The forum for discussing all kinds of brewing paraphernalia.

-

Vossy1

Post

by Vossy1 » Fri Aug 18, 2006 8:17 pm

Just stuck saw blades tomorow

-

Andy

- Virtually comatose but still standing

- Posts: 8716

- Joined: Fri Nov 18, 2005 1:00 pm

- Location: Ash, Surrey

-

Contact:

Post

by Andy » Sat Aug 19, 2006 2:16 pm

Hey that was hard work!

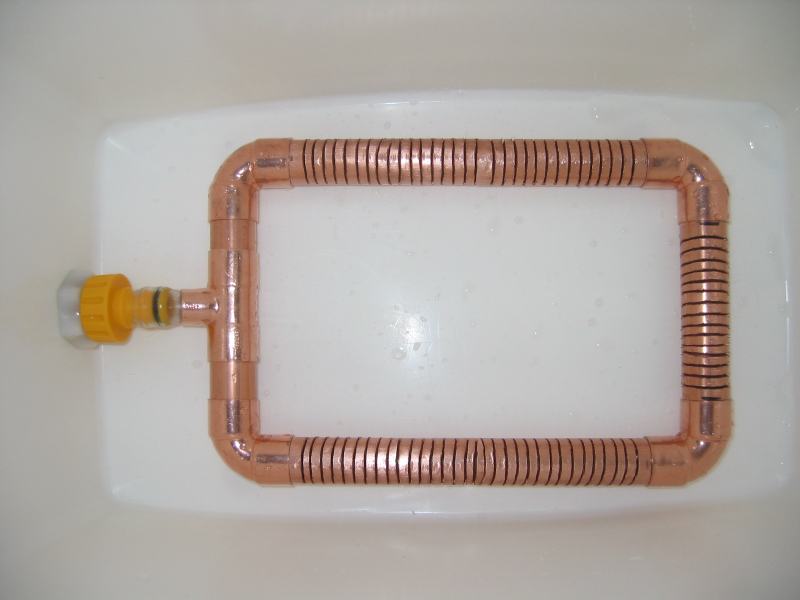

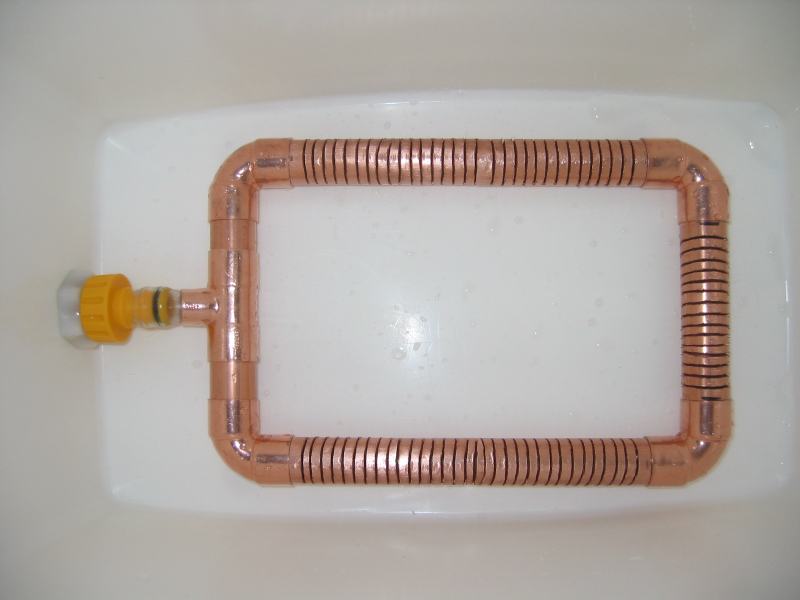

Shown slots face up for illustration only

Just done a quick test and gets a great flow! Left with 350ml of liquid in the tun when the syphon effect stops.

I don't want to see another hacksaw for some time

-

Andy

- Virtually comatose but still standing

- Posts: 8716

- Joined: Fri Nov 18, 2005 1:00 pm

- Location: Ash, Surrey

-

Contact:

Post

by Andy » Sat Aug 19, 2006 4:20 pm

QUOTE (Daft as a Brush @ Aug 19 2006, 02:46 PM) Not going to put a few slots either side of the tee then ?

At least you wont have to make another one for quite some time if ever! B)

As it's you DaaB I've added some B)

-

PieOPah

Post

by PieOPah » Sat Aug 19, 2006 4:36 pm

QUOTE (andy @ Aug 19 2006, 04:20 PM) QUOTE (Daft as a Brush @ Aug 19 2006, 02:46 PM) Not going to put a few slots either side of the tee then ?ÂÂ

ÂÂ

At least you wont have to make another one for quite some time if ever! B)

As it's you DaaB I've added some B)

ROFL

-

Bigster

Post

by Bigster » Sat Aug 19, 2006 8:23 pm

Andy

If you get a stuck mash with that 22mm stuff I will come round and sort it out myself

Nice work

-

Vossy1

Post

by Vossy1 » Sat Aug 19, 2006 8:34 pm

Very nice andy....its lovely and shiny

-

Andy

- Virtually comatose but still standing

- Posts: 8716

- Joined: Fri Nov 18, 2005 1:00 pm

- Location: Ash, Surrey

-

Contact:

Post

by Andy » Sat Aug 19, 2006 8:45 pm

How much tidy up work did you guys do on your manifolds after cutting ? The inside of the tubes are obviously very rough where the cuts have been made, did anyone file this stuff out or did you just leave it be ?

-

BlightyBrewer

Post

by BlightyBrewer » Sat Aug 19, 2006 8:50 pm

I de-burred on the inside as much as I could with a needle file.

-

Bigster

Post

by Bigster » Sat Aug 19, 2006 8:54 pm

I lost interest after trying to push tissue paper through with a screwdriver :stun Havent poisoned anyone yet .....

-

Road Runner

Post

by Road Runner » Sun Aug 20, 2006 11:54 am

I fitted mine to the tap exactly as Andy has done. Sweated a piece of poly tubing over the Hozelock fitting & it was a fairly tight push into the 22-15mm reducer T.

I also debured the insides of the copper pipe by running a half round file through them.

Unfortunately Andy, you may need the assistance of your favourite hacksaw blades again, to then clean out the slots.

-

Road Runner

Post

by Road Runner » Sun Aug 20, 2006 8:00 pm

Yep, I've done exactly as Andy, as I say. Pushed it inside the copper T as in the pic.

So far, no probs with this & not had any stray grain getting through.

The copper manifold is made big enough so that it almost reaches the far end of the cool box. But stops short of the end by about 1/2 inch. This will not allow the manifold to slide off the poly tubing when in use, the tubing is pushed a fair way into the manifold T also.

-

Andy

- Virtually comatose but still standing

- Posts: 8716

- Joined: Fri Nov 18, 2005 1:00 pm

- Location: Ash, Surrey

-

Contact:

Post

by Andy » Sun Aug 20, 2006 9:37 pm

Mine's much more shiney!

-

Vossy1

Post

by Vossy1 » Sun Aug 20, 2006 10:27 pm

-

Road Runner

Post

by Road Runner » Sun Aug 20, 2006 11:43 pm

QUOTE (andy @ Aug 20 2006, 09:37 PM) Mine's much more shiney!

Only coz it's still a virgin.

-

Vossy1

Post

by Vossy1 » Mon Aug 21, 2006 10:06 am

RR, We better be careful, we might get moderated

now Andy's passed to the dark side