So we have all the hardware, now we need the dreaded C code. Many people get frighted when they see a few hundred lines of code, but like most things take it a step at a time any you will soon have it sorted. Feel free to change, edit, publish, etc. I still have a long list of features I want to add, for example when the HLT starts I would to see the estimated time it will hit the target strike temperature.

I'd be interested in other features you think would be useful - I'll take some more screen photos when I do the next brew.

Code: Select all

//BeerComputer v2.0

//Howard Benn Apr 2010

//A super low cost controller for making all grain (AG) beer

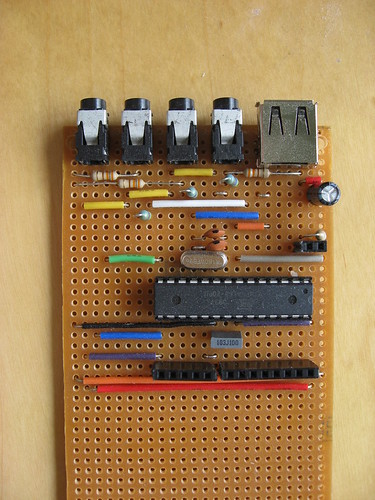

//It uses 3 x Maxim single wire temperature probes - HLT, Mash tun, Kettle

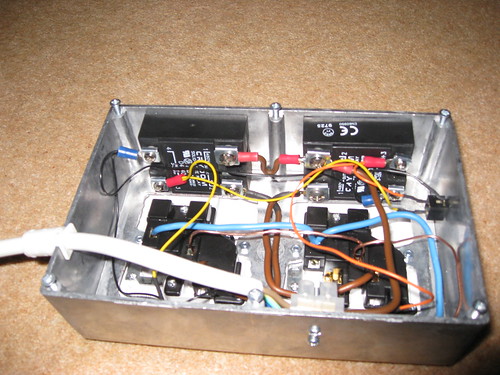

//and the super low cost solid state relays (SSR) now available from China on eBay

//also uses a 4 line x 20 char display again low cost from China from eBay

//fits in a ATMEGA168 to save a few quid hence all the PROGMEM stuff

//include librarys

#include <MsTimer2.h> //used for the 1 second update loop

#include <LiquidCrystal.h> //used to control the LCD display - has to be Arduino 0017 or above to work properly

#include <Bounce.h> //debouncer for the switches

#include <avr/pgmspace.h> //need to store screen in PROGMEM

//define IO pins

#define RS_pin 14 //display - setup to make connection the easy

#define E_pin 15

#define D4_pin 16

#define D5_pin 17

#define D6_pin 18

#define D7_pin 19

#define button_1_pin 11 //buttons with pull-down resistors i.e off=0

#define button_2_pin 10

#define button_3_pin 12

#define heat_pin 8 // IO pins for heater and fridge

#define cool_pin 9

#define HLT_pin 8 // IO pin for HLT - same SSR as heat_pin

#define boil_pin 9 // IO pin for Boiler - same SSR as cool_pin

#define one_wire1_pin 2 //one wire interface to temperature sensors

#define one_wire2_pin 3 //one wire interface to temperature sensors

#define one_wire3_pin 4 //one wire interface to temperature sensors

// Sensor validation

#define INVALIDCRC 1

#define INVALIDMODEL 2

#define NODEVICE 3

#define SLAVEGOOD 0

//Global variables

// setup the LCD with the numbers of the interface pins

LiquidCrystal lcd(RS_pin, E_pin, D4_pin, D5_pin, D6_pin, D7_pin);

//setup the buttons

Bounce button_1 = Bounce(button_1_pin, 5);

Bounce button_2 = Bounce(button_2_pin, 5);

Bounce button_3 = Bounce(button_3_pin, 5);

//set up varable to store temp reading

// 64bit address of device

uint8_t TempAddr[8]; //address of sensor

float HLT_fridge_temp = 0; //temperature sensor 0

float mash_temp = 0; //mash tum

float boiler_temp = 0; //boiler temp

//static variables for FERM

int TargetTemp = 21; //target brewing temp for 4 - 6 day brew

#define HistTime 60000 //time in milli-seconds not to change state of the cool, warm status

long timeChanged = 0; //used to record the last time the temp went outside the +- 0.5 oC margin

long StartTime = 0; // time in millis that we start

float BrewMax = 0; // max temp during fermentation

float BrewMin = 100; // min temp during fermentation

byte cool; //true if fridge is on

byte heat; //true if heater on

//static variables for BREW

float HLTtarget = 80; //target temperature for HLT

byte HLTready = 0; //flag to change from heating to maintaining HLT temp

boolean HLToff = true; //flag to manually turn HLT off

long StartHLT = 0; //HLT on start time

long StartMash = 0; //Mash start time

long StartBoil = 0; //Boil start time

float BoilTarget = 98; //boil target to start boil time

boolean BoilOff = true; //flag to manually turn Boiler off

int BoilTime = 90; //Boil time in minutes

long StartCool = 0;

//Menu control

#define FERM 1

#define BREW 2

byte mode = 0;

byte menu = 1; //position on the menu list

/******************************

Due to the limited RAM we have to store the screen data in PROGMEM

******************************/

// 12345678901234567890

const prog_uchar string_0[] PROGMEM = "Welcome to Howard's"; // "String 0" etc are strings to store in Progmem to get over limited RAM

const prog_uchar string_1[] PROGMEM = " Big Beer Making";

const prog_uchar string_2[] PROGMEM = " Machine";

const prog_uchar string_3[] PROGMEM = "FERM TEST BREW";

// 12345678901234567890

const prog_uchar string_10[] PROGMEM = "Change Target Temp";

const prog_uchar string_11[] PROGMEM = "Current target ";

const prog_uchar string_12[] PROGMEM = "New target ";

const prog_uchar string_13[] PROGMEM = "UP SET DOWN";

// 12345678901234567890

const prog_uchar string_20[] PROGMEM = "Not connected";

const prog_uchar string_21[] PROGMEM = " ";

const prog_uchar string_23[] PROGMEM = "BACK HLT BOILER";

// 12345678901234567890

const prog_uchar string_30[] PROGMEM = "Duration ";

const prog_uchar string_31[] PROGMEM = " Fridge on";

const prog_uchar string_32[] PROGMEM = " Heat on ";

const prog_uchar string_33[] PROGMEM = " ";

const prog_uchar string_34[] PROGMEM = "Min ";

const prog_uchar string_35[] PROGMEM = " Max ";

const prog_uchar string_36[] PROGMEM = "TARGET RESET";

// 12345678901234567890

const prog_uchar string_40[] PROGMEM = "Ready to heat HLT";

const prog_uchar string_41[] PROGMEM = "Water in ?";

const prog_uchar string_42[] PROGMEM = "HLT target ";

const prog_uchar string_43[] PROGMEM = " CHANGE HEAT";

// 12345678901234567890

const prog_uchar string_50[] PROGMEM = "Heating HLT";

const prog_uchar string_51[] PROGMEM = "HLT ready ";

const prog_uchar string_52[] PROGMEM = "Temp ";

const prog_uchar string_53[] PROGMEM = " set ";

const prog_uchar string_54[] PROGMEM = "Time ";

const prog_uchar string_55[] PROGMEM = "BACK OFF MASH";

const prog_uchar string_56[] PROGMEM = "BACK ON MASH";

// 12345678901234567890

const prog_uchar string_60[] PROGMEM = "Mash ";

const prog_uchar string_61[] PROGMEM = "HLT OFF ";

const prog_uchar string_62[] PROGMEM = "HLT ON ";

const prog_uchar string_63[] PROGMEM = "Target ";

const prog_uchar string_64[] PROGMEM = "BACK HLT-OFF BOIL";

const prog_uchar string_65[] PROGMEM = "BACK HLT-ON BOIL";

// 12345678901234567890

const prog_uchar string_70[] PROGMEM = "Heating Boiler";

const prog_uchar string_75[] PROGMEM = "Boil started ";

const prog_uchar string_76[] PROGMEM = "Finish ";

const prog_uchar string_71[] PROGMEM = "Boil Target ";

const prog_uchar string_72[] PROGMEM = "Boil Temp ";

const prog_uchar string_73[] PROGMEM = "BACK OFF BOIL";

const prog_uchar string_74[] PROGMEM = "BACK ON BOIL";

// 12345678901234567890

const prog_uchar string_80[] PROGMEM = "Cool started ";

const prog_uchar string_81[] PROGMEM = "BACK FINISH";

// 12345678901234567890

const prog_uchar string_90[] PROGMEM = "All done";

const prog_uchar string_91[] PROGMEM = "Brew time ";

const prog_uchar string_92[] PROGMEM = "Press any button ";

const prog_uchar string_93[] PROGMEM = "to restart";

/******************************

PRINT FUNCTIONS

*******************************/

void LCDPrintFloat( float f){

if (f>99.9) {

lcd.print ("++.+");

return;

}

if (f<0) {

lcd.print ("--.-");

return;

}

if (f<10) lcd.print (" ");

lcd.print((int)f);

lcd.print(".");

int temp = (f - (int)f) * 10;

lcd.print( abs(temp) );

}

void LCDPrintProgMem (const prog_uchar str[]){

char c;

if(!str) return;

while((c = pgm_read_byte(str++)))

lcd.print(c,BYTE);

}

void LCDPrintTemp (float f){

LCDPrintFloat (f);

lcd.write (0xDF);

lcd.print ("C");

}

void LCDPrintInt (int i){

if (i<10) lcd.print ("0");

lcd.print (i);

}

void LCDClearLine (int line){

lcd.setCursor (0,line);

lcd.print(" ");

}

int ChangeTemp (int current) {

// change the target temperature

//Change Target Temp

//Current target 80oC

//New Target 77oC

//UP SET DOWN

int new_temp = current;

boolean set = false;

lcd.clear ();

while (!set) {

lcd.setCursor(0,0);

LCDPrintProgMem (string_10);

lcd.setCursor(0,1);

LCDPrintProgMem (string_11);

LCDPrintTemp(current);

lcd.setCursor(0,2);

LCDPrintProgMem (string_12);

LCDPrintTemp (new_temp);

lcd.setCursor(0,3);

LCDPrintProgMem (string_13);

//read buttons

if ( button_1.update() ) { //UP button

// Auto increment if the button is held

if ( button_1.read() == HIGH) {

// Make the button retrigger in 500 milliseconds

button_1.rebounce(500);

if (new_temp < 99) new_temp++;

}

}

if ( button_3.update() ) { //DOWN button

// Auto increment if the button is held

if ( button_3.read() == HIGH) {

// Make the button retrigger in 500 milliseconds

button_3.rebounce(500);

if (new_temp > 0) new_temp--;

}

}

if ( button_2.update() ) { //SET button

if ( button_2.read() == HIGH) {

set=true;

}

}

}

lcd.clear ();

return (new_temp);

}

void LCDPrintElapsedTimeDHM (long start) {

int days;

int hours;

int mins;

long TimeNow;

long ElapsedTime;

TimeNow = millis ();

ElapsedTime = TimeNow-start;

days = ElapsedTime/86400000;

hours = (ElapsedTime/3600000) % 24;

mins = (ElapsedTime/60000) % 60;

LCDPrintInt (days);

lcd.print(":");

LCDPrintInt (hours);

lcd.print(":");

LCDPrintInt (mins);

}

void LCDPrintElapsedTimeHMS (long start) {

int hours;

int mins;

int seconds;

long TimeNow;

long ElapsedTime;

TimeNow = millis ();

ElapsedTime = TimeNow-start;

hours = ElapsedTime/3600000;

mins = (ElapsedTime/60000) % 60;

seconds = (ElapsedTime/1000) % 60;

LCDPrintInt(hours);

lcd.print(":");

LCDPrintInt(mins);

lcd.print(":");

LCDPrintInt(seconds);

}

void LCDPrintElapsedTimeMS (long start) {

int mins;

int seconds;

long TimeNow;

long ElapsedTime;

TimeNow = millis ();

ElapsedTime = TimeNow-start;

mins = ElapsedTime/60000;

seconds = (ElapsedTime/1000) % 60;

LCDPrintInt(mins);

lcd.print(":");

LCDPrintInt(seconds);

}

void LCDPrintRemaining (long start, int end) {

int mins;

int seconds;

long TimeNow;

long endMS;

long TimeToGo;

TimeNow = millis ();

endMS = end * 60000; //convert from minutes to mS

TimeToGo = start + endMS - TimeNow;

mins = TimeToGo/60000;

seconds = (TimeToGo/1000) % 60;

LCDPrintInt(mins);

lcd.print(":");

LCDPrintInt(seconds);

}

/******************************

Startup screen and control

*******************************/

void LCDPrintWelcome () {

lcd.clear();

lcd.setCursor(0,0);

LCDPrintProgMem (string_0);

lcd.setCursor(0,1);

LCDPrintProgMem (string_1);

lcd.setCursor(0,2);

LCDPrintProgMem (string_2);

lcd.setCursor(0,3);

LCDPrintProgMem (string_3);

}

void WelcomeButtons (){

while (mode == 0) { //repeat until a button is pressed

if ( button_1.update() ) { //set into FERM mode

if ( button_1.read() == HIGH) {

lcd.clear();

mode = FERM;

StartTime = millis ();

cool = false; //set up fridge startup conditions

heat = false;

}

}

if ( button_2.update() ) { //Test

if ( button_2.read() == HIGH) {

lcd.clear();

Test ();

}

}

if ( button_3.update() ) { //set into BREW mode

if ( button_3.read() == HIGH) {

lcd.clear();

mode = BREW;

}

}

}

}

/******************************

Test Mode

*******************************/

void PrintTest (float temperature){

if (temperature != 0) {

LCDPrintTemp (temperature);

LCDPrintProgMem (string_21);

}

else {

LCDPrintProgMem (string_20);

}

}

void Test () {

boolean button_pushed = false;

lcd.clear();

while (!button_pushed) {

lcd.setCursor(0,0);

PrintTest (HLT_fridge_temp);

lcd.setCursor(0,1);

PrintTest (mash_temp);

lcd.setCursor(0,2);

PrintTest (boiler_temp);

lcd.setCursor(0,3);

LCDPrintProgMem (string_23);

if ( button_1.update() ) { //back to start

if ( button_1.read() == HIGH) {

LCDPrintWelcome();

button_pushed = true;

}

}

if ( button_2.update() ) { //HLT on/off

if ( button_2.read() == HIGH) {

if (!HLToff) {

HLToff = true;

digitalWrite (HLT_pin, LOW);

digitalWrite (boil_pin, LOW);

}

else {

HLToff = false;

digitalWrite (HLT_pin, HIGH);

digitalWrite (boil_pin, LOW);

}

}

}

if ( button_3.update() ) { //boiler on/off

if ( button_3.read() == HIGH) {

if (!BoilOff) {

BoilOff = true;

digitalWrite (HLT_pin, LOW);

digitalWrite (boil_pin, LOW);

}

else {

BoilOff = false;

digitalWrite (HLT_pin, LOW);

digitalWrite (boil_pin, HIGH);

}

}

}

}

}

/******************************

Fermentation control

*******************************/

void LCDPrintFerm () {

/* Calculate elapsed time and temperature, print results

Duration 12:10:30

20.1 oC Heat

Min 19.5 Max 22.2

CHANGE FERM TEMP

*/

if (HLT_fridge_temp > BrewMax) BrewMax = HLT_fridge_temp; //set max

if (HLT_fridge_temp < BrewMin) BrewMin = HLT_fridge_temp; //set min

lcd.setCursor(0,0);

LCDPrintProgMem (string_30);

LCDPrintElapsedTimeDHM (StartTime);

lcd.setCursor(0,1);

LCDPrintTemp (HLT_fridge_temp);

if (cool) LCDPrintProgMem (string_31);

if (heat) LCDPrintProgMem (string_32);

if (!cool & !heat) LCDPrintProgMem (string_33);

lcd.setCursor(0,2);

LCDPrintProgMem (string_34);

LCDPrintFloat (BrewMin);

LCDPrintProgMem (string_35);

LCDPrintTemp (BrewMax);

lcd.setCursor(0,3);

LCDPrintProgMem (string_36);

if ( button_1.update() ) { //change button

if ( button_1.read() == HIGH) {

TargetTemp = ChangeTemp (TargetTemp);

}

}

if ( button_3.update() ) { //reset max and min

if ( button_3.read() == HIGH) {

BrewMax = HLT_fridge_temp;

BrewMin = HLT_fridge_temp;

}

}

}

void ControlTemp (){

//Controls the Fridge internal temperature - uses a 0.5 degree historysis and a programmable delay

//to prevent the fridge going on and off too often

//Thought about using the PID lib, but a bit over the top for this

long timeNow;

timeNow = millis();

if ((timeNow - timeChanged) < HistTime) return; // don't do anything if there has been a recent change

//check if we need to turn the fridge on

if (HLT_fridge_temp > (TargetTemp + 0.5)) {

if (cool == false) {

timeChanged = millis(); //if we change state note time

cool = true;

digitalWrite(cool_pin, HIGH); //fridge relay on

}

}

else {

if (cool == true) {

timeChanged = millis();

cool = false;

digitalWrite(cool_pin, LOW); //fridge relay off

}

}

// check if we need to turn the heater on

if (HLT_fridge_temp < (TargetTemp - 0.5)) {

if (heat == false){

timeChanged = millis();

heat = true;

digitalWrite(heat_pin, HIGH); //heat relay on

}

}

else {

if (heat == true) {

timeChanged = millis();

heat = false;

digitalWrite(heat_pin, LOW); //heat relay off

}

}

}

/******************************

Brew mode

*******************************/

void MenuUpDown () {

if ( button_1.update() ) { //Back

if ( button_1.read() == HIGH) {

if (menu > 1) menu--;

lcd.clear();

}

}

if ( button_3.update() ) { //Forward

if ( button_3.read() == HIGH) {

menu++;

lcd.clear();

}

}

}

void HLTcontrol () {

if (HLToff) { //HLT forced off by MMI

digitalWrite (HLT_pin, LOW);

return;

}

if (HLT_fridge_temp < HLTtarget) {

digitalWrite (boil_pin, LOW); //only ever allow 1 element to be on at a time

digitalWrite (HLT_pin, HIGH);

}

else {

digitalWrite (boil_pin, LOW);

digitalWrite (HLT_pin, LOW);

HLTready = true;

}

}

void LCDStartHLT () {

/* get ready to turn HLT on

Ready to heat HLT

Water in?

Current target 80oC

BACK CHANGE HEAT

*/

lcd.setCursor(0,0);

LCDPrintProgMem (string_40);

lcd.setCursor(0,1);

LCDPrintProgMem (string_41);

lcd.setCursor(0,2);

LCDPrintProgMem (string_42);

LCDPrintTemp(HLTtarget);

lcd.setCursor(0,3);

LCDPrintProgMem (string_43);

MenuUpDown (); //check for menu changes

if ( button_2.update() ) { //change button

if ( button_2.read() == HIGH) {

HLTtarget = ChangeTemp (HLTtarget);

}

}

}

void LCDHeatHLT () {

/* HLT on

Heating HLT

Current 66 target 80

Time 0:20:30

BACK OFF MASH */

if (StartHLT == 0) {

StartHLT = millis(); //set starttime first time around

HLToff = false;

}

lcd.setCursor(0,0);

if (!HLTready){

LCDPrintProgMem (string_50);

}

else {

LCDPrintProgMem (string_51);

}

lcd.setCursor(0,1);

LCDPrintProgMem (string_52);

LCDPrintFloat (HLT_fridge_temp);

LCDPrintProgMem (string_53);

LCDPrintTemp(HLTtarget);

lcd.setCursor(0,2);

LCDPrintProgMem (string_54);

LCDPrintElapsedTimeHMS (StartHLT);

lcd.setCursor(0,3);

if (!HLToff) {

LCDPrintProgMem (string_55);

}

else {

LCDPrintProgMem (string_56);

}

MenuUpDown (); //check for menu changes

if ( button_2.update() ) { //change button

if ( button_2.read() == HIGH) {

if (!HLToff) HLToff = true;

else HLToff = false;

}

}

HLTcontrol ();

}

void LCDMash () { //NEED TO SORT setting target temp ?

/*

Mash 66.3oC 40:53

HLT off 50.4oC

target 80.0oC

BACK HLT_ON BOIL */

if (StartMash == 0) StartMash = millis(); //set starttime first time around

lcd.setCursor(0,0);

LCDPrintProgMem (string_60);

LCDPrintTemp (mash_temp);

lcd.print (" ");

LCDPrintElapsedTimeMS (StartMash);

lcd.setCursor(0,1);

if (HLToff) {

LCDPrintProgMem (string_61);

}

else {

LCDPrintProgMem (string_62);

}

LCDPrintTemp (HLT_fridge_temp);

lcd.setCursor(0,2);

LCDPrintProgMem (string_63);

LCDPrintTemp (HLTtarget);

lcd.setCursor(0,3);

if (!HLToff) {

LCDPrintProgMem (string_64);

}

else {

LCDPrintProgMem (string_65);

}

MenuUpDown (); //check for menu changes

if ( button_2.update() ) { //change button

if ( button_2.read() == HIGH) {

if (!HLToff) {

HLToff = true;

}

else {

HLToff = false;

}

}

}

HLTcontrol ();

}

void LCDHeatBoiler () { //Heat Boiler until we hit target temp then start timer

/*

Heating Boiler

Boil target 98 oC

Boiler 80.2 oC

BACK OFF BOIL

*/

lcd.setCursor(0,0);

LCDPrintProgMem (string_70);

lcd.setCursor(0,1);

LCDPrintProgMem (string_71);

LCDPrintTemp (BoilTarget);

lcd.setCursor(0,2);

LCDPrintProgMem (string_72);

LCDPrintTemp (boiler_temp);

lcd.setCursor(0,3);

if (!BoilOff) {

LCDPrintProgMem (string_73);

digitalWrite (HLT_pin, LOW); //always make sure HLT is iff before we turn the boiler on

digitalWrite (boil_pin, HIGH);

}

else {

LCDPrintProgMem (string_74);

digitalWrite (boil_pin, LOW);

}

MenuUpDown (); //check for menu changes

if ( button_2.update() ) { //change button

if ( button_2.read() == HIGH) {

if (!BoilOff) {

BoilOff = true;

}

else {

BoilOff = false;

}

}

}

}

void LCDBoil () { //Boil and display timer

/*

Boil started 24:30

Finish 63:20

Temp 99 oC

BACK OFF COOL

*/

if (StartBoil == 0) {

StartBoil = millis(); //set starttime first time around

}

lcd.setCursor(0,0);

LCDPrintProgMem (string_75);

LCDPrintElapsedTimeMS (StartBoil);

lcd.setCursor(0,1);

LCDPrintProgMem (string_76);

LCDPrintRemaining (StartBoil, BoilTime);

lcd.setCursor(0,2);

LCDPrintProgMem (string_72);

LCDPrintTemp (boiler_temp);

lcd.setCursor(0,3);

if (!BoilOff) {

LCDPrintProgMem (string_73);

digitalWrite (HLT_pin, LOW); //always make sure HLT is iff before we turn the boiler on

digitalWrite (boil_pin, HIGH);

}

else {

LCDPrintProgMem (string_74);

digitalWrite (boil_pin, LOW);

}

MenuUpDown (); //check for menu changes

if ( button_2.update() ) { //change button

if ( button_2.read() == HIGH) {

if (!BoilOff) {

BoilOff = true;

}

else {

BoilOff = false;

}

}

}

}

void LCDCool () { //Boil and display timer

/*

Cool started 24:30

Temp 99 oC

BACK FINISH

*/

if (StartCool == 0) {

StartCool = millis(); //set starttime first time around

digitalWrite (boil_pin, LOW); // turn element off

}

lcd.setCursor(0,0);

LCDPrintProgMem (string_80);

LCDPrintElapsedTimeMS (StartCool);

lcd.setCursor(0,2);

LCDPrintProgMem (string_52);

LCDPrintTemp (boiler_temp);

lcd.setCursor(0,3);

LCDPrintProgMem (string_81);

MenuUpDown (); //check for menu changes

}

void LCDFinish () {

lcd.setCursor(0,0);

LCDPrintProgMem (string_90);

lcd.setCursor(0,1);

LCDPrintProgMem (string_91);

LCDPrintElapsedTimeHMS (StartHLT);

lcd.setCursor(0,2);

LCDPrintProgMem (string_92);

lcd.setCursor(0,3);

LCDPrintProgMem (string_93);

if ( button_1.update() || button_2.update() || button_3.update() ) { //any button

if ( (button_1.read() || button_2.read() || button_3.read()) == HIGH) {

mode = 0;

}

}

}

/******************************

Setup

*******************************/

void OneSecondLoop() {

//read the existing stored temperature values from RAM

//start the next conversion - takes around 750mS so should be ready next time we get here

//Need to remember and reset the pin to make the test loops work

uint8_t pin;

pin = get_pin();

change_pin (one_wire1_pin); //set to first sensor

HLT_fridge_temp = getTempC(); //temperature sensor 0

globalTempRequest();

change_pin (one_wire2_pin);

mash_temp = getTempC(); //mash tum

globalTempRequest();

change_pin (one_wire3_pin);

boiler_temp = getTempC(); //boiler temp

globalTempRequest();

change_pin (pin);

}

void setup() {

// set up the LCD's number of columns and rows:

lcd.begin(20,4);

//configure pins - inputs are defaulted

pinMode(heat_pin, OUTPUT);

pinMode(cool_pin, OUTPUT);

// turn SSRs off

digitalWrite (heat_pin, LOW);

digitalWrite (cool_pin, LOW);

SetAddress (&TempAddr[0]);

MsTimer2::set(1000, OneSecondLoop); // 1 second loop

MsTimer2::start();

}

void loop() {

switch (mode) {

case 0:

LCDPrintWelcome();

WelcomeButtons ();

break;

case 1:

ControlTemp ();

LCDPrintFerm ();

break;

case 2:

switch (menu){

case 1:

LCDStartHLT ();

break;

case 2:

LCDHeatHLT ();

break;

case 3:

LCDMash ();

break;

case 4:

LCDHeatBoiler ();

break;

case 5:

LCDBoil ();

break;

case 6:

LCDCool ();

break;

case 7:

LCDFinish ();

break;

}

break;

}

}

You will also need the temp sensor code

Code: Select all

//Tiny temp - small version of OneWire and DallasTemperature

//with only one sensor per wire but with hot swap

// This is ripped off from the DallasTemperature library,

// and you can ONLY have a single sensor per wire

// The only functions you need are reset to see if there is a device on the bus

// Skip to read without address

// Read scratchpad to read temp

#include <inttypes.h>

#include "OneWire2.h"

#define STARTCONVO 0x44 // Tells device to take a temperature reading and put it on the scratchpad

#define COPYSCRATCH 0x48 // Copy EEPROM

#define READSCRATCH 0xBE // Read EEPROM

#define WRITESCRATCH 0x4E // Write to EEPROM

#define RECALLSCRATCH 0xB8 // Reload from last known

#define READPOWERSUPPLY 0xB4 // determine if device needs parasite power

#define DS18S20MODEL 0x10 // Model ID

#define DS18B20MODEL 0x28 // Model ID

#define DS1822MODEL 0x22 // Model ID

// device resolution

#define TEMP_9_BIT 0x1F // 9 bit

#define TEMP_10_BIT 0x3F // 10 bit

#define TEMP_11_BIT 0x5F // 11 bit

#define TEMP_12_BIT 0x7F // 12 bit

// One Wire address

//OneWire2 *pDataWire;

OneWire2 pDataWire(one_wire1_pin);

// 64bit address of device

uint8_t *arSlaveAddr;

// temperature LSB

uint8_t tempLSB;

// temperature MSB

uint8_t tempMSB;

// T(high)

uint8_t highAlarmTemp;

// T(low)

uint8_t lowAlarmTemp;

// device configuration

uint8_t resolution;

void change_pin (uint8_t pin)

{

pDataWire.change_pin (pin);

}

uint8_t get_pin () {

return (pDataWire.get_pin());

}

// read length bytes of a device's scratch pad

void readScratchPad(uint8_t length)

{

// sanity check

if (length > 8) length = 8;

// send the command

pDataWire.reset();

pDataWire.skip();

pDataWire.write(READSCRATCH);

// read the response

for (uint8_t i = 0; i <= length; i++)

switch (i)

{

case 0:

// byte 0: temperature LSB

tempLSB = pDataWire.read();

break;

case 1:

// byte 1: temperature MSB

tempMSB = pDataWire.read();

break;

case 2:

// byte 2: high alarm temp

highAlarmTemp = pDataWire.read();

break;

case 3:

// byte 3: low alarm temp

lowAlarmTemp = pDataWire.read();

break;

case 4:

// byte 4:

// this is really the configuration register, but for

// our purposes, this is how we'll think of it

resolution = pDataWire.read();

break;

case 5:

case 6:

case 7:

case 8:

break;

}

pDataWire.reset();

}

void SetAddress (uint8_t *newAddr) {

arSlaveAddr = newAddr;

}

// Validate whether the current address is correct

int CheckSensor()

{

if (pDataWire.reset() == false) {

return NODEVICE;

}

pDataWire.read_rom (arSlaveAddr);

// Calculate Cycle-Redudancy-Check (ie: check the data is not invalid

if (OneWire2::crc8(arSlaveAddr, 7) != arSlaveAddr[7]) {

return INVALIDCRC;

}

if (!(arSlaveAddr[0] == DS18B20MODEL

|| arSlaveAddr[0] == DS18S20MODEL

|| arSlaveAddr[0] == DS1822MODEL

)){

return INVALIDMODEL;

}

// Return all good

readScratchPad(8); // read the scratchpad to set model, resolution etc

return SLAVEGOOD;

}

// returns a float with the temperature in degrees C.

float getTemperature()

{

// If we're ready to rock, begin communication channel

if (CheckSensor() != SLAVEGOOD) return 0; // return a value outside our range

// The temp is the first two bytes so just request those 2

readScratchPad(2);

int16_t rawTemperature = (((int16_t) tempMSB) << 8) | tempLSB;

switch (arSlaveAddr[0]) {

case DS18B20MODEL:

case DS1822MODEL:

switch (resolution)

{

case TEMP_12_BIT:

return (float)rawTemperature * 0.0625;

break;

case TEMP_11_BIT:

return (float)(rawTemperature >> 1) * 0.125;

break;

case TEMP_10_BIT:

return (float)(rawTemperature >> 2) * 0.25;

break;

case TEMP_9_BIT:

return (float)(rawTemperature >> 3) * 0.5;

break;

}

break;

case DS18S20MODEL:

return (float)rawTemperature * 0.5;

break;

}

}

// sends convert temperature to all devices on the NewOneWire connection.

// only one device on each bus needs to do this. ideally, it should be

// on your highest resolution device so if a delay is necessary, it will

// be long enough

void globalTempRequest()

{

pDataWire.reset();

pDataWire.skip();

pDataWire.write(STARTCONVO);

}

// returns temperature in degrees C

float getTempC()

{

return getTemperature();

}

// returns temperature in degrees F

float getTempF()

{

return (getTemperature() * 1.8) + 32;

}

// Convert float celcius to fahrenheit

float toFahrenheit(float celcius)

{

return (celcius*1.8)+32;

}