Looking at 20L at 1.049 and 23IBU Guessing at 77% efficiency

3000g Wheat Malt

2000g Weyermann Floor malted Czech Malt

Mash using a modified Hochkurz Schedule (45C for 45 minutes, 63C for 35Minutes, 71C for 45 Minutes, Mash out at 72C for 10 minutes)

Sparge with 6L in my case I'm going to drain and decoct the grain then strain it into the boiler.

Boil 31L for 80 minutes adding

50g Hallertau Mittelfruh at 60 minutes to go.

I'll ferment a 1L starter, using the shaken not stirred method, of WLP380 at 18C Really hoping to get spicy Clove and keep the banana in check.

This is the starter preparation, 100g spray malt in 1000g of water. Autoclaved at 121C for 15 minutes

A picture of a well aerated starter . . . Using the Martini method "shaken, not stirred"

First Job this morning was to crush the grain, so out came the Barleycrusher

Handful of grain to check the crush

Followed by the 3Kg of wheat malt

And the remainder of the 2Kg of Bohemian Pilsner malt

In the meantime 23L of water was going into the BM. I dropped the alkalinity from a (measured) 53mg/L down to 14 (measured), with sulphuric acid, as this was a 'pale' beer. The TDS of 102 showed me that my water was probably very close to my last profile reading at the end of June. I would have preferred to use hydrochloric, but my chemist forgot to bring some home

I didn't realise just how easy it is to mash in with a 1V 'Full Volume' system, tip the grain in and stir job done . . . but then at 4.8L/Kg mash ratio that is a loose mash.

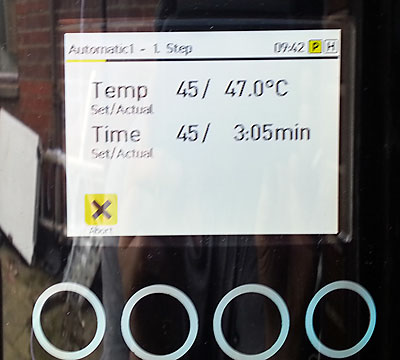

Well the mash is under way, remember that this is a modified Hochkurz mash and this 45C initial step is to help produce the precursors of 4 Vinyl Guaiacol responsible for the spicy clove notes of good wheat beeers

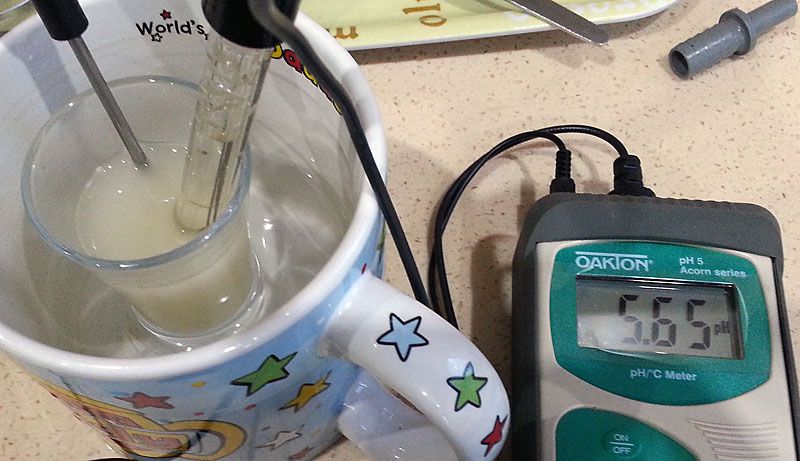

A sample drawn at 10 minutes shows that the pH is within the acceptable range of 5.2 to 5.7, but it is a touch high for a pale beer where I would prefer it to be 5.4. I added 4.5g of calcium chloride to the mash to adjust this, as the higher mash pH is probably due to an insufficient calcium level. This will boost the calcium to 75, and chloride to around 100 mg/L, giving me a balanced 1:1 sulphate : chloride ratio.

So we are at the next mash step, Braumeisters hit about a 1C per minute temperature change (Outside with no jacket and a wind blowing) This will favour beta amylase.

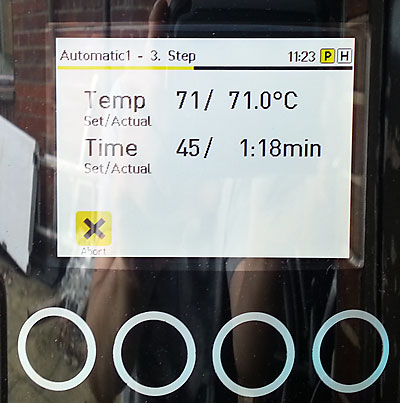

The third step at 71C favours alpha amylase, and should help mop up any unconverted starch that has been left lying around.

At this stage the wort has cleared really well, I was concerned as it was very milky previously

Purely for curiosity, I took a gravity reading as well, 10.5 Brix is about 1.042 so getting close to where I want to be already.

4 minutes to the end of the mash

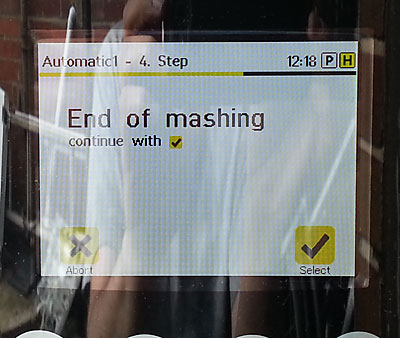

At the end of the mash, this was the clarity of the wort. It doesn't have to be this bright, and indeed a bright wort is no idication that you will have a bright beer. It looks good though

It's an interesting exercise lifting the malt tube, not particularly difficult or heavy, but interesting. I sparged with 5 Litres of 72C water. No shot but preboil gravity reading was 1.049 at 24 Litres

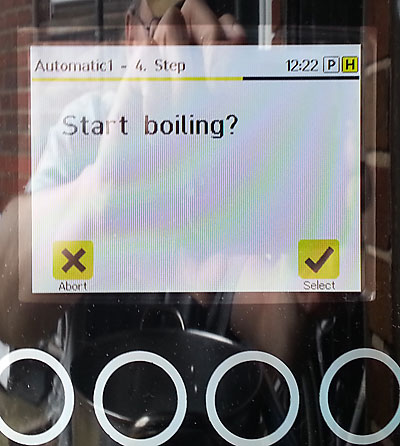

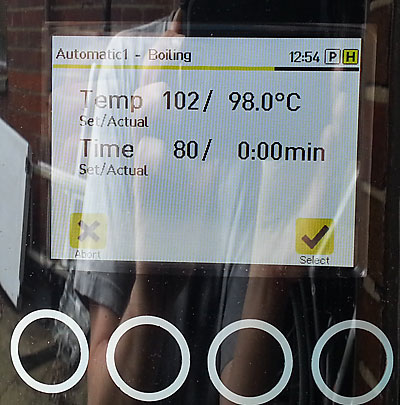

The Braumeister does lead you through the process pretty well

Almost ready to start boiling

Just coming up to the boil now

50g Of Hallertau Mittelfruh hops weighed out and ready to go

All tucked up in it's bodged jacket to boil for 80 minutes

And a good rolling boil with the hops in - 60 minutes left