AG3 - great big bucket of Lager

Posted: Sun Jan 23, 2011 10:42 pm

stocks of AG2 depeleted- It was time for affirmative action.....

and so to work. I scaled up the previous recipe using the wonderfully free beer engine (thanks GW) and armed with strike heat, water treatment,batch sparge calculators from Jims Beer Kit I embarked upon the big one - featuring my 50L stock pot and big burner of propane for the first time in anger

water in, added to the grains : much stirring and (you'll have to take my word for it) the thermometer showed 67 deg c.. a good start !

running off/batch sparge action featuring ss colander from pound shop

rolling rolling boil , this burner can handle WAY more than 5 gallon batches- need a bigger mash tun though !

left overnight to cool and then painstakingly jugged into a FV via the pound shop colander.

so...as we are all supposed to do at work... what went well etc...

+Boil- easy to get a rolling boil, fast heat up times.

-tricky to balance heat input to get a stable temp for strike. I can see MAYBE a HLT in the near future (its made but i would add 1x kettle element and thermal control )

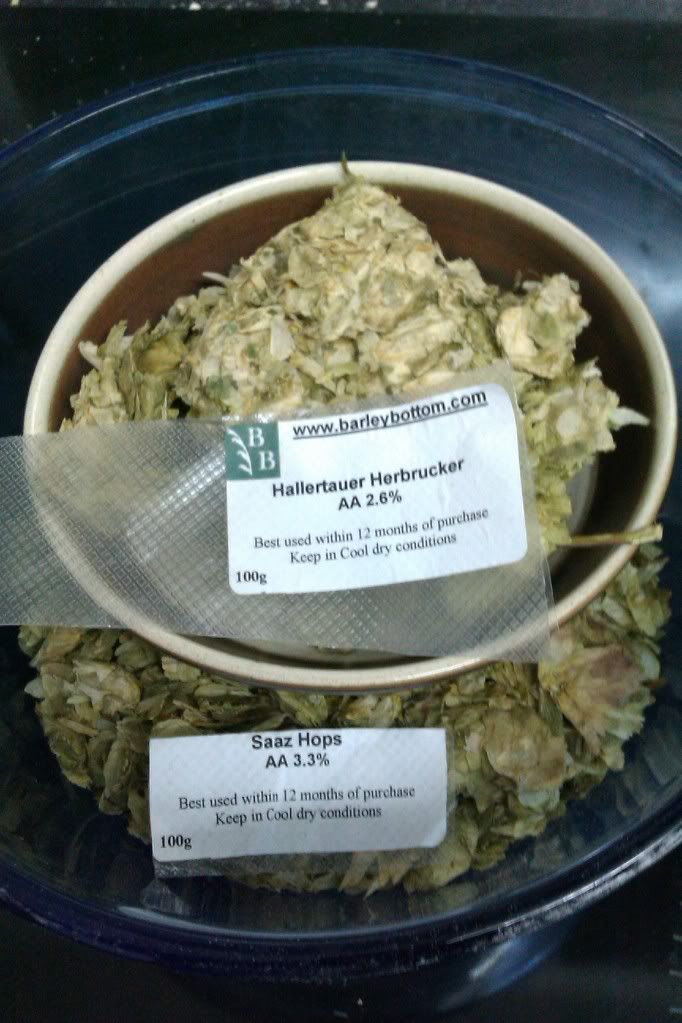

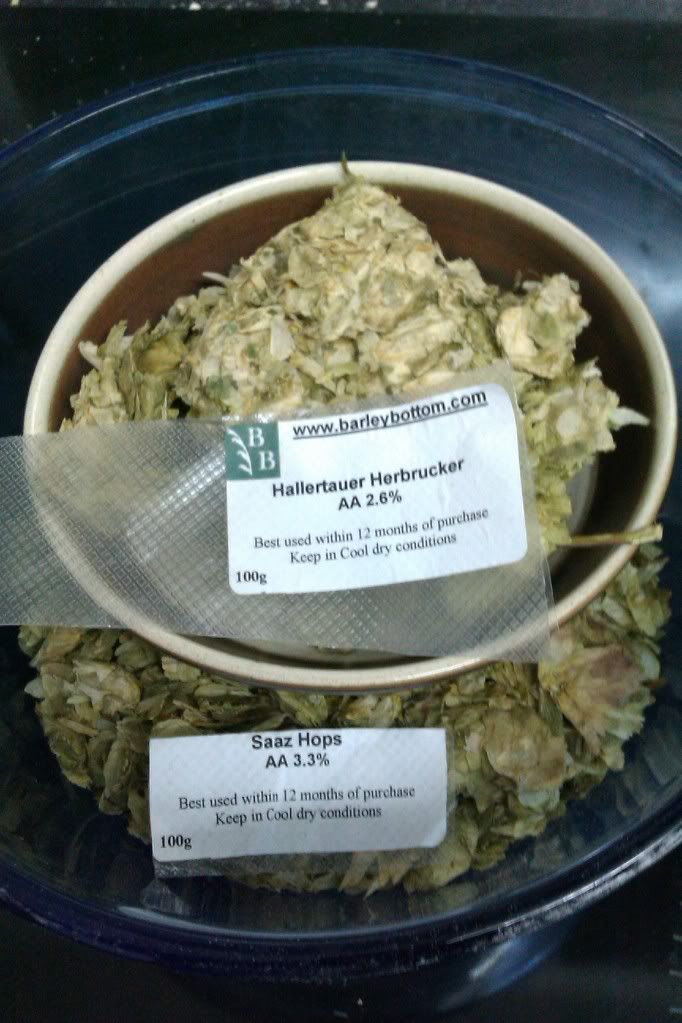

+Hops where vac packing has remained intact and have been in freezer are still fresh after a long long time

+CRS / gypsum brought the OG in on the nose

-jugging the wort out of the copper is a bad idea. I will make a hop strainer. this also means i want the copper up higher: gravity is free.

bottling 40+ pints may be a PITA but it sure saves the hassle of gas and regs !

AG4 will be an ale ... promise.... and i'll resize those pics soon as well !

and so to work. I scaled up the previous recipe using the wonderfully free beer engine (thanks GW) and armed with strike heat, water treatment,batch sparge calculators from Jims Beer Kit I embarked upon the big one - featuring my 50L stock pot and big burner of propane for the first time in anger

water in, added to the grains : much stirring and (you'll have to take my word for it) the thermometer showed 67 deg c.. a good start !

running off/batch sparge action featuring ss colander from pound shop

rolling rolling boil , this burner can handle WAY more than 5 gallon batches- need a bigger mash tun though !

left overnight to cool and then painstakingly jugged into a FV via the pound shop colander.

so...as we are all supposed to do at work... what went well etc...

+Boil- easy to get a rolling boil, fast heat up times.

-tricky to balance heat input to get a stable temp for strike. I can see MAYBE a HLT in the near future (its made but i would add 1x kettle element and thermal control )

+Hops where vac packing has remained intact and have been in freezer are still fresh after a long long time

+CRS / gypsum brought the OG in on the nose

-jugging the wort out of the copper is a bad idea. I will make a hop strainer. this also means i want the copper up higher: gravity is free.

bottling 40+ pints may be a PITA but it sure saves the hassle of gas and regs !

AG4 will be an ale ... promise.... and i'll resize those pics soon as well !