Hi,

The chiller is 25m of 10mm copper - I took the muscle car approach to sizing it.

The copper is a 50 litre sankey keg. I'm using another one as my mash tun. I have a Willis immersion heater as my RIMS heater with a PID controller.

I'm going to use the Willis - via switching through a couple of ball valves - as an "instant" hot water system (under PID) to supply any needed sparge water, but I reckon that with a RIMS not much sparging is necessary given the solubility of sugars and the volume of strike water possible. If I'm wrong, then I can always partigyle, or add a hot water tank. So this is a two vessel system at present! I've made the standard sort of return manifold for the wort circulation.

I have made a reasonable false bottom from a piece of perforated 316 stainless from E-bay, which I was going to have cut with a water jet, but the job stood in a workshop for 3 months, so i took it home and cut it with an angle grinder in 1/2 an hour and three discs.

I'm going to use propane to boil my wort, and then cool via my chiller, and recirculating the cooling wort to speed the heat exchange.

I have a March May pump.

The whole lot will be fermented in a temerature controlled cabinet using an acquarium/vivarium hot/cold controller ( Not PID) in yet another 50 litre sankey keg. Dispensing will be via Sankey and Corny kegs

The whole lot will be connected with 1" Triclover clamps and copper and silicone tubing/pipe. I got a load of Triclovers and fittings from China at a good price - they are 304 Stainless, which is what the Sankeys are made from, I believe.

The good thing about the Triclover stuff is that I can experiment with configurations, and it is great to clean. For instance, I plan to use a 25Cm length of 2" ss tube with tricovers stuffed at the outflow end with a stainless steel scourer as a hop back of sorts in the recirculation circuit as I cool the wort for an IPA I have planned in my head..

HOpefully I will run the system in anger next weekend - it all seems to fit together, although I haven't got enough ball valves yet - I have three on back order at BES - nor have I finished my fermentation cabinet, but I reckon the weather and my garage are OK temp wise. It will come into it's own if I want to lager, for instance.

It may not look pretty, but it should work!

Now to try and put up some pics just with the links ...... It may go wrong here, folks!. Photobucket seems slow!

Mash tun - 50 litre keg with central drain to Triclover fitting

Lid made from itself - I did not heed the warning!

Internal view showing central outlet

From underneath

Willis 3Kw heater with Triclovers and ball valve

My favoured PID controller - it's a long story!

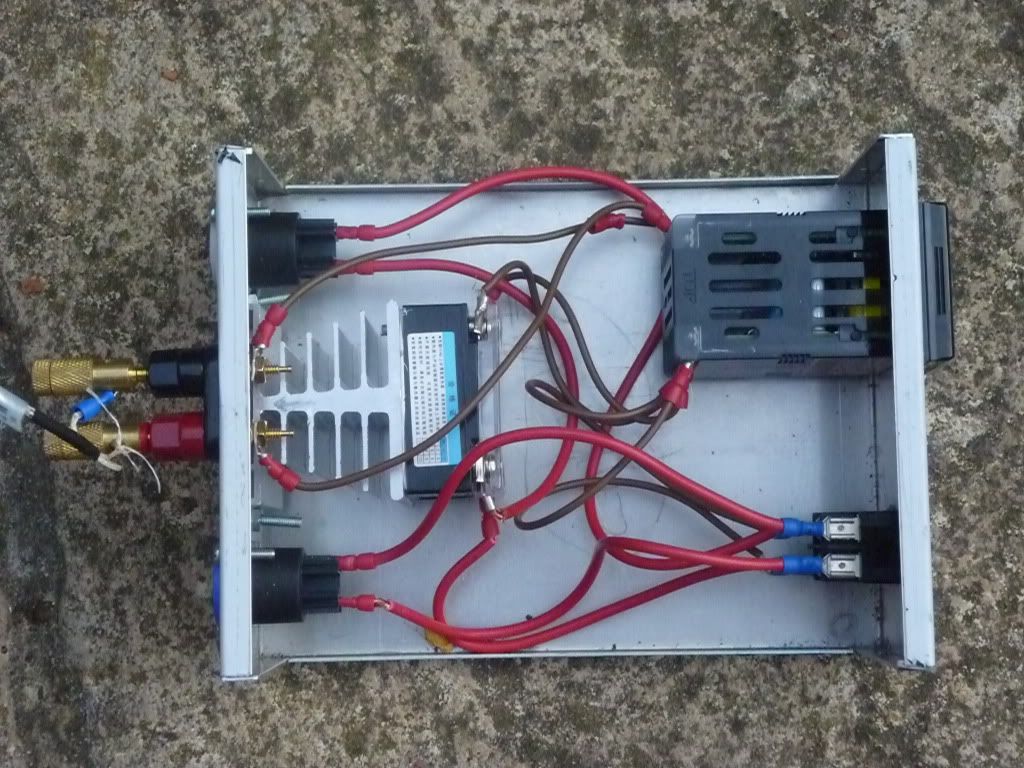

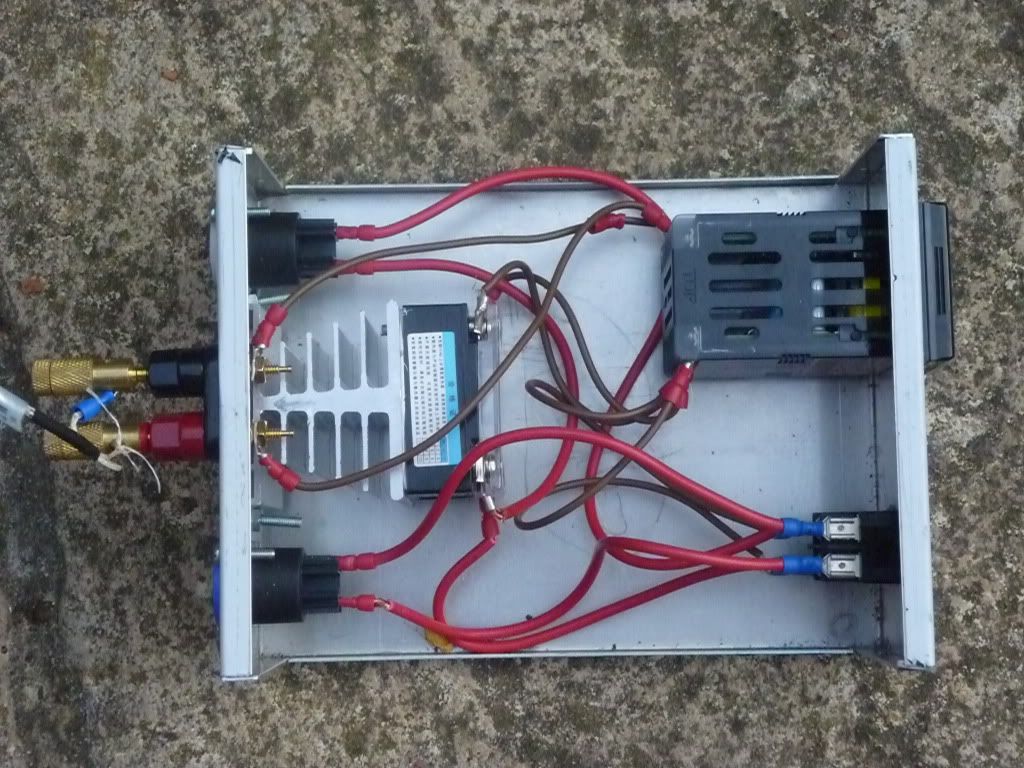

Innards of my home made PID controller

back of my PID showing 16Amp Powercon connector

Wort recirculation Manifold

March May pump triclovered up and ready to go!