Ok, invoices done.

I'd prepped liquor to just under ph6 with lactic acid.

Mashed with 16.5L.

Strike heat 74c

Initial heat 66c

Ph was 4.9. I didn't think lager malt would have dropped it that much. Know better next time. Never mind.

90 minute mash, finish at 66c. No heat loss.

Heated 'sparge' liquor to 85c

6kg malt and 0.25L dead space so 7.5L added to get an 18L 1st run (72.5c mash bed) 18L got, at 1059

2nd run: 14L added. (note: for max efficiency, should be 18L, but I'm under extracting deliberately) at 83c. 75c mash bed. 14L got at about 1023. Combined was 32L at about 1044, topped to 38L preboil with more liquor.

Boil..foam up, bung in 146g Saaz. 146g because that was a whole 113g pack. Told you it was generous. This is where things started to go wrong...the phone didn't stop ringing, and I got behind. I was busy rigging my cooling contraption (see below) and running sanitiser through it (VWP - proper chlorine/caustic stuff. Sod idodine.) and the FV. The return pipe was taped to the side of the FV.... I was on the phone....the tape gave way........the pipe snaked out of the FV....nobody noticed....the little trusty totton pump carried on cheerfully pumping out about 2 gallons onto out laminate kitchen floor........colourful language ensued when I got off the phone and wandered into the kitchen to rinse the cooling contraption.

Consequently the boil went on 30 mins longer, 2 hrs total, then 60g Saaz went in at 1min to switch off - and a long wait as I mopped up the kitchen floor before the steeping hops went in - at 65c, not 80c. 30g Saaz

Still, the phone did not stop. There was no time for a cheese platter

Oh, and it rained.

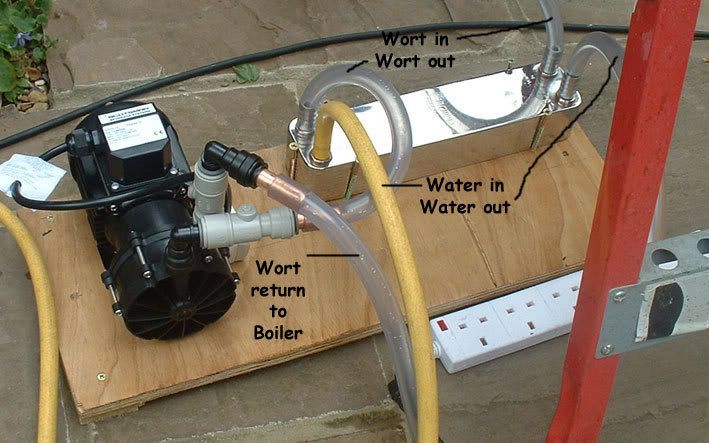

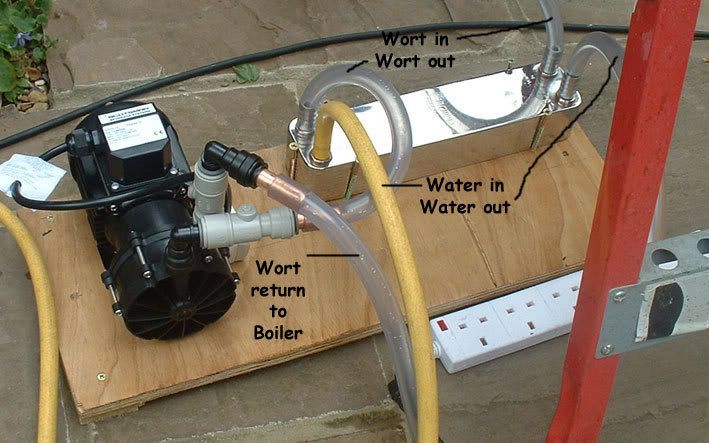

Cooling was effected by the contraption below.

I recirculated a couple of jugs to reduce the ammount of detritus hitting the chiller and pump - in the end thought sod it..let's see if it copes. It did. No flow restriction through the chiller but I choked the totton pump so as not to draw too much crud through, and not to create a tidal wave in the boiler as I returned it. The pump was after the chiller because the pump has an 85c max liquid temp. Cooling was very fast and the recirculated wort ran nice and clear. Eventually directed to the FV I got 24L, as

expected, at 19c. OG 1053 Must have knocked an hour off my cooling time.

A bit more detail

The chiller is a Mashmaster Chillout 20 plate chiller from Ross at Craftbrewer in Australia. Barbed fittings a doddle, just plonk the hose on. Sweet. Not expensive, either. It's bloody good. I backflushed it afterwards. Very little crud was trapped. Must have a good flow path.

The pump is a Totton GP20-12 magnetically coupled, from Norman. New, £45 including delivery and, JG fittings, which included ball valves. I got 2 of them. Same as the ones Seveneer has.

Oxygenated with a 4 min burst of O2 while 14 tons of saflager S23 was rehydrating. The pack said sprinkle dry onto wort. I just couldn't. But...maybe I should. It was a pig to rehydrate. Sticky claggy mess, but I won in the end.

It's well underway with a fluffy 3" head, at room temp. I'll now stick it in the fridge at 12c for about 10 days, then give it a diacetyl rest by bringing it up to 16c over 2 days then gradually drop it to about 4c over about a week, then keg/bottle it after about 3 weeks, and leave it for about a month. That's the plan.

Extraction efficiency was 77%. Brewhouse efficiency was 69.5% Last brew I'd taken a 12L 2nd run as opposed to 14L this time and got 75% / 65% so it appears fairly consistent. if I'd taken 12L this time It might have been 1050 and 65% brewhouse (can't be arsed to work it out.)

Phil, It's more or less Ant's schedule, except he goes down to near 0c after the diacetyl rest. Don't think my fridge will go that low. The freezer will, but it's full of beer that won't appreciate being frozen.

Right...to the shed!