AG#052 - Channel Hopper

-

coatesg

Re: AG#052 - Channel Hopper

Good info there Si - and that sticky mess from Hop Back looks familiar  Interesting what Steve says about breweries spraying wort back over the top of the yeast - convention is to not aerate the wort once started, but I guess if the yeast is good at mopping up oxygen, then you shouldn't get the bad oxidation effects?

Interesting what Steve says about breweries spraying wort back over the top of the yeast - convention is to not aerate the wort once started, but I guess if the yeast is good at mopping up oxygen, then you shouldn't get the bad oxidation effects?

-

SiHoltye

Re: AG#052 - Channel Hopper

I think during the early part of fermentation O2 is beneficial to the growth phase of the yeast. At this time the yeast uses up the O2 quickly and so it isn't left to oxidise your beer. After this growth phase added O2 remains in the beer and oxidisation occurs.

Yeast strains are different though, I'm talking about a brewery yeast really. I think S04 is pants at mopping up O2 so wouldn't re-aerate that, or any other dried yeast really - they're prepared with in-built O2 reserves so as long as you pitch enough yeast you shouldn't need to introduce anymore air/O2 after the initial aeration prior to pitching..

Is that right? It's a good guess and sounds convincing

Yeast strains are different though, I'm talking about a brewery yeast really. I think S04 is pants at mopping up O2 so wouldn't re-aerate that, or any other dried yeast really - they're prepared with in-built O2 reserves so as long as you pitch enough yeast you shouldn't need to introduce anymore air/O2 after the initial aeration prior to pitching..

Is that right? It's a good guess and sounds convincing

-

RabMaxwell

Re: AG#052 - Channel Hopper

I will need to set-up an aeration stone plugged into an electric socket timer when i brew again at the weekend .Cheers for the infoSiHoltye wrote:Yep.

-

SiHoltye

Re: AG#052 - Channel Hopper

That should help the reproduction of yeast in your wort, though I think the issue I'm looking at in mine is with the top fermenting nature (floating yeast). When I draw a sample from the tap (day 3) the sample is very clear and not yeast laden like when using bottom fermenting yeasts. It seems like early flocculation upside down. All the damn yeast is sitting like a pie crust on top of the beer!  I want it dispersed for longer to chew the sugars throughout my bucket rather than nibbling at the top layer.

I want it dispersed for longer to chew the sugars throughout my bucket rather than nibbling at the top layer.

Don't get me wrong it is fermenting, (now 1.017) the situation feels like WLP005 in reverse whereby you rouse that up 'cos it settles out too quick, this needs rousing down (if that's linguistically possible!)

whereby you rouse that up 'cos it settles out too quick, this needs rousing down (if that's linguistically possible!)

Adding a note in my brewing software that this yeast benefits from twice daily rousings for 3 days. I won't re-aerate 'cos I think I've pitched enough yeast, it's just where it is

Sample tastes luvverly though Rab, good luck with yours, I'm doing a SL clone with the slurry next - yum.

Don't get me wrong it is fermenting, (now 1.017) the situation feels like WLP005 in reverse

Adding a note in my brewing software that this yeast benefits from twice daily rousings for 3 days. I won't re-aerate 'cos I think I've pitched enough yeast, it's just where it is

Sample tastes luvverly though Rab, good luck with yours, I'm doing a SL clone with the slurry next - yum.

-

RabMaxwell

Re: AG#052 - Channel Hopper

Hello SiHoltye i am getting the opposite of you i think so far i have it in my yeast propagator making slurry for my 120 litre brew at the weekend.

( Yeast Propagator )

I took a sample this morning so i can take a hydrometer reading but the sample was no use as it's almost all yeast slurry it's taking it from about 2 inches off the bottom mine is also (Day 3 ).As for that slimy looking yeast head it looks very similar to WL Edinburgh Ale Yeast.

( Yeast Propagator )

I took a sample this morning so i can take a hydrometer reading but the sample was no use as it's almost all yeast slurry it's taking it from about 2 inches off the bottom mine is also (Day 3 ).As for that slimy looking yeast head it looks very similar to WL Edinburgh Ale Yeast.

-

Chappie519

Re: AG#052 - Channel Hopper

Hi Rab

On that yeast propogation setup - do you just pump air in contantly or how does it work?

Sorry to hi-jack the thread guys.

On that yeast propogation setup - do you just pump air in contantly or how does it work?

Sorry to hi-jack the thread guys.

-

RabMaxwell

Re: AG#052 - Channel Hopper

I use a stir-plate to grow the yeast first then pitch the yeast into the king keg & treat it like a normal fermentation.The king keg is also temperature controlled by a Maxi 310 cooler /heat exchanger/light bulb & an ATC 800.If i aerate the Hop-Back yeast next time i will probably attach the filtered air tube to the out-tap & let it bubble from the bottom up through the beer & exit through the blow-off tube.

-

SiHoltye

Re: AG#052 - Channel Hopper

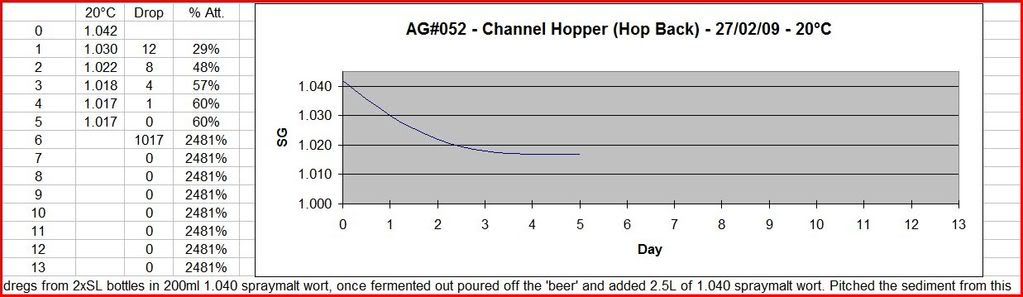

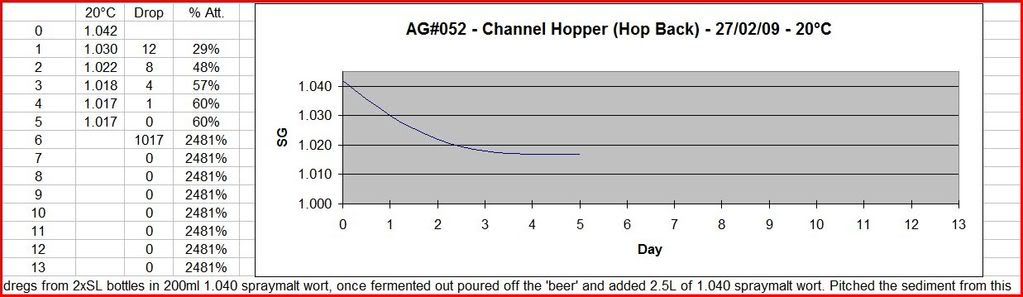

Ar5e, ar5e, ar5e, ar5e. Damn thing has stuck at 1.017.

Summer Lightning has has attenuation of 77-78%, I've got a poxy 60%. I'm thinking that rousing in the first 2 days might be very important for this yeast, to keep more yeast suspended whilst it's working at it's hardest. It makes me wonder whether to use the slurry in the next brew (a SL clone) or to change brew and more reliably produce better end result. 'Spose perseverance would be better to find out if different handling improves things, it's just a nuisance after a full brewday to produce beer not how you wanted it

Summer Lightning has has attenuation of 77-78%, I've got a poxy 60%. I'm thinking that rousing in the first 2 days might be very important for this yeast, to keep more yeast suspended whilst it's working at it's hardest. It makes me wonder whether to use the slurry in the next brew (a SL clone) or to change brew and more reliably produce better end result. 'Spose perseverance would be better to find out if different handling improves things, it's just a nuisance after a full brewday to produce beer not how you wanted it

-

RabMaxwell

Re: AG#052 - Channel Hopper

SiHoltye i will give this a go on saturday if it works for steve at the brewery it must be ok.SiHoltye wrote:Just spoke to Steve at the brewery, he said that after pitching at not a particularly high rate they pump in sterile air (not O2) in to the fermentor for 20 mins of every hour for the first 12 hours, then let it rest for 12hrs. Then they do the same 4 times more - 20 mins in hour for the next 4 hours. After 48hrs he'd expect a 1.040 wort to have attenuated to 1.014.

He emphasised the importance of oxygen to their yeast during fermentation.

-

SiHoltye

Re: AG#052 - Channel Hopper

Been thinking about how to add a lot of air early in the ferment, without buying pumps/gas equipment/air filters and needing to 'mother' the brew by returning to it every few hours, so think I might drop the next brew 24hrs after pitching into another fermentor splash aerating as I do.

My thinking is that it'll be early on enough for the yeast to use up the added air so no oxidation problem later on. I've heard that dropping later on into the ferment people have experienced stuck fermentations, but am hopeful that by transferring all the yeast and at a time when it'll be going bonkers activity-wise it should have the desired effect of introducing O2 for the yeast to use and it will redistibute the yeast throughout the beer. Brewery yeasts sound more tolerant of this sort of action than dried yeasts who should have sufficient reserves of O2 anyway.

Has anybody dropped a brewery yeast beer early in the ferment before? (On our homebrew scale I mean - anticipating smart Alec comments )

)

My thinking is that it'll be early on enough for the yeast to use up the added air so no oxidation problem later on. I've heard that dropping later on into the ferment people have experienced stuck fermentations, but am hopeful that by transferring all the yeast and at a time when it'll be going bonkers activity-wise it should have the desired effect of introducing O2 for the yeast to use and it will redistibute the yeast throughout the beer. Brewery yeasts sound more tolerant of this sort of action than dried yeasts who should have sufficient reserves of O2 anyway.

Has anybody dropped a brewery yeast beer early in the ferment before? (On our homebrew scale I mean - anticipating smart Alec comments

-

SiHoltye

Re: AG#052 - Channel Hopper

Read this info on the always 100% accurate home of 'take-it-to-the-bank' sage wisdom Wikipaedia  It's right this time I think though

It's right this time I think though  My thought's in red.

My thought's in red.

Double dropping, more commonly known as the dropping system is a brewing method for the production of ales. During the early 20th century it was the most popular method of fermentation for English ales (English Ales - good). It is less commonly used today as it requires additional brewing vessels and a 2-tier brewhouse. Also, other brewing methods can now emulate these beers without using this brewing method (this could be the recirculation by pumps that many breweries use now).

During the double dropping process the wort (newly brewed, fermenting beer) is first fermented for a period of time before being 'dropped', under gravity or by other means, into a lower vessel where it continues fermentation. Brakspear's beers are 'dropped' the morning after the day they were brewed - typically about 16 hours later (a bit earlier than the arbitrary 24 I mentioned so I'll drop nearer this). This process originally took place at the original Brakspear's brewhouse in Henley. Some time later, Brakspear's brewing then moved to Refresh UK's brewery in Whitney. A new Brakspear's brewhouse was built to include the original double dropping system.

The dropping process has two primary effects on the beer being fermented. In 'dropping' the newly fermenting beer, 'trub' (dead yeast and excess, staling and haze-forming protein from the malted barley) that has settled during the first period of fermentation will be left behind (not in mine it won't 'cos a) I don't feel there is enough to worry about, and b) I want to be certain of transferring all the yeast so will pour/tip the whole lot), leaving a cleaner beer and a cleaner yeast to crop from the beer for the next fermentation.

The second effect of the dropping process is the aeration of the wort, which results in healthy clean yeast growth (woohoo that's what I'm talking about!), and in certain circumstances produces more complex flavors. Brakspear attributes that some of the flavor common to its beers is due to a combination of its very old complex multi-strain yeast and the dropping method which encourages it to produce the butterscotch-flavored compound diacetyl (yeast specific characteristic).

I'm encouraged that I'm using the right 'type' of yeast (brewery environment aclimbatized), and that I'm going to do it at the right stage of fermentation for this technique to benefit me. All that remains is for me to do this and swear about it when it sticks

Going to corni this one week primary Channel Hopper brew tomorrow night for the Summer Lightning brewday on Friday, dropping Saturday...ooer

Double dropping, more commonly known as the dropping system is a brewing method for the production of ales. During the early 20th century it was the most popular method of fermentation for English ales (English Ales - good). It is less commonly used today as it requires additional brewing vessels and a 2-tier brewhouse. Also, other brewing methods can now emulate these beers without using this brewing method (this could be the recirculation by pumps that many breweries use now).

During the double dropping process the wort (newly brewed, fermenting beer) is first fermented for a period of time before being 'dropped', under gravity or by other means, into a lower vessel where it continues fermentation. Brakspear's beers are 'dropped' the morning after the day they were brewed - typically about 16 hours later (a bit earlier than the arbitrary 24 I mentioned so I'll drop nearer this). This process originally took place at the original Brakspear's brewhouse in Henley. Some time later, Brakspear's brewing then moved to Refresh UK's brewery in Whitney. A new Brakspear's brewhouse was built to include the original double dropping system.

The dropping process has two primary effects on the beer being fermented. In 'dropping' the newly fermenting beer, 'trub' (dead yeast and excess, staling and haze-forming protein from the malted barley) that has settled during the first period of fermentation will be left behind (not in mine it won't 'cos a) I don't feel there is enough to worry about, and b) I want to be certain of transferring all the yeast so will pour/tip the whole lot), leaving a cleaner beer and a cleaner yeast to crop from the beer for the next fermentation.

The second effect of the dropping process is the aeration of the wort, which results in healthy clean yeast growth (woohoo that's what I'm talking about!), and in certain circumstances produces more complex flavors. Brakspear attributes that some of the flavor common to its beers is due to a combination of its very old complex multi-strain yeast and the dropping method which encourages it to produce the butterscotch-flavored compound diacetyl (yeast specific characteristic).

I'm encouraged that I'm using the right 'type' of yeast (brewery environment aclimbatized), and that I'm going to do it at the right stage of fermentation for this technique to benefit me. All that remains is for me to do this and swear about it when it sticks

Going to corni this one week primary Channel Hopper brew tomorrow night for the Summer Lightning brewday on Friday, dropping Saturday...ooer

-

SiHoltye

Re: AG#052 - Channel Hopper

It's dropped to 1.016 now, I'll corni it tomorrow night, purge the head space and keep it at fermenting temps venting ocassionally for a few days more. This will get it out of the way for the next brew and let it keep fermenting slowly if it wants.

-

coatesg

Re: AG#052 - Channel Hopper

Surprised it's only got to 1.016 - though I guess your mash temp was reasonably high so there'll be a good bit of residual unfermentables I guess. Let us know how it turns out!SiHoltye wrote:It's dropped to 1.016 now, I'll corni it tomorrow night, purge the head space and keep it at fermenting temps venting ocassionally for a few days more. This will get it out of the way for the next brew and let it keep fermenting slowly if it wants.

-

SiHoltye

Re: AG#052 - Channel Hopper

I might have thought the higher mash temp would finish the beer at 1.012 or 1.013 all things being well. I'll report back on it.

-

Chappie519

Re: AG#052 - Channel Hopper

Higher mash temps = Less fermentables = more mouthfeelSiHoltye wrote:I might have thought the higher mash temp would finish the beer at 1.012 or 1.013 all things being well. I'll report back on it.