http://www.willhi.com/Documents/WH7016Edatasheet.pdf The controller manual.

http://www.ebay.co.uk/itm/280736256740? ... 3D1&_rdc=1 The controller from ebay.

http://www.cedaronics.co.uk/ supplier of enclosure and heat trace cable.

Warning – picture heavy post (well what else do you do after a Christmas meal?!)

So this is the completed heating controller housed in a Cedaronics case controlling a trace heat wire for a condensation boiler. The control unit can be used to control either a cooling or heating circuit as well so has many uses for brewing too such as fermentation temperature control, HLT control etc.

Here is how it was made…

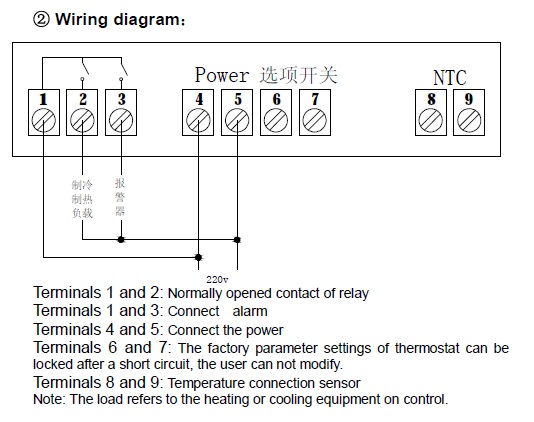

First of all the wiring diagram for the WH7016E. Please note this looks exactly like an STC1000 but although it has the same look and dimensions it doesn’t have the exact same functionality. The major differences are it will only do either heating or cooling – in other words this needs to be selected in the controllers software when powering up for the first time. It only has 5amp relays internally so be aware of the power limitation it can control (or make sure you use a suitable rated relay to switch higher currents). Most annoyingly it has an alarm output – which can be used to trigger other devices when the measured temp deviated by up to 15’C – but it has a internal beeper to let you know! Having said that – it was £10 and ideal for my purposes...read on. Oh they Cantonese bit below No2 reads heating/cooling control and the bit below No3 reads “alarmâ€

First up was making the plugs and sockets up. I’m making two control units, one for me and one for my mum as one of her Christmas presents. One plug and cable is missing as I already have it made up. The plugs/trailing sockets are from Maplin, and are supposedly rubber – although they feel more like a rubberised plastic to me, not like the old fashioned decent rubber sockets. The cable is 2.5mm heat proof cable – and this is definitely rubber based. I chose this in case I decided to put a large current through the cable for controlling a 3kw/13 Amp element.

This is split shot (spot the difference!) showing the compression glands on the bottom of Tim’s (Cedaronics) enclosures – as you can see when the nut is turned it compressed a rubber olive that grips and seals against the cable.

Here is an overview of all the equipment and tools I used. On the far left is what Tim supplied – the enclosures and trace heat cable. In the middle is the cabled up plug and socket, made earlier. You can also see some of the internal wiring with crimped terminals pre-made. Top right is the controller. Bottom right is the Tools: mini-bolt (wire) cutters, electricians screw driver, Stanley knife, crimping tool, wire strippers.

Here is a close-up of the Cedaronics kit. Tim supplies these ready made or as I have got here – ready to make up. The stuff is of very high quality and I’m impressed that he has thought of everything that is needed. The enclosure is pre-cut out to fit the STC-1000 and similar type controllers. He has supplied a gasket to make the seal better to maintain the IP rating. Also there is a loose gasket seal that gets poked around the edge of the box to make it seal. There is a Fuse which I will use to protect the controller. Also a bag of fixings to help, well, fix things in place. For me most of this bag was not required but nice to have in case. You can also see a relay which will allow the controller to power higher currents so the enclosure and the controller can power a 13kw element easily and safely. At the bottom you can see the grommets as show above. One for power input, one for heating output, one for cooling output (not required for my purposes) and one for the temperature sensor. You can also see the trace heating cable which has 1 meter of cold blue wire before leading onto the 2m of black trace heating cable.

close-up of the middle bits!

First job – fitting the gaskets – one for the controller, one for the enclosure that gets trimmed to size.

and fitted. You can see the controller has been fitted making use of the orange retaining clips.

The power in and power out cables are fed through the grommets. I have also attached one of the fuse wires to the power in (No.4) on the controller.

The earth wires have been looped through as there is no reason to earth a plastic enclosure! And the controller/relay doesn’t require an earth. The neutrals are looped with two wires, one for the relay (coil), and one for the controller (No.5). The incoming live is ready to connect to the Normally Open switch on the relay. The live is then also branched off to provide power for the switched live (heating/cooling) on the controller (No.1).

Notice the other fuse wire steals power from the No.1 connection, goes through the fuse before supplying the controller at No.4.

There are several ways that the power can be split but my way of thinking is that the incoming power needs the most direct route to the device that draws the most power, as there is less electrical resistance between connections so minimising localised heating etc for safety reasons, with the other items such as the controller needing far less current.

A step closer.

and all done except the temp probe.

et voila!

and for reference here you can see the wiring diagram on top of the controller. My pigeon-cantonese says that No6 & 7 says “select switch†– or in the manual it says “The factory parameter settings of thermostat can be locked after a short circuit, the user can not modify†or in normal English – the device can be factory locked out by short circuiting between 6&7 to prevent users for messing around with the software settings!

Here is one completed ready to install

initial turn on.

Setting up the controller. Top left = Press set once, then down arrow to lower the target temp to 3’C to switch the power on below this to the trace cable. Top right = hold set down for 3 seconds, and HC is displayed. Bottom left = currently set to cooling mode so…Bottom right = changing the controller to heating mode.

Ready to test. Note the temp readouts in air are around 23’C on both the controller and my handheld temp datalogger.

Dropped the controllers probe in iced water. Here it is reading 2’C and has only just turned power onto the heat trace wire. The handheld probe is between three of the trace heat wires. (you shouldn’t really have the wires overlapping/wrapped up as in theory it could overheat but this was a quick on – off test for a short period. Same for power cables too!)

and the trace cable is heating up nicely – woop woop!

and the finished pair. One got wrapped and then was unwrapped by my mum this morning – she’s chuffed her boiler isn’t going to stop working through freezing temperatures again.

Many thanks to Tim for supplying the controller box and trace heating wire – great quality products.

Merry Christmas

BeerMonsta.

any questions - just ask