Page 1 of 2

Brew Day 14 May 06

Posted: Sun May 14, 2006 8:39 am

by eskimobob

Waheeyy time to brew

Currently mashing in the new mash tun (converted coolbox). The temperature is holding up amazingly well at the moment; it has not moved in the first 30 mins.

Here's today's recipe:

2500g Pale malt

400g Roasted Barley

1000g Flaked Barley

57g Fuggles (for last 60 mins)

5g Irish Moss (for last 15 mins)

I filled my baby burco last night with tap water and put in half a campden tablet. This morning heated to 77C and then run off 11 litres into the mash tun (74C) and waited for it to drop to about 72C. Added all the pale malt and the temperature was still very high so I added in about a pint of cold water before adding the rest of the grist. Temperature was then a bit low so I added in about another pint of boiling water to get it up to about 64C.

Mashing for 90 mins at about 64C.

Posted: Sun May 14, 2006 9:12 am

by Bigster

good luck eskimobob.

I think your coolbox is better than mine - I think mine must be a 'cool'box - the temp had dropped from 66 to 64 after 45mins. added some hot water. Fingers are crossed....

Posted: Sun May 14, 2006 9:48 am

by Andy

Bigster, had you preheated the tun with boiling water for 15 mins or so ? And covered it with additional insulation (blanket, sleeping bag etc) when mashing ?

EB, best to do temp. compensations when all the grist is in the tun!

Posted: Sun May 14, 2006 9:58 am

by Jim

Nice one, EB. Best of luck!

Posted: Sun May 14, 2006 10:55 am

by eskimobob

Just started the boil now

The mash went well and I used my new hop strainer thing as a mash filter in the coolbox which worked like a dream - the run off was nice and steady. I now need to sort out one of those spinning sparge arms; make or buy ? <_<

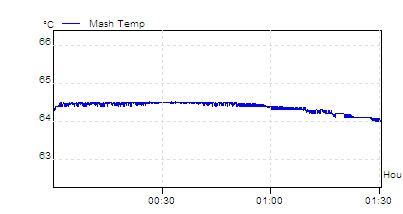

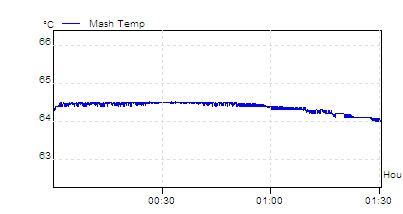

I'm amazed at the difference in coolbox thermal performance when filled with grain. You guys were right for sure, the temperature drop was less than 0.6C - perhaps the extra insulation was worth adding afterall - see graph below:

The wort is a nice dark colour

Posted: Sun May 14, 2006 11:32 am

by Bigster

Well done EB

I have got a spinny sparger - you have done well with your sparging. Fancy doing mine next time

Posted: Sun May 14, 2006 1:14 pm

by eskimobob

Well the boil went well but then arghhh! My newly made counterflow wort cooler was a big disappointment

I had it all set up and was planning on running a couple of litres of hot wort through and returning it to the boiler for sterilising before turning on the cooling water but I never got that far. The wort refused to flow through the cooler! I could get some to flow if I sucked on the outlet end so to begin with I thought my new hop strainer was clogged up - a bit of stirring went on; nothing but a dribble. I then managed to detatch the hop strainer with the aid of a knife to undo the nut holding it on to the tap but again nothing but a dribble.

After detatching the CFC and running into the FV (which is now cooling in the bath), it occurred to me that I was probably not helping in trying to feed the wort from the boiler into the bottom of the CFC. The idea was so that it would come out of the top which was resting on the FV and then fall in to the FV aerating on the way. Perhaps the friction in the 8mm microbore is too much for that to work. I had plenty of height from the boiler so gravity should have been on my side.

Do you think this was the problem? :huh:

The only alternative I can think of is to get a pump and pump it through the CFC from the boiler.

Posted: Sun May 14, 2006 1:25 pm

by Andy

Hmmmm, I set my CFC up so that the wort runs through it under gravity i.e. hot wort enters at the top and cold cooling water comes in at the bottom. Mine also uses 10mm microbore so more flow potential. Others on here use 8mm I believe!

I can recommend testing newly constructed kit before brewday

Posted: Sun May 14, 2006 2:57 pm

by Jim

Regarding the CFC, mine runs in at the top and out the bottom. You need as much head of liquid as you can get to allow it to run through by gravity alone; inverting the direction of flow effectively reduces your head.

Posted: Sun May 14, 2006 3:17 pm

by eskimobob

Ok, thanks guys - looks like I have learnt a lesson there :rolleyes:

I have just tried it in the sink with a jug of water and a funnel and it seems to work like that; perhaps the combination of doing it upside down as it were, the small bore on the boiler tap and the hop filter was just too much. I'll try again next brew.

The wort is now cool enough so I have just measured the OG (1042) and pitched the yeast starter

Posted: Sun May 14, 2006 8:01 pm

by eskimobob

I was just wondering why there was no obvious yeast activity 5 hours after pitching when it suddenly dawned on me; with all the kerfuffle over the chiller not working as expected, I forgot to aerate the wort before pitching the yeast

I've therefore run it from the FV into the mash tun (lots of splashing) and then back into the FV (again lots of splashing). I just hope the yeast gets itself into action quickly now. Wish I had some of that explosive stuff that Andy got

On the plus side, I got a huge amount of foam generated so I guess that bodes well for head formation and retention.

Posted: Sun May 14, 2006 8:20 pm

by FlippinMental

nice going for you first brew, my first was a bit chaotic. once you fine tune the kit and get a routine sorted things tend to get a bit better each time.

It’s my experience that you don’t usually see much yeast activity until about 8 to 12 hours after pitching, but this can vary greatly for all sorts of reasons.

Posted: Sun May 14, 2006 8:37 pm

by eskimobob

Hi FM, it's not actually my fist AG brew (although I agree that it looks like it as it went a bit pear shaped today), it's my fourth this year but I have only just started brewing AG again this year after many years of infrequent kit brews. I've been building up my equipment having given most of it away years ago.

In my last brew I used White Labs yeast and had a yeast head within a couple of hours so I was expecting the same thing as I've used White Labs yeast again (albeit the Irish Ale yeast rather than the English Ale yeast). Oh well, we'll see what happens now it's had a good aeration...

Posted: Sun May 14, 2006 9:04 pm

by full malty

QUOTE (eskimobob @ May 14 2006, 07:39 AM) Waheeyy time to brew

Currently mashing in the new mash tun (converted coolbox). The temperature is holding up amazingly well at the moment; it has not moved in the first 30 mins.

Here's today's recipe:

2500g Pale malt

400g Roasted Barley

1000g Flaked Barley

57g Fuggles (for last 60 mins)

5g Irish Moss (for last 15 mins)

I filled my baby burco last night with tap water and put in half a campden tablet. This morning heated to 77C and then run off 11 litres into the mash tun (74C) and waited for it to drop to about 72C. Added all the pale malt and the temperature was still very high so I added in about a pint of cold water before adding the rest of the grist. Temperature was then a bit low so I added in about another pint of boiling water to get it up to about 64C.

Mashing for 90 mins at about 64C.

Crikey, that seems like a massive amount of flaked barley in relation to pale malt.

For a 10 gallon brew, I usually use around 8-9kg of pale maybe 1kg of flaked barley.

Posted: Sun May 14, 2006 9:05 pm

by FlippinMental

sorry about that EB, spent too long in the sun digging a hole today.

about yeasty things - i've been trying to reactivate yeast from summer lightning, after about 24 hours of nervous waiting there's definitely something going on thank the brew lords