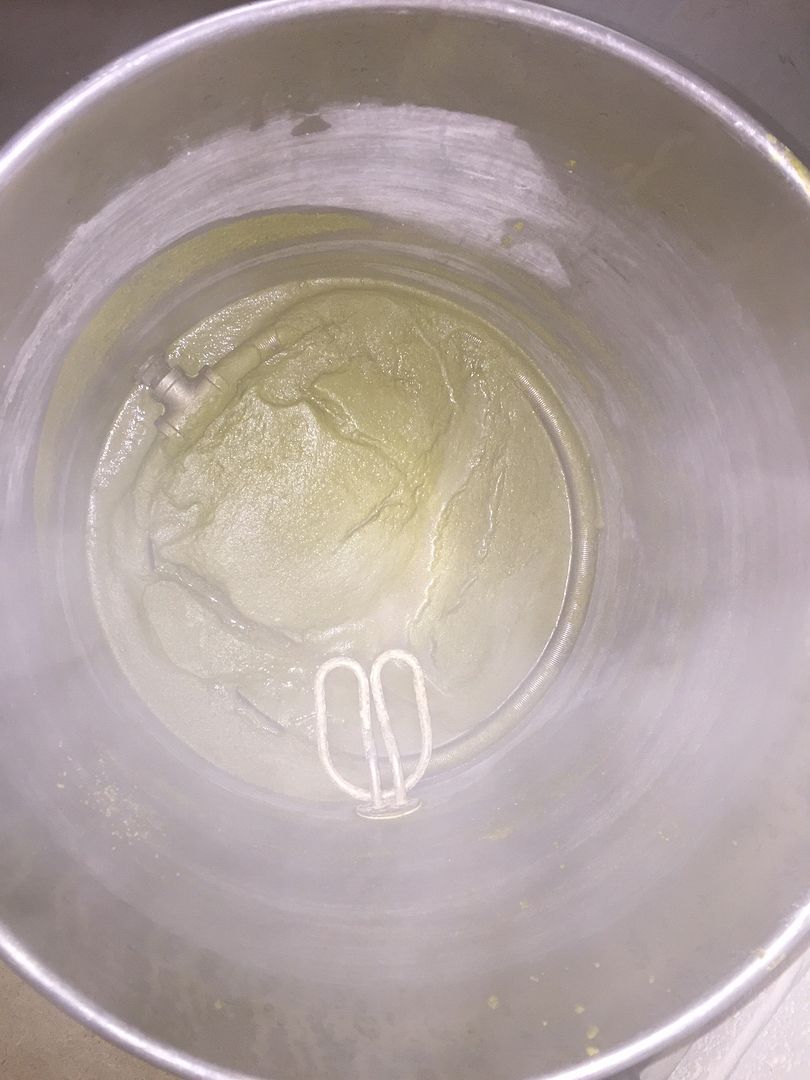

Brewed as normal, Tribute clone so not super hoppy. 300g of pellet hops in 100lt of 1060 wort. Not testing it too much on the first go. Cooled for 30mins using IC.

Result? (See page 5 for Review part II)

An absolute disaster!! From the moment we turned the tap on we never got more than a tiny trickle as you can see in the pics.

We tried :

Scraping it with a paddle

Moving it around with a paddle

Pausing for 5mins before restarting

Blowing air back through to clear in case of a blockage

Not at any moment even for a second did it do more than just a trickle.

Thoughts:

1)Does it need to sit a couple of cms above the base?

2) did the connector reduce the output? (It would still have to pass through one the other side of the pot)

3) we were stiring whilst it cooled, but thats neccesary for the IC to work, plus all the crud was clearly at the bottom by then

I'm going to try again in 2 weeks without an isolator connect. If it's no better then it's going back to maltmiller.

Thoughts, ideas pointing out what I'm doing wrong v welcome!! (Yes the connector is fully open!