Old Ale - Burton

This is a Pre WW1 interpretation of the beer that gave rise to the phrase 'Gone for a Burton' when a number of munitions workers were killed when the pub was bombed during an air raid.

7.17kg Maris Otter Pale Malt

312g Flaked Maize

468g White Sugar

31g Caramel

109g Fuggles - 90 mins

109g Goldings - 90 mins

Yeast - about 250g Hook Norton slurry

Target OG 1075. 52L liquor prepared and boiler set to fire up at 6.45am tomorrow.

Up at 7.45am. A couple of pics while waiting for strike heat in the boiler.

Fugggles...

Goldings...

Mashed in at 8.30am. Boiler at 77c, underlet 17L liquor, initial heat 68c, let drift down to 66c while stirring, testing. Was careful with CRS this time. 22ml in boiler + 9G DLS in grist gave PH 5.5 in mash. Better. Adjusted to 5.2 with 5ml lactic acid. mashed 90mins...quick routine starch test, as usual and.... Non convertus est!

Uh oh! THE CALAMITY! Can only think that 77c was too hot and weakened the enzymes even though mashing in only took 5 mins and that it would have been in the safe zone even sooner than that. Stir, wrap it up again, and 30 mins later it was better but not totally converted. Same again, and 30 mins later again it was done, mash temp then 62c-ish which probably helped.

Outdoor setup in front of prospective brewshed

Outdoor brewstation

Sparge Liquor temp required to hit...

...this grain bed temp.

Monitoring grain bed temp

First wort - clear. Note, hop strainer

Hot break, or is it?

Just a few hops, then

Hop boil

Preparing evil adulterants - Andy, your secret's out!

In they go..note look of distaste

Darker wort now! Sterilising chiller

Assembling fermentation cooler

Wort in place

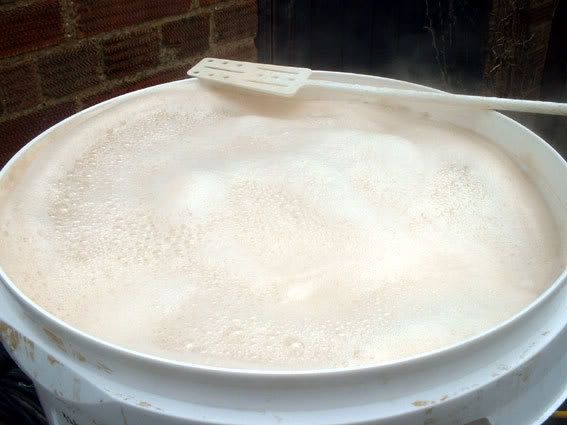

After 18 hrs...Quatermass And The Yeast!

After 44hrs...Anaerobic ferment..make that alcohol! Note, there's about 3 inches depth of yeast

Currently changing 12L of water about 3 times a day to keep ferment under 20c, what with it being warm out.