I went for a 25L batch so scaled up the grain bill accordingly

OG - 1060 FG - 1012 (tbc)

Pale Ale malt - 5080g

Munich malt - 1016g

Caramalt - 271g

Wheat malt - 271g

Carahell - 136g

Chinook - 30g

Cascade - 20g 15mins

Centennial - 20g 15mins

Amarillo - 20g 15 mins

Cascade - 20g 5mins

Centennial - 20g 5mins

Amarillo - 20g 5 mins

Cascade - 20g 0mins

Centennial - 20g 0mins

Amarillo - 20g 0mins

Irish Moss - 3g 15mins

Safale US05 yeast

Method:

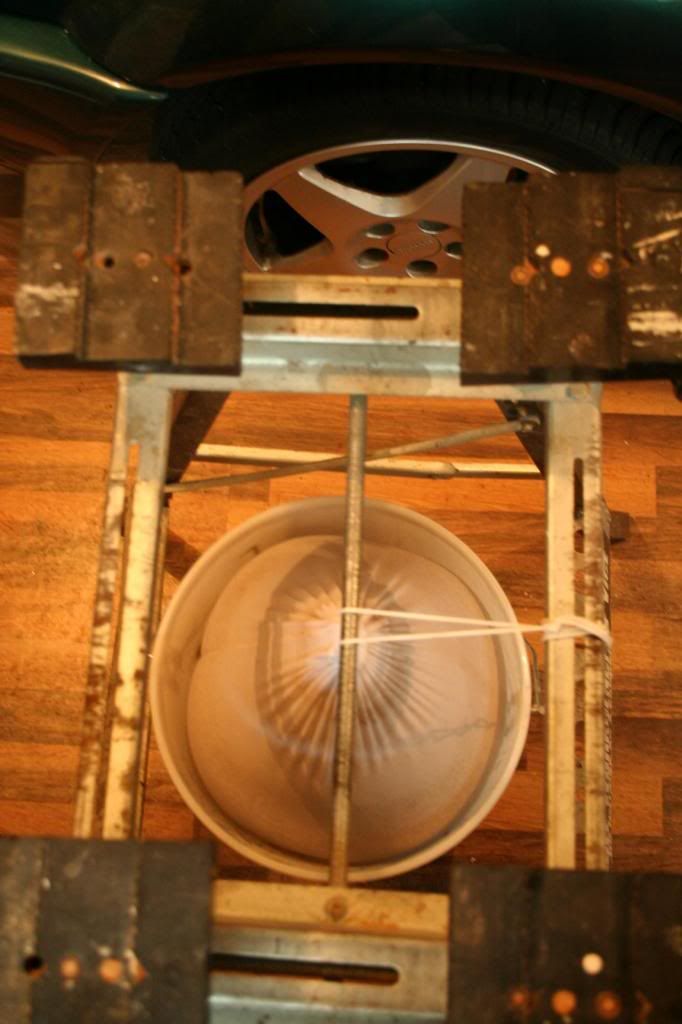

I started with 38 litres of water, boiled for 30 minutes the night before then heated back up to 66 degrees. As it was such a big grain bill I had to stick it in a FV.

I put the grain in and checked the temperature, I was aiming to keep it at 66.

Grains in.... that smells great! Never tire of that aroma!

Insulate and leave for 90 minutes to mash:

I did give it a stir and check the temperature half way through and it seemed to stay around the 66 mark:

The bag was taken out and drained. I normally tip about 3 litres of the liquid from the urn through the bag to collect in the FV below, which gets tipped back in to the urn.

Then with the temperature raised to 78 I put the grain bag back into the liquid for 30 minutes.

After the bag is drained and squeezed to get the liquid out, the 3 stages of hops are weighed out.... they smell unreal

I use a hop sock at the moment to stop the tap getting blocked up, but might get a hop strainer soon. Then it's a rolling boil for 90 mins with the first batch of hops.

Fifteen minutes to go and it's Irish Moss, the next batch of hops and the copper wort chiller submerged in the liquid to boil for the last stage.

Then the last batch of hops are added, and the wort chiller is used. It normally takes about 30 minutes to get the temperature down to 25 degrees. Then I transfer it to the FV.

I was aiming for 25 litres, but due to the larger amount of grain and hops I think more liquid was absorbed leaving me with about 23.5 to 24 litres. I couldn't fit any more liquid of grain in the urn to start with anyway!

Check the gravity at 20 degrees and it's 1060 as planned

Yeast was then pitched and then the FV was stuck in the utility room next to the boiler to hopefully keep it at a steady temperature.

Now the long wait... I will let you know how it tastes. If it tastes as good as it smells and looks then it will be a definite winner!