The forum for discussing all kinds of brewing paraphernalia.

-

chastuck

- Hollow Legs

- Posts: 345

- Joined: Thu Jul 12, 2012 8:43 pm

- Location: Beckenham, Kent

-

Contact:

Post

by chastuck » Thu Sep 06, 2012 12:30 pm

Last edited by

chastuck on Tue Feb 26, 2013 1:19 pm, edited 2 times in total.

-

DerbyshireNick

Post

by DerbyshireNick » Thu Sep 06, 2012 12:40 pm

*dribbles*

-

dean_wales

- Drunk as a Skunk

- Posts: 991

- Joined: Mon Jul 12, 2010 1:13 pm

- Location: Welshman exiled in Exeter!

Post

by dean_wales » Thu Sep 06, 2012 12:59 pm

WOW. In awe of your DIY skills, thats the most rugged and professional stock pot boiler I have seen.

Congrats.

Click

here for my cider pressing...

Click

here to see my 20% Damson port experiment...

Click

here for red wine from my allotment vine...

-

Fil

- Telling imaginary friend stories

- Posts: 5229

- Joined: Sun Oct 16, 2011 1:49 pm

- Location: Cowley, Oxford

Post

by Fil » Thu Sep 06, 2012 1:13 pm

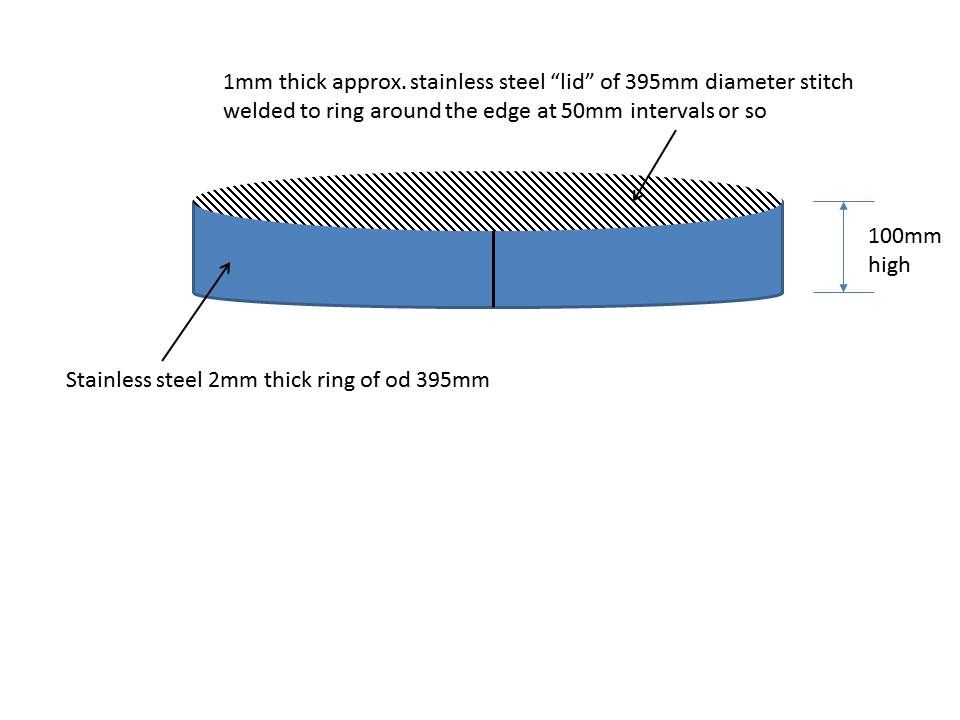

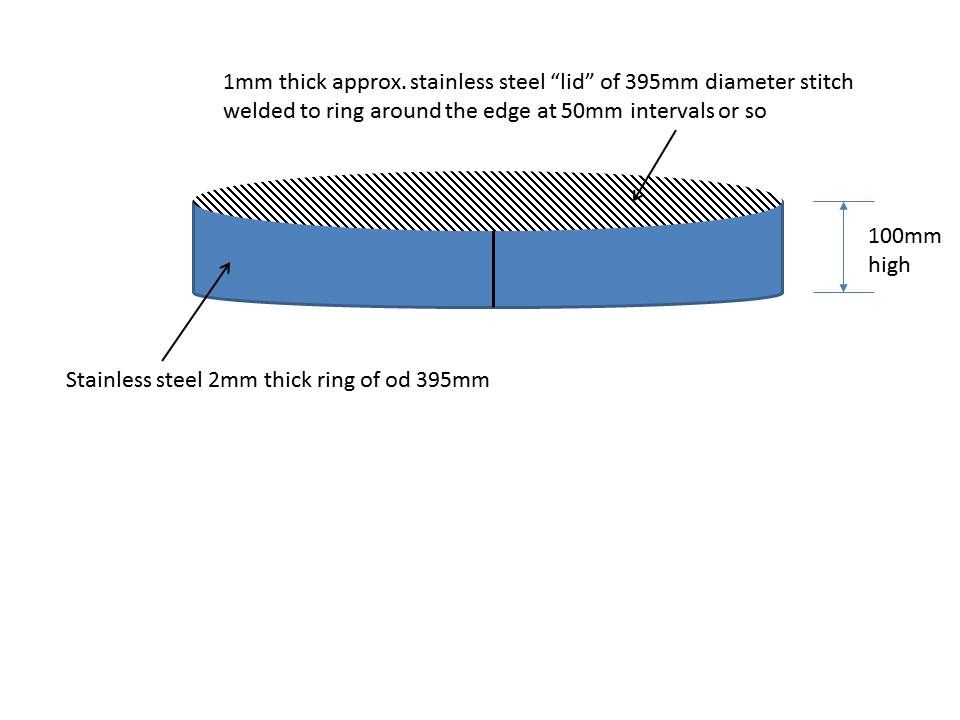

very nice and neat builds, i also liked your mashtun with a similar skirt, what did the ss fabrication set you back? it looks worth it

.

ist update for months n months..

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

-

barneey

- Telling imaginary friend stories

- Posts: 5423

- Joined: Mon Jul 25, 2011 10:42 pm

- Location: East Kent

Post

by barneey » Thu Sep 06, 2012 1:21 pm

How are you finding the acuracy of the combined sight + ballvalve take off? or I`m assuming as its used as a boiler it doesnt matter anyway.

I`ll also be interested in how you get on with the sight tube in the boiler, never tried installing one on the boiler itself due to a few reports of cleaning / discolour issues caused by the wort.

Keep us updated please

Hair of the dog, bacon, butty.

Hops, cider pips & hello.

Name the Movie + song :)

-

chastuck

- Hollow Legs

- Posts: 345

- Joined: Thu Jul 12, 2012 8:43 pm

- Location: Beckenham, Kent

-

Contact:

Post

by chastuck » Thu Sep 06, 2012 1:42 pm

Fil wrote:very nice and neat builds, i also liked your mashtun with a similar skirt, what did the ss fabrication set you back? it looks worth it

.

It took me a long time searching the web and many phone calls before finding steel fabricators that would charge a reasonable cost. The satin finished SS skirts on their own worked out at about £60. The cake stand type skirt was from a different company and cost £110. I bought three catering pots in one go from a German company (50L pot, 70L pot and 50L thermo-pot) and including delivery they worked out at £60 each. So the cost to construct the vessels was not cheap, but still much less than buying them ready made. Plus also of course you get the satisfaction of creating something yourself.

-

chastuck

- Hollow Legs

- Posts: 345

- Joined: Thu Jul 12, 2012 8:43 pm

- Location: Beckenham, Kent

-

Contact:

Post

by chastuck » Thu Sep 06, 2012 1:53 pm

barneey wrote:How are you finding the acuracy of the combined sight + ballvalve take off? or I`m assuming as its used as a boiler it doesnt matter anyway.

I`ll also be interested in how you get on with the sight tube in the boiler, never tried installing one on the boiler itself due to a few reports of cleaning / discolour issues caused by the wort.

Keep us updated please

The vessel is only used as a boiler, so the sight tube is mainly used as a filling aid. It was accurately marked off using a one gallon jug tipped into the pot one jug at a time. During run-off the sight level does go down quicker than than the general water level due to presumably a suction effect, but I either crack the tap open slowly to remove this effect or have learnt from using it how to judge the site level drop and make allowances. So far I have had no discolouration problems with the tube. The bottom of the tube is higher than, and drains into, the 1" ball valve outlet, so I have no problems with left over liquids in the tube. When cleaning the vessel after use I simply squirt hot water into the top of the tube and flush it out via the aforementioned ball valve.

-

Fil

- Telling imaginary friend stories

- Posts: 5229

- Joined: Sun Oct 16, 2011 1:49 pm

- Location: Cowley, Oxford

Post

by Fil » Thu Sep 06, 2012 3:47 pm

chastuck wrote:Fil wrote:very nice and neat builds, i also liked your mashtun with a similar skirt, what did the ss fabrication set you back? it looks worth it

.

It took me a long time searching the web and many phone calls before finding steel fabricators that would charge a reasonable cost. The satin finished SS skirts on their own worked out at about £60. The cake stand type skirt was from a different company and cost £110. I bought three catering pots in one go from a German company (50L pot, 70L pot and 50L thermo-pot) and including delivery they worked out at £60 each. So the cost to construct the vessels was not cheap, but still much less than buying them ready made. Plus also of course you get the satisfaction of creating something yourself.

Less ££s than a prebuilt , then totally worth it, if you had a friendly fabricator willing to do odd little brew jobs in SS it might be a resource worth sharing.

ist update for months n months..

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

-

barneey

- Telling imaginary friend stories

- Posts: 5423

- Joined: Mon Jul 25, 2011 10:42 pm

- Location: East Kent

Post

by barneey » Thu Sep 06, 2012 3:59 pm

Definately a market for the element shrouds, ur friend in Ireland want to make anymore?

Hair of the dog, bacon, butty.

Hops, cider pips & hello.

Name the Movie + song :)

-

Cazamodo

Post

by Cazamodo » Thu Sep 06, 2012 4:44 pm

looking good! Love the skirt idea looks really good. When I finally upgrade to a larger version (keep telling myself not for some time) I may go down this route. I like the elements on the side too whereas mine are bottom mounted.

Ill second an update on how the sight glass hold up in the boiler, I have all the parts for one but never installed it after thinking about how it may discolour. The one on my HLT was originally plumbed like yours but I found i couldnt get an accurate run off so I made it separate. Although mine is all made out of the cheapest [arts I can find, not SS. It certainly looks good! Was that a pre-bought sight glass or did you just order the parts separately?

-

chastuck

- Hollow Legs

- Posts: 345

- Joined: Thu Jul 12, 2012 8:43 pm

- Location: Beckenham, Kent

-

Contact:

Post

by chastuck » Thu Sep 06, 2012 8:26 pm

Cazamodo wrote:looking good! Love the skirt idea looks really good. When I finally upgrade to a larger version (keep telling myself not for some time) I may go down this route. I like the elements on the side too whereas mine are bottom mounted.

Ill second an update on how the sight glass hold up in the boiler, I have all the parts for one but never installed it after thinking about how it may discolour. The one on my HLT was originally plumbed like yours but I found i couldnt get an accurate run off so I made it separate. Although mine is all made out of the cheapest [arts I can find, not SS. It certainly looks good! Was that a pre-bought sight glass or did you just order the parts separately?

I bought all the parts separately from various sources. Had to buy a 2M length of polycarbonate tube, but have used it all now so quite economical.

-

chastuck

- Hollow Legs

- Posts: 345

- Joined: Thu Jul 12, 2012 8:43 pm

- Location: Beckenham, Kent

-

Contact:

Post

by chastuck » Thu Sep 06, 2012 8:31 pm

barneey wrote:Definately a market for the element shrouds, ur friend in Ireland want to make anymore?

This has been discussed quite a lot in these forums. They are made by Mid Cork Metalworks Ltd. Email:

sales@midcorkmetal.ie. Cost varies according to demand, but I paid £62.75 for four including delivery.

Last edited by

chastuck on Sun Nov 11, 2012 5:45 pm, edited 2 times in total.

-

barneey

- Telling imaginary friend stories

- Posts: 5423

- Joined: Mon Jul 25, 2011 10:42 pm

- Location: East Kent

Post

by barneey » Thu Sep 06, 2012 8:37 pm

chastuck wrote:barneey wrote:Definately a market for the element shrouds, ur friend in Ireland want to make anymore?

This has been discussed quite a lot in these forums. They are made by Mid Cork Metalworks Ltd. Email:

sales@midcorkmetal.ie. Cost varies according to demand, but I paid €62.75 for four including delivery.

Thanks for the link, must have missed the posts for em, been looking for a while for shrouds

Cheers

Hair of the dog, bacon, butty.

Hops, cider pips & hello.

Name the Movie + song :)

.

.