Keg Pressure / Beer Line / Force carbing question

-

dmdrabble

Keg Pressure / Beer Line / Force carbing question

Hello,

I was hoping to get some advice on my Keg / Freezer / Gas line setup. I have read various forums and watched so many videos that I have confused myself.

I have got 3 kegs set up in a chest freezer, with the temperature controlled using a STC 1000 device from Amazon, which works very well.

I have a German Wheat in one keg and a San Miguel clone lager in another. I understand the Wheat beer and lager need to be quite lively, so need to have a good level of CO2. The problem is I have lots of foam and not enough fizz.

Quick rundown of the set up.

- 6 feet of 3/8 OD tubing to each tap from outlet

- Temp probe into a pint glass filled with water – temperature set to 6 degrees C, with 2 degree tolerance

- San Miguel in the Corny and Wheat Beer in the Sanke.

Because my kegs are inside the freezer, I wanted to try to set and leave method. One American forum suggested connecting Gas to the liquid out and letting the Gas bubble up through the beer. This sounded logical, so that’s what I did. Others suggest just connecting to the Gas in and leave.

- First attempt – set the pressure to about 10 psi for a week. Not much foam, but not fizzy enough.

- Second attempt – crank up to 20 psi and leave for a few days. Bleed off pressure and set to about 5 psi to serve. Still not fizzy enough.

- Third attempt – Crank up the pressure past 20 psi and leave for a week. Bleed off the pressure and now I have far too much foam, with not a great deal of fizz. I did notice that the beer didn’t seem cold enough, so I set the temp to 4 degrees C, with the 2 degree tolerance.

- Forth attempt. I have cranked it right up to 40 psi and left it for 2 days. Haven’t tried it yet.

So I suppose my questions are as follows:

- Put Gas on the beer out post for carbing or just straight on the gas in? Looking at the tables for style of beer I have, pressure at 10 to 13psi looks about right for 4 degrees C. If you leave at this pressure, will you get loads of foam, given the length of beer line? If you reduce to 5psi, will the level of CO2 in the beer drop and you get flat beer?

- There are two schools of thought – 1. Set the pressure very high for a few days and bleed off, and then reduce to around 5psi for serving. 2. Set to around 10psi for two weeks, and then leave at this to serve the beer.

- Should I just take each keg out and do the rolling quick thing for now, while I get the hang of it?

- Length of beer line – Mine is 3/8 OD. I have seen equations for length / diameter and lift, but my pipes just sit on the top of the kegs. I have cut mine to 2M /6ft. Does this seem OK?

- Is the probe stuck in a pint glass of water representative of the temperature in the keg? I like my beer cold.

I have done so much research, looking at John Guest fitting, freezer sizes, wiring up a STC1000 controller and sanke couplers. I haven’t even mentioned the in/out ball locks or the stubborn centre tube and filling a Sanke keg yet.

I apologise if this has been answered on a number of occasions, but I think I have got myself very confused, reading one forum after another and watching one

Youtube video after another. Any tips would be greatly appreciated.

Thanks. David.

I was hoping to get some advice on my Keg / Freezer / Gas line setup. I have read various forums and watched so many videos that I have confused myself.

I have got 3 kegs set up in a chest freezer, with the temperature controlled using a STC 1000 device from Amazon, which works very well.

I have a German Wheat in one keg and a San Miguel clone lager in another. I understand the Wheat beer and lager need to be quite lively, so need to have a good level of CO2. The problem is I have lots of foam and not enough fizz.

Quick rundown of the set up.

- 6 feet of 3/8 OD tubing to each tap from outlet

- Temp probe into a pint glass filled with water – temperature set to 6 degrees C, with 2 degree tolerance

- San Miguel in the Corny and Wheat Beer in the Sanke.

Because my kegs are inside the freezer, I wanted to try to set and leave method. One American forum suggested connecting Gas to the liquid out and letting the Gas bubble up through the beer. This sounded logical, so that’s what I did. Others suggest just connecting to the Gas in and leave.

- First attempt – set the pressure to about 10 psi for a week. Not much foam, but not fizzy enough.

- Second attempt – crank up to 20 psi and leave for a few days. Bleed off pressure and set to about 5 psi to serve. Still not fizzy enough.

- Third attempt – Crank up the pressure past 20 psi and leave for a week. Bleed off the pressure and now I have far too much foam, with not a great deal of fizz. I did notice that the beer didn’t seem cold enough, so I set the temp to 4 degrees C, with the 2 degree tolerance.

- Forth attempt. I have cranked it right up to 40 psi and left it for 2 days. Haven’t tried it yet.

So I suppose my questions are as follows:

- Put Gas on the beer out post for carbing or just straight on the gas in? Looking at the tables for style of beer I have, pressure at 10 to 13psi looks about right for 4 degrees C. If you leave at this pressure, will you get loads of foam, given the length of beer line? If you reduce to 5psi, will the level of CO2 in the beer drop and you get flat beer?

- There are two schools of thought – 1. Set the pressure very high for a few days and bleed off, and then reduce to around 5psi for serving. 2. Set to around 10psi for two weeks, and then leave at this to serve the beer.

- Should I just take each keg out and do the rolling quick thing for now, while I get the hang of it?

- Length of beer line – Mine is 3/8 OD. I have seen equations for length / diameter and lift, but my pipes just sit on the top of the kegs. I have cut mine to 2M /6ft. Does this seem OK?

- Is the probe stuck in a pint glass of water representative of the temperature in the keg? I like my beer cold.

I have done so much research, looking at John Guest fitting, freezer sizes, wiring up a STC1000 controller and sanke couplers. I haven’t even mentioned the in/out ball locks or the stubborn centre tube and filling a Sanke keg yet.

I apologise if this has been answered on a number of occasions, but I think I have got myself very confused, reading one forum after another and watching one

Youtube video after another. Any tips would be greatly appreciated.

Thanks. David.

-

bob3000

Re: Keg Pressure / Beer Line / Force carbing question

You say the first attempt was fizzy enough but no foam? Sounds like you where almost there with that. Once you have the carbonation right you are pretty much there. If you want a little more foam, agitate the beer in the glass or turn the reg up a few psi.

40psi for 2 days is a recipe for disaster. if you over carb you will have a lot of carbonic acid and the beer will be very unpleasant.

I'd say go for the fist approach. be patient, wait at least a week, turn the psi up a little for more carbonation and foam.

40psi for 2 days is a recipe for disaster. if you over carb you will have a lot of carbonic acid and the beer will be very unpleasant.

I'd say go for the fist approach. be patient, wait at least a week, turn the psi up a little for more carbonation and foam.

-

Belter

Re: Keg Pressure / Beer Line / Force carbing question

My kegs take a minimum of 3 weeks to carb properly. I use the gas in post and set to around 10psi depending on beer style or temp it varies. My saison is up at 25psi.

I'd try and be more patient. Set to the appropriate psi for the amount of vols you want then leave until it's carbed.

I'd try and be more patient. Set to the appropriate psi for the amount of vols you want then leave until it's carbed.

Re: Keg Pressure / Beer Line / Force carbing question

I normally have good carbonation in a corny within a week. Occasionally shaking the keg for the first few days helps get the CO2 to dissolve but you'll need to leave it to settle especially if you have some sediment still in suspension.

My view is that serving pressure and carbonation pressure should be the same. You can crank up the pressure for a few hours/1 day at the start of carbonation but then dial it back to the correct pressure based on temperature and desired carbonation volume... no need to bleed off pressure. If you turn down your pressure you will slowly lose carbonation (condition). You need to have a balanced system to stop foam. That means the resistance of the serving line after the keg must balance the pressure in the keg. There are calculators online that tell you the correct tube length and diameter for your setup. Flow control taps can help but really only allow you to use differently carbonated beers not to balance a whole system.

My view is that serving pressure and carbonation pressure should be the same. You can crank up the pressure for a few hours/1 day at the start of carbonation but then dial it back to the correct pressure based on temperature and desired carbonation volume... no need to bleed off pressure. If you turn down your pressure you will slowly lose carbonation (condition). You need to have a balanced system to stop foam. That means the resistance of the serving line after the keg must balance the pressure in the keg. There are calculators online that tell you the correct tube length and diameter for your setup. Flow control taps can help but really only allow you to use differently carbonated beers not to balance a whole system.

Drinking: AG#7 Final Sprint (APA), AG#8 Buckwheat Brett (Saison - Saison/Brett), AG#9 Helles Meister

Conditioning: -

Fermenting: Selection Pinot Grigio

Planning: Orange Blossom Mead, Mexican Honey Mead, Chocolate Stout

Conditioning: -

Fermenting: Selection Pinot Grigio

Planning: Orange Blossom Mead, Mexican Honey Mead, Chocolate Stout

Re: Keg Pressure / Beer Line / Force carbing question

Amen to this. Such a waste of CO2 I've always thought.och29 wrote: My view is that serving pressure and carbonation pressure should be the same.

I went through the same debacle about a year ago - search my posts if you want to have a read.

My setup is a little different in that I keep my kegs at ambient and run the beer through an under counter (pub style) cooler. This means I need to pressurise the kegs higher to carbonate them to the same fizzyness. I have been using 30 psi over the summer with great success, in the coming weeks I will lower that significantly.

I also have about 15 ft of 3/16 beer line coiled up between my cooler and tap, to balance the system as others have touched upon. You probably won't cure your issue until you understand what causes foam. It is the change in pressure that happens at the tap, and to avoid foaming it needs to be no more than 2 psi. If your keg is at 30 psi and you have a negligible length of tubing between your keg and tap, the change in pressure is 30 psi and that will be a nightmare. As the foaming is the CO2 coming out of solution, that is why your foamy beer appeared not be fizzy. You can either lower the pressure in your kegs right down and live with less fizzy beer which doesn't foam, or add a lot of 3/16 tubing to reduce the pressure on the way to your tap. Or a mixture of the two.

As others have pointed to, the keg that is up at 40 psi I would bleed down now, otherwise you will be venting it out of solution for weeks!

Hope this helps.

Re: Keg Pressure / Beer Line / Force carbing question

As do I! Means you have to be more exacting with line balancing and understanding of how to setup kegs but works flawlessly in the end!Jambo wrote:och29 wrote: My setup is a little different in that I keep my kegs at ambient and run the beer through an under counter (pub style) cooler.

Drinking: AG#7 Final Sprint (APA), AG#8 Buckwheat Brett (Saison - Saison/Brett), AG#9 Helles Meister

Conditioning: -

Fermenting: Selection Pinot Grigio

Planning: Orange Blossom Mead, Mexican Honey Mead, Chocolate Stout

Conditioning: -

Fermenting: Selection Pinot Grigio

Planning: Orange Blossom Mead, Mexican Honey Mead, Chocolate Stout

-

dmdrabble

Re: Keg Pressure / Beer Line / Force carbing question

All,

Thanks for the great advice. Gave me some things to think about, mainly the pressure to set and beer line lengths. I can see that it makes sense that beer at pressure dispensed at atmospheric pressure will cause the CO2 to expand and cause foam.

The first thing I did was to knock back the 40psi straight away.

I've now got 30m of beer line coming in few days. I intend to divide by 3 and work back. According to the tables, my lager should be under around 14psi of pressure at 40f to have about 2.6 vol of CO2.

The beer line calculation suggests around 15ft of 3/8 od/ 1/4 Id pipe length.

After several dark nights in the garage with my torch and spilt beer, I have turned off the gas and decided to vent the PRV over the next few days, to get all the CO2 out. I think maybe I've overdone it with the pressure. I then intend to set to around 15 psi and attach my longer lines, when they arrive.

One final question if I may: before turning off the gas, I attached 4m of pipe to one of the kegs. I just got loads of foam, with flat beer. Can anyone explain why this might be happening? After venting out the CO2 I now get zero flow. I notch up a couple of psi, I get a glass full of foam.

I'm confused and my head hurts. I need a beer!

Thanks for the great advice. Gave me some things to think about, mainly the pressure to set and beer line lengths. I can see that it makes sense that beer at pressure dispensed at atmospheric pressure will cause the CO2 to expand and cause foam.

The first thing I did was to knock back the 40psi straight away.

I've now got 30m of beer line coming in few days. I intend to divide by 3 and work back. According to the tables, my lager should be under around 14psi of pressure at 40f to have about 2.6 vol of CO2.

The beer line calculation suggests around 15ft of 3/8 od/ 1/4 Id pipe length.

After several dark nights in the garage with my torch and spilt beer, I have turned off the gas and decided to vent the PRV over the next few days, to get all the CO2 out. I think maybe I've overdone it with the pressure. I then intend to set to around 15 psi and attach my longer lines, when they arrive.

One final question if I may: before turning off the gas, I attached 4m of pipe to one of the kegs. I just got loads of foam, with flat beer. Can anyone explain why this might be happening? After venting out the CO2 I now get zero flow. I notch up a couple of psi, I get a glass full of foam.

I'm confused and my head hurts. I need a beer!

Re: Keg Pressure / Beer Line / Force carbing question

Hi,

You would probably be better off using 3/16 line as you need less of it for the same pressure drop, and you'll have much less beer sitting between the keg and tap which has several advantages.

Your last question, I have seen similar before. I don't really know the answer but it may be that it hasn't reached equilibrium yet. Ie there is a lot of co2 still in solution and the 2psi on the gauge isn't a true indication of what is in solution. If you go back out and see the gauge sitting at a higher pressure this would confirm that, I think.

Good luck, it's amazing once you get it working

You would probably be better off using 3/16 line as you need less of it for the same pressure drop, and you'll have much less beer sitting between the keg and tap which has several advantages.

Your last question, I have seen similar before. I don't really know the answer but it may be that it hasn't reached equilibrium yet. Ie there is a lot of co2 still in solution and the 2psi on the gauge isn't a true indication of what is in solution. If you go back out and see the gauge sitting at a higher pressure this would confirm that, I think.

Good luck, it's amazing once you get it working

-

dmdrabble

Re: Keg Pressure / Beer Line / Force carbing question

Hello all and thanks for the replies.

I have considered all of the answers and the first thing I did was switch off the gas supply and vent off pressure everyday. I have now done this for two weeks and have zero pressure in the cornys and minimal in the sanke. I noted the length of pipe v beer line length.

In the meantime, I ordered 30 metres of 3/8OD / 1/4 Id beer line. Using the calculators, I have my CO2 set to around 13psi for the carbonation I want. With the taps being 1 -1.5 feet above the centre of the kegs, I got a figure of 19 feet. I generously cut 3 lots of 22 foot long pipes. It's all connected back on, with the pressure set to around 13ish Psi. I thought that I would draw off a quick slurp. Result: 1 full glass of foam. WTF!!

Am I being impatient again - in other words let the gas dissolve in the beer for a week? Am I starting from scratch in theory? I suppose you wouldn't draw off a pint the same day you put your gas in the beer would you?

The whole thing has got me doubting myself and I can't think straight. The beer tastes great, but flat - after the foam dies down. I was hoping to have house warming soon and show off the beer taps, but I may as we'll give them a bloody chocolate flake with the glass of foam!

Ps. I noted the smaller diameter pipe comment, but had already clicked buy now on eBay at that point. Maybe I should consider smaller pipes??? This would mean that I would have to throw out my John Guest fitting that I have bought.

Good news. I have nailed the mash tun cooler box conundrum I had. The tank connector was too short and I couldn't fit a pipe on. Managed to get all the parts after some serious research. I will have to post it with pictures on here!

This home brew thing don't half throw up some challenges!

I have considered all of the answers and the first thing I did was switch off the gas supply and vent off pressure everyday. I have now done this for two weeks and have zero pressure in the cornys and minimal in the sanke. I noted the length of pipe v beer line length.

In the meantime, I ordered 30 metres of 3/8OD / 1/4 Id beer line. Using the calculators, I have my CO2 set to around 13psi for the carbonation I want. With the taps being 1 -1.5 feet above the centre of the kegs, I got a figure of 19 feet. I generously cut 3 lots of 22 foot long pipes. It's all connected back on, with the pressure set to around 13ish Psi. I thought that I would draw off a quick slurp. Result: 1 full glass of foam. WTF!!

Am I being impatient again - in other words let the gas dissolve in the beer for a week? Am I starting from scratch in theory? I suppose you wouldn't draw off a pint the same day you put your gas in the beer would you?

The whole thing has got me doubting myself and I can't think straight. The beer tastes great, but flat - after the foam dies down. I was hoping to have house warming soon and show off the beer taps, but I may as we'll give them a bloody chocolate flake with the glass of foam!

Ps. I noted the smaller diameter pipe comment, but had already clicked buy now on eBay at that point. Maybe I should consider smaller pipes??? This would mean that I would have to throw out my John Guest fitting that I have bought.

Good news. I have nailed the mash tun cooler box conundrum I had. The tank connector was too short and I couldn't fit a pipe on. Managed to get all the parts after some serious research. I will have to post it with pictures on here!

This home brew thing don't half throw up some challenges!

Re: Keg Pressure / Beer Line / Force carbing question

3 lots of 22 ft = 66ft or am I misreading this?

Unless anyone has any other suggestions, I'd bite the bullet and get 3/16 pipe, it's the only way I got mine sorted.

Unless anyone has any other suggestions, I'd bite the bullet and get 3/16 pipe, it's the only way I got mine sorted.

Re: Keg Pressure / Beer Line / Force carbing question

Ah I see - 3 kegs, 22 ft each. Maybe leave it a few days to settle and then see what you get. I think ultimately if you want lively carbonation you will need to get small tubing but might as well make sure you've got it at a steady state first

Re: Keg Pressure / Beer Line / Force carbing question

I've got around 5m of 5/16 in between 2 bits of 3/8 from a sankey, the beer is carbonated to 1.5 vols, pressure is a constant 5psi @ 11°C I get a perfect pour with a small amount of small bubbles rising and a head that stays to the bottom of the glass. I probably don't need 5m of 3/16 but I'm loathe to cut it down just yet.

I've had all sorts of problems before I got a keezer and line sorted, it was ht and miss with fluctuating temperatures, it's difficult to get the CO2 out of an over carbonated beer, it can take weeks and by that time you've almost drunk it all, best to start low and build it up over a couple of weeks to the level you need, just takes practice to get it dialled in.

I've had all sorts of problems before I got a keezer and line sorted, it was ht and miss with fluctuating temperatures, it's difficult to get the CO2 out of an over carbonated beer, it can take weeks and by that time you've almost drunk it all, best to start low and build it up over a couple of weeks to the level you need, just takes practice to get it dialled in.

-

Fil

- Telling imaginary friend stories

- Posts: 5229

- Joined: Sun Oct 16, 2011 1:49 pm

- Location: Cowley, Oxford

Re: Keg Pressure / Beer Line / Force carbing question

ive lost the link so am relying on hazy recall, but the essence of serving a good pint is balancing the keg pressure set to maintain condition and serve with restriction along the serving line so that at the tap the pressure drop or gradient at release is mot huge, its a dramatic change in state that can stimulate a foam out.

the 3/16" line will restrict the pressure at a rate between 1 and 2 psi for each foot length most folk find a length 4-6ft sorts them out. the other benefit of the micro line is it isnt holding a large volume of liquid, the further from the keg along the line you go the pressure in the line drops and the co2 is released resulting in gas pockets that cause the tap to cough and splutter at the start of a serving session.

with 22 ft of 3/8" line you may be chucking away a fair volume of beer as spit from the start of each session, with the microline (3/16") your talking about 1/4 a pint of froth coughed up at the start of a serving session which if left to settle is only a few mm of liquid depth in pint glass..

the 3/16" line will restrict the pressure at a rate between 1 and 2 psi for each foot length most folk find a length 4-6ft sorts them out. the other benefit of the micro line is it isnt holding a large volume of liquid, the further from the keg along the line you go the pressure in the line drops and the co2 is released resulting in gas pockets that cause the tap to cough and splutter at the start of a serving session.

with 22 ft of 3/8" line you may be chucking away a fair volume of beer as spit from the start of each session, with the microline (3/16") your talking about 1/4 a pint of froth coughed up at the start of a serving session which if left to settle is only a few mm of liquid depth in pint glass..

ist update for months n months..

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

-

NobbyIPA

Re: Keg Pressure / Beer Line / Force carbing question

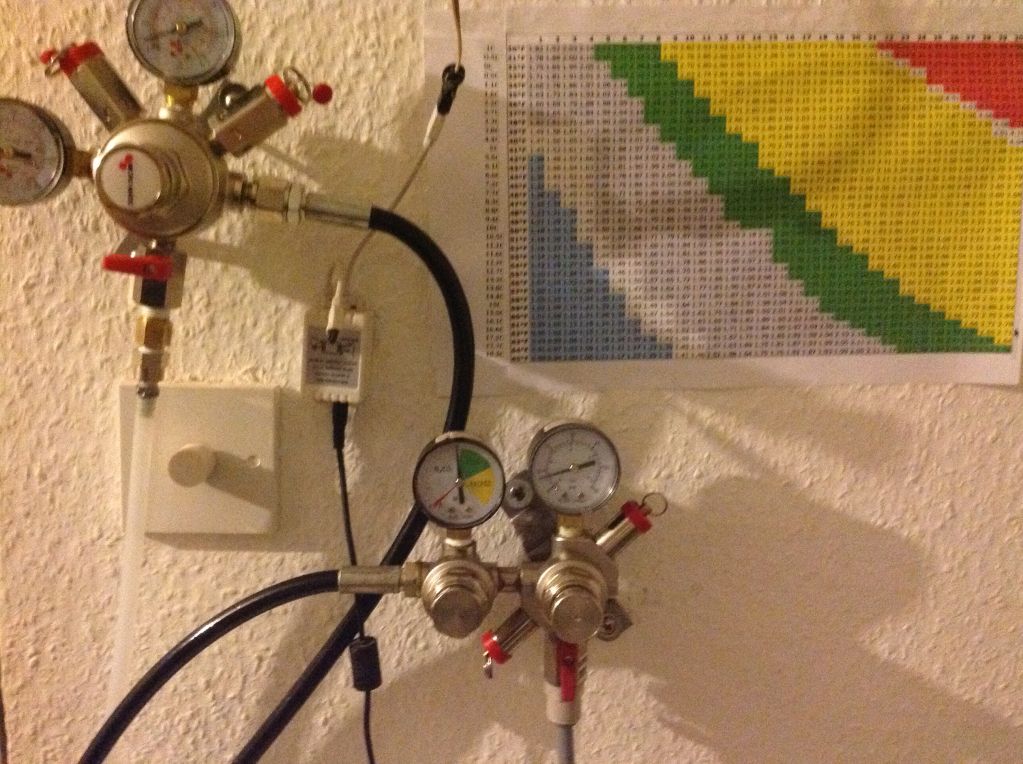

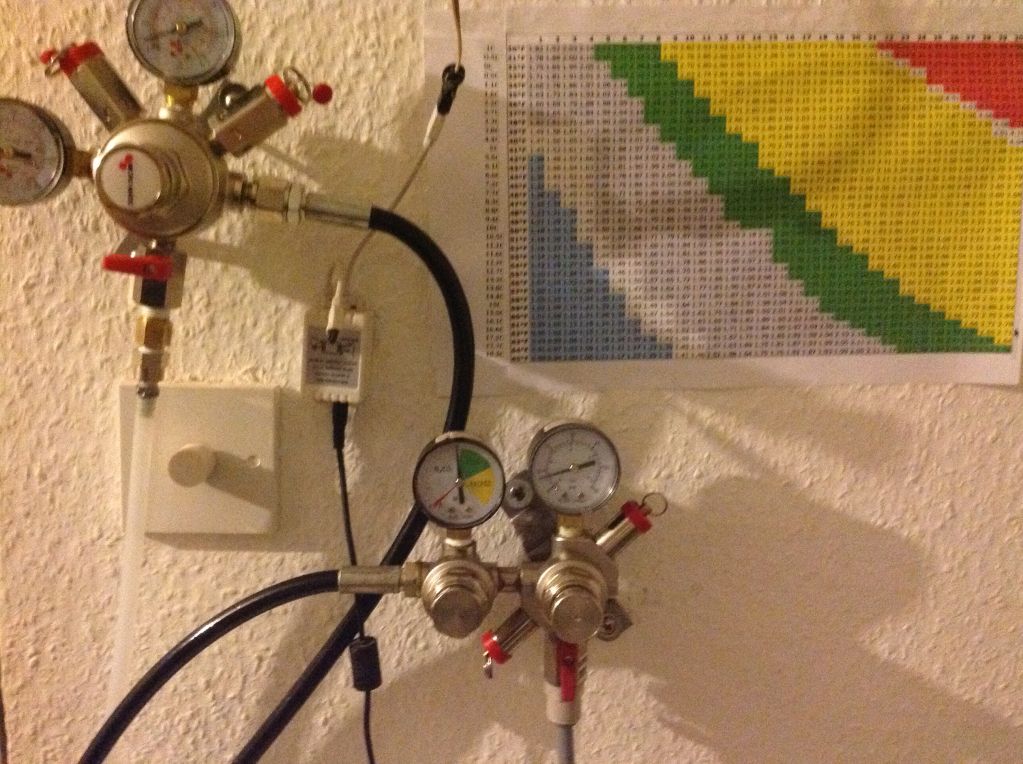

hers how mine works

2nd time successful with me gas set up

8c at 12psi for 10 days pure co2

3/16 beer line 5ft long

no rolling the keg for me

i use this chart

http://www.kegerators.com/carbonation-table.php

which i have added centigrade to

then change over to n2 /co2 70-30

serving at 22psi with co2/n2

10 psi if pure co2

as said i have been lucky i suppose both brews have woked out looking like this

3/16 line i reckon is better i have tried 3/8 but the results were not as good for me anyway

2nd time successful with me gas set up

8c at 12psi for 10 days pure co2

3/16 beer line 5ft long

no rolling the keg for me

i use this chart

http://www.kegerators.com/carbonation-table.php

which i have added centigrade to

then change over to n2 /co2 70-30

serving at 22psi with co2/n2

10 psi if pure co2

as said i have been lucky i suppose both brews have woked out looking like this

3/16 line i reckon is better i have tried 3/8 but the results were not as good for me anyway

-

dmdrabble

Re: Keg Pressure / Beer Line / Force carbing question

Well thanks all for your great advice. Sorry for late response, but I've been away.

Anyhow, took the advice about the 3/16 pipe and ordered 10 metres of the stuff. Difference is remarkable. So simple, but I guess when you know the answers and have the benefit of experience. I've even cranked up the pressure and am now drinking a lovely fruity wheat beer in an Erdinger glass with that lovely foam on top and lots of bubbles. One happy man. Learned a lot about pressures and beer lines to pass into my friend at work when he decides to step up!

Looking forward to the Christmas parties.

In the spirit of sharing, I'm going to create a post about a cooler box mash tun and post on here. I know it's been done to death all over youtube, but they all tend to be american with links to Home Depot et where you find it difficult to source parts.. I've got pictures of my kit with Uk suppliers and part number for all you need to make the manifold and ball valve, tank connectors and parts etc.

Anyhow, onto all grain now. What a great hobby we have, getting to drink what we make. Cheers!

David.

Anyhow, took the advice about the 3/16 pipe and ordered 10 metres of the stuff. Difference is remarkable. So simple, but I guess when you know the answers and have the benefit of experience. I've even cranked up the pressure and am now drinking a lovely fruity wheat beer in an Erdinger glass with that lovely foam on top and lots of bubbles. One happy man. Learned a lot about pressures and beer lines to pass into my friend at work when he decides to step up!

Looking forward to the Christmas parties.

In the spirit of sharing, I'm going to create a post about a cooler box mash tun and post on here. I know it's been done to death all over youtube, but they all tend to be american with links to Home Depot et where you find it difficult to source parts.. I've got pictures of my kit with Uk suppliers and part number for all you need to make the manifold and ball valve, tank connectors and parts etc.

Anyhow, onto all grain now. What a great hobby we have, getting to drink what we make. Cheers!

David.