Out of the experience i learned a few things

1) when you run the water through the chiller that's been sitting in boiling wort for 10 mins, the water that comes out is quite hot

2) it takes a long time for 23l of liquid to get to the boil.

3) don't measure the volume and then add the extract. I know, I know... It's a learning experience!

Anyway, here's the recipe

3.6Kg pale LME.

50g Northdown (8.7%) - 60mins

20g First Gold (6.3%) - 10 mins

20g Styrian (4.5%) post boil.

safale s04.

Everything went pretty well. My new boiler really got the rolling boil going. Chiller worked a treat (i don't know how effective i expected it to be, but it was amazing) and today it's fermenting away like crazy. smells fab. It's going to be quite hoppy, which is exactly what i was after. The only thing that threw me was that i got a much lower OG than i'd been expecting. BeerEngine predicted 1047, but when i measured it when it went into the FV, even after correcting for the temperature, it was 1042. Obviously i lost some wort in the hops, but not that much, surely. Anyone got any ideas on what i might have done wrong to be so far off?

Here's the fun part. First the hops:

This is just nearing boiling point.

Finally hit boiling point

Rolling boil. I never really understood that term until i saw it

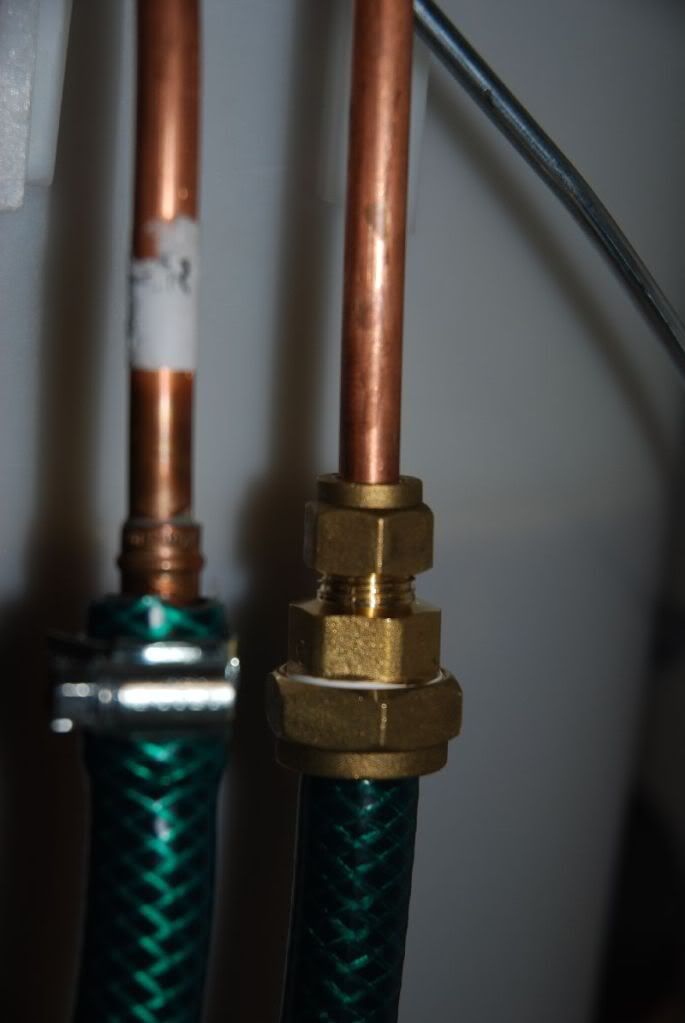

My plumbing solution for an H&G Chiller. The inward flow is easy, but the outward flow meant finding the right fitting at B&Q.

The wort running off into the FV

My unexpectedly low OG.

The stuff left behind at the end. Even that smelled great!