Target Gravity is 1.048 for 28L

2850g Lager Malt 49.57 %

2600g Wheat Malt 45.22 %

300g Acid Malt 5.22%

10 gm Endevour[7.3% %] (75 min) Hops 6.1 IBU

11.5 gm Mandarina Baveria[8.9 %] (75 min) Hops 9.4 IBU

2 packs of Fermentis WB06

14 ml crs

3g Calcium Chloride.

2.1g Gypsum

Mash in 27.5L at 38C

Step 1: 30 Mins @ 62C

Step 2: 40 Mins @ 72C

Mash Out: 10 Mins @ 78C

Sparge 13L @ 78C

Grain shot:

Mashing in. I find with a large percentage of wheat malt it take up less space for the weight. 5.75kg of only barley malt would have been a struggle but no problems fitting this lot in:

Pumps on:

Shot of the brewery. The BM will eventually stay back against the wall once we have sorted out the steam issues. Pretty compact for what will be a 10 gallon brewery.

I have this waiting in the wings. Its been fitted with a thermowell, a stainless cooling coil and 2 x 25 watt flexible heat mats from a reptile shop. I will use a maxi 110 shelf chiller for the cooling once it arrives. Hopefully i will get to use it soon.

Mashing done:

Malt pipe lifted. I can do the short malt pipe by hand but for the large malt pipe lift i have a pulley hoist waiting to be fitted.

Sophisticated steam management system. Ducting + stick + bungees + duct tape worked surprisingly well. In the bend there is a hole to let the water drain into the pan. The original plan was to use a bathroom extractor fan and route the steam out of a window in the roof via the flexible ducting. Unfortunately during a test when the ducting got hot it collapsed with the suction and water spewed out the bottom of the fan.

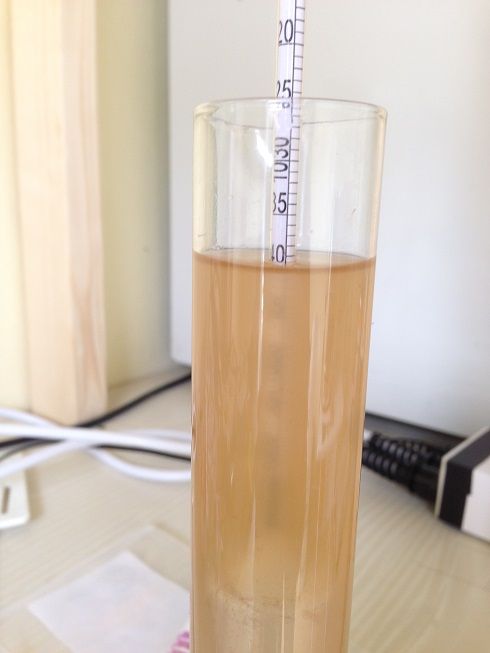

Pre boil gravity right on target:

Setting up the recirc pump, plate chiller and siphon stick. Slight issue with the pump as it would not get going. Turns out one of the connectors was shorting out so i quickly cut it off and used a connector block to get it going again.

Run off:

OG Reading right where it should be:

Very little leftover when using the siphon:

A new addition to the brewery - temp controlled fridge. This will have several duties, when doing smaller batch sizes i will use it for fermentation temp control otherwise it will be used as a kegerator. I can get 2 20L sankey kegs in there. Despite doing 58 brews this will be the first one where i have some decision in the fermentation temperature. For this beer i set it at 22C. Fermentis recommend under 22C for clove flavours and over for banana - at 22 i'm hoping for a bit of both.Thermowell goes through the lid for the temp sensor, on the Speidel fermenter above it wasn't long enough to reach the wort so it went in through the front:

Quick peak the next morning and fermentation is well underway: