I decided to build my new brewery largely based on Kal's "the electric brewery", with a few differences:

- Limited Budget

- Location (240V standard)

- I always brew outside (I live in a rented house)

- The electric circuit in my house is limited... (Will be using a 3kw element)

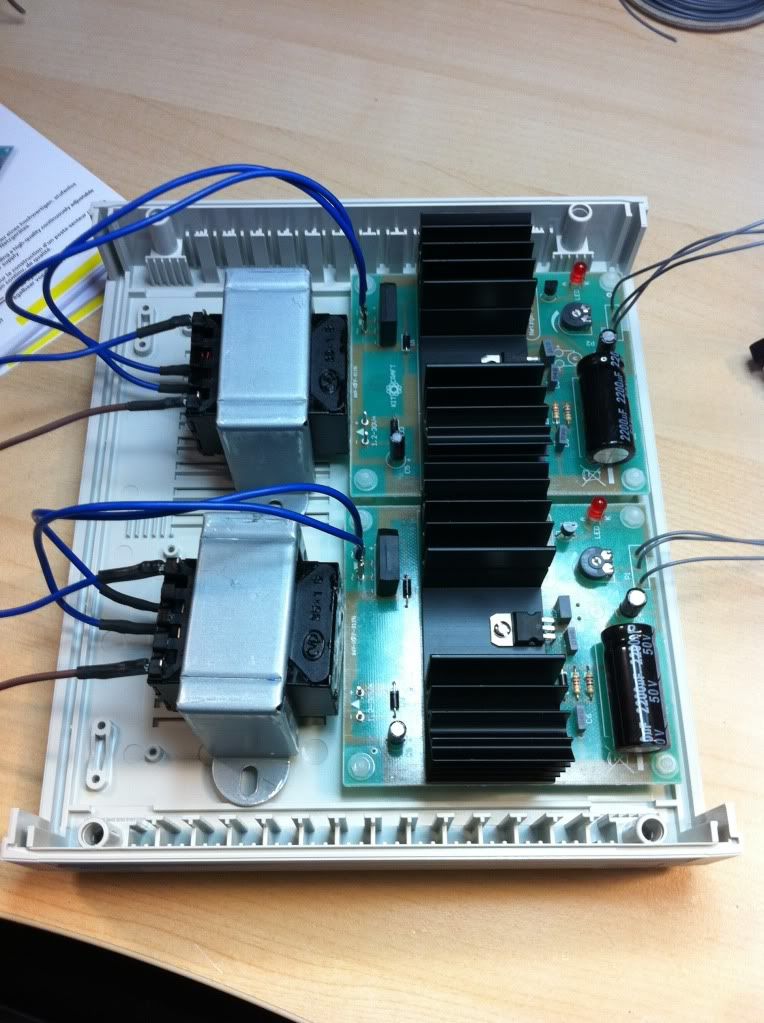

- I am using 12V variable speed pumps (solar project)

Despite all the points above, it is fairly easy to convert Kal's design to fit with my requirements.

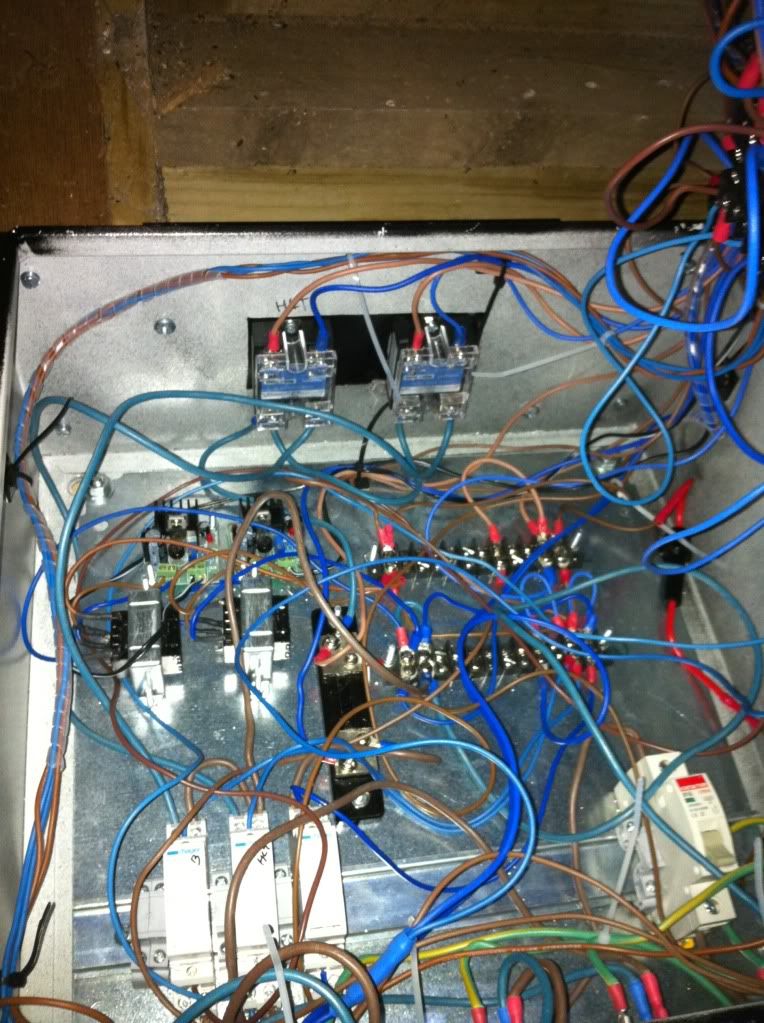

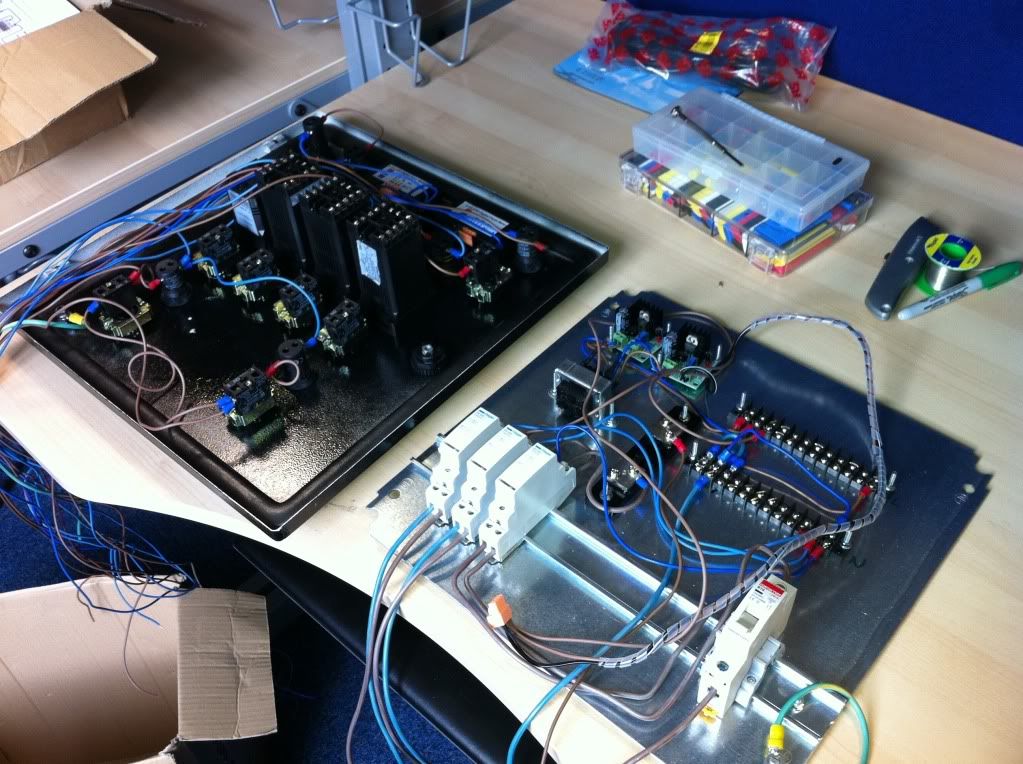

The main differences are the relays. I am using standard Hager contactors that fit nicely on a DIN rail. Note the extra circuit breaker inside the panel:

More components in the control box

The front panel with tags

I started testing the panel and so far so good. The cabinet is grounded properly, the lights all work, relays/contactors seem to work fine. More on the control panel to come in a later post.

The kettle:

I resused some old SS pots that were in a mint condition. The copper pipes you see in the picture at the end of the valves have been replaced by "camlocks" SS quick connectors.

The coil I'm using is from a cornelius in-line cooler (MAXI310). Fits perfectly! Some of the fittings are brass... I will upgrade to SS one day, I promise!

You can also wee the 3kW heating element. I had no real issue with this type of element before, it just takes a little longer to come to the boil than a 5.5kW.

The mash tun:

Nothing too exciting here, appart from the grain filter. This cheap filter worked a treat on my older setup, so I have great hopes for this one.

More later...