I've had an idea to create an automatic system of heating and cooling for fermentation. I'm new here so please tell me if this is old hat.

I thought of this to utilise an old pub beer chiller I've got and a rims heater.

My idea was to use an ink bird controller to measure the temp. But instead of it running an heater. Get it to open a valve allowing water to cycle around a coil in the fermenter and turn on the heater. Then when at temp the ink bird shuts the valve and heater.

Likewise have the same coil in the fermenter linked to the chiller with a valve controlled by the ink bird. The chiller would run constantly to keep the ice block cold. The single pump for the system would run whether hot or cold is called for. It's a bit like a 2zone domestic heating system in a home, just one zone is a beer chiller! Thoughts? I drew a diagram but not sure how to insert it

Rims for fermentation?

-

Fil

- Telling imaginary friend stories

- Posts: 5229

- Joined: Sun Oct 16, 2011 1:49 pm

- Location: Cowley, Oxford

Re: Rims for fermentation?

sounds like the conical temp control implimented by ?wallybrew iirc and similar to what i started to knock up for my conical too.

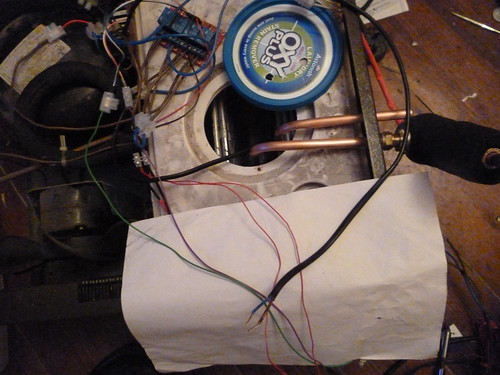

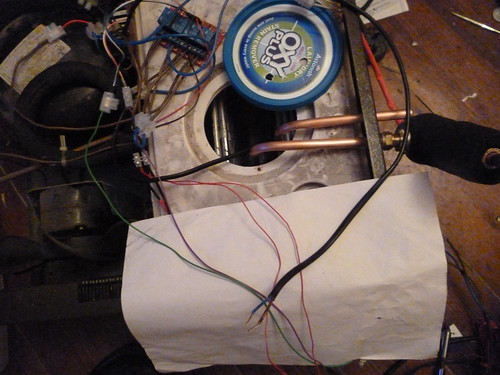

Instead of a rims tube I used 1/2" bsp plumbing bits and a 10mm Stainless steel 400w cartridge element to knock up an inline tube heater, and i strapped a Normally closed Thermal switch rated to turn off @ 40C to the body of the pipe heater to insure against over heating.

I shelved the idea reverting back to a 5m long 75w trace element heating wire designed to heat a reptile enclosure,

there were a few spanners in the works so to say, most crucially the whole waterbath needed changing of its state from heating to cooling when the direction of temperature input need changed. And as my hex coil was a copper coil wrapped around the SS conicals outside not immersed in the beer itself i finally opted to go with the shelf chiller for cold input alone..

But its a workable system if you can ensure your FV only requires input in one direction, If you get into a situation of heating chasing cooling chasing heating, it could get expensive to run too..

My chiller didnt have a recirc pump so i hacked it to fit a water feature pump in the centre of the product coils..

the 400w tube heater set up with 10mm compression fittings for the In/out ports

Go for it

also if you do consider sitting the chiller above the FV as if the hex coil drains between uses it can flood and overflow the waterbath if sat below the FV..

Instead of a rims tube I used 1/2" bsp plumbing bits and a 10mm Stainless steel 400w cartridge element to knock up an inline tube heater, and i strapped a Normally closed Thermal switch rated to turn off @ 40C to the body of the pipe heater to insure against over heating.

I shelved the idea reverting back to a 5m long 75w trace element heating wire designed to heat a reptile enclosure,

there were a few spanners in the works so to say, most crucially the whole waterbath needed changing of its state from heating to cooling when the direction of temperature input need changed. And as my hex coil was a copper coil wrapped around the SS conicals outside not immersed in the beer itself i finally opted to go with the shelf chiller for cold input alone..

But its a workable system if you can ensure your FV only requires input in one direction, If you get into a situation of heating chasing cooling chasing heating, it could get expensive to run too..

My chiller didnt have a recirc pump so i hacked it to fit a water feature pump in the centre of the product coils..

the 400w tube heater set up with 10mm compression fittings for the In/out ports

Go for it

also if you do consider sitting the chiller above the FV as if the hex coil drains between uses it can flood and overflow the waterbath if sat below the FV..

ist update for months n months..

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

- fego

- Lost in an Alcoholic Haze

- Posts: 525

- Joined: Fri May 29, 2009 11:02 pm

- Location: Charlestown, Cornwall

Re: Rims for fermentation?

Surely, the heat generated by the ferment should mean that only cooling is required otherwise you will be heating the beer up to cool it down to heat it up again.

I use a flash cooler to pump cold water through the fermenter but have never found the need to heat it up again. Once back down to the set temp, it creeps back up and the cooler kicks back in when needed. I do have a heater in the chamber that will come on if it cools too low, but that is only there to balance ambient temperature on really cold days.

Not sure there is a problem to your solution unless it means enabling an absolute constant temperature throughout the ferment compared to the up half a degree, down half a degree, up half a degree fluctuation I experience....

I use a flash cooler to pump cold water through the fermenter but have never found the need to heat it up again. Once back down to the set temp, it creeps back up and the cooler kicks back in when needed. I do have a heater in the chamber that will come on if it cools too low, but that is only there to balance ambient temperature on really cold days.

Not sure there is a problem to your solution unless it means enabling an absolute constant temperature throughout the ferment compared to the up half a degree, down half a degree, up half a degree fluctuation I experience....

Tea is for mugs...

- Kev888

- So far gone I'm on the way back again!

- Posts: 7701

- Joined: Fri Mar 19, 2010 6:22 pm

- Location: Derbyshire, UK

Re: Rims for fermentation?

The heat from fermentation can only raise the temperature by so much. It depends on the ambient temperature, batch size and insulation/losses involved, as well as the yeast strain (amongst other things); for some people it isn't enough. The period of significant heating is also relatively short; if the fermentation cools too much towards the end it can take longer to finish, or even stop.

I most definitely needed heating when I fermented in an unheated garage, for quite a percentage of the year. Even 100L batches with thick insulation could not maintain ale-yeast temperatures in winter. I occasionally need heating indoors, in winter the fermentation only manages enough self heating at around it's peak.

It also isn't just a matter of keeping the yeast within its working temperature range. Fermentation temperature can affect the flavour of the finished beer, so keeping it within a smaller range is needed for improved consistency and in some cases fine-tuning of the yeast character.

I most definitely needed heating when I fermented in an unheated garage, for quite a percentage of the year. Even 100L batches with thick insulation could not maintain ale-yeast temperatures in winter. I occasionally need heating indoors, in winter the fermentation only manages enough self heating at around it's peak.

It also isn't just a matter of keeping the yeast within its working temperature range. Fermentation temperature can affect the flavour of the finished beer, so keeping it within a smaller range is needed for improved consistency and in some cases fine-tuning of the yeast character.

Kev

-

extremeds

Re: Rims for fermentation?

Thanks for input, I'll be brewing in an old grain bin. On a farm, it looks the part but will be very cold in winter as it's under insulated at the moment, but I intend to insulate and ply line it out. But it would never be as warm as a house in the winter. Hence the heating idea. Was thinking of using a standard domestic immersion element for the heating as they come with their own adjustable thermal cut out.

I.want the heating coil that sits into the FV to be easily removable for cleaning. With the heater/cooler and pipework more static. As things progress I could add more valves into he pipework to feed other FVs from the same heating cooling loop.

Perhaps!

I.want the heating coil that sits into the FV to be easily removable for cleaning. With the heater/cooler and pipework more static. As things progress I could add more valves into he pipework to feed other FVs from the same heating cooling loop.

Perhaps!