My setup

First job was to fill my HLT and get that upto 77deg. To keep things as simple as possible on my first brew, I intend on batch sparging. After working out my two batches of water I filled the first batch to 19.9 ltrs, the 2nd batch was to be 15 ltrs. Adding 1/2 cambden tab

My HLT

While this was getting upto temp, (used a jam thermometre clipped on the side of the HLT) I started my yeast off by adding preboiled water (20deg) to rehydrate and to this added 1 tsp suger that had been disolved in water and allowed to cool to 20deg.

next was the grain bill to measure out.

Grain added to my Mash Tun and doughed in checking that there were no lumps left in the corners.

The first batch of liquor was added (77deg) and this ended up at 67deg when mixed to the cold MT and the grain mixed. The Coolbox MT was very good, the only small problem was that the tap seemed to be very hot, so this was lagged with a tea towel to preserve heat. After a hour I added another 15 litres of liquor to my HLT for the second batch sparge, this was to be slightly cooler at 70deg.

The Hops were now measured out

After 90 mins, the MT tap was opened up and after recircing about 3 litre of wort it then seemed quite clear. I took a sample at this point and the reading came out at 1050 @ 60deg, I then took a further two litres to a pan to boil down to a litre as suggested by someone on this site. The boiler was turned on after covering the element

Now the 2nd batch of liqor was added to the Mash Tun and allowed to filter through into the boiler. After the required amount was gathered I took another sample and this read 1010 which seemed ok. With the boiler now in a rolling boil, the hops were added.

The last 15 mins of the boil, the wort chiller was put in the boiler to steralize it, also the wort that had been reduced to 1 litre, the remaining hops and Irish Moss were added

After 90 mins the chiller was turned on, I was very suprised at how hot the water on the outlet of the chiller got, after 5 mins the temp came down from 100deg to around 60deg and I thought i would be down to 20deg in another 5 mins, I soon realized that it dosent work like that as the wort is cooling the drop gets slower, I also noticed that agitating the chiller in the wort was a lot more efficient then just letting it sit there and also put a bit of air back in the wort.

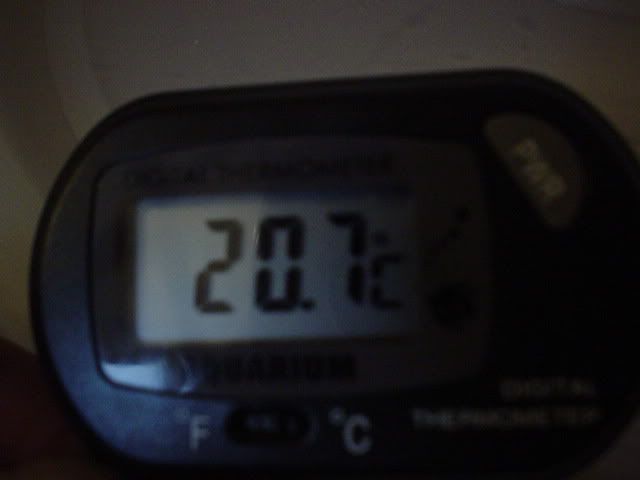

After around 20 mins the wort was at the desired temp of 20deg, this was then transferred to the fermenting vessel. another hydrometre reading was taken reading 1046 @ 20deg

With yeast pitched the digital thermometre probe (after been steralized) was inserted into the fermenting vessel

Will let you know what it taste,s like in about 6 weeks time.