Brewed (roughly) the same SNPA clone(ish) that I often brew, but this time with WLP002 instead of US05 to try and get a bit more interest going flavourwise. First time with WLP002, and only second time with any liquid yeast. Mashed a bit lower at 65C (usually 67) to try and get a similar FG as I do with the US05.

Built a cheap stir plate in the usual way - this was my first starter on it, 1.2L with a sachet of WLP002. It vortexes well and the stirplate lasted the full 24 hours no problems.. serious clumps of yeast by the end, but this pic is from the beginning:Recipe Specifications

--------------------------

Boil Size: 29.00 l

Post Boil Volume: 26.00 l

Batch Size (fermenter): 22.00 l

Bottling Volume: 19.00 l

Estimated OG: 1.053 SG

Estimated Color: 11.0 EBC

Estimated IBU: 35.7 IBUs

Brewhouse Efficiency: 70.00 %

Est Mash Efficiency: 79.5 %

Boil Time: 60 Minutes

Ingredients:

------------

Amt Name Type # %/IBU

5.00 kg Pale Malt, Maris Otter (5.9 EBC) Grain 1 94.3 %

0.25 kg Caramel Malt - 10L (Briess) (19.7 EBC) Grain 2 4.7 %

0.05 kg Caramel/Crystal Malt - 60L (118.2 EBC) Grain 3 0.9 %

10.00 g Magnum [14.00 %] - First Wort 60.0 min Hop 4 16.2 IBUs

15.60 g Perle [8.00 %] - Boil 30.0 min Hop 5 10.1 IBUs

0.91 Items Whirlfloc Tablet (Boil 15.0 mins) Fining 6 -

36.40 g Cascade [6.80 %] - Boil 10.0 min Hop 7 9.4 IBUs

52.22 g Cascade [6.80 %] - Boil 0.0 min Hop 8 0.0 IBUs

1.0 pkg English Ale (White Labs #WLP002) [35.49 Yeast 9 -

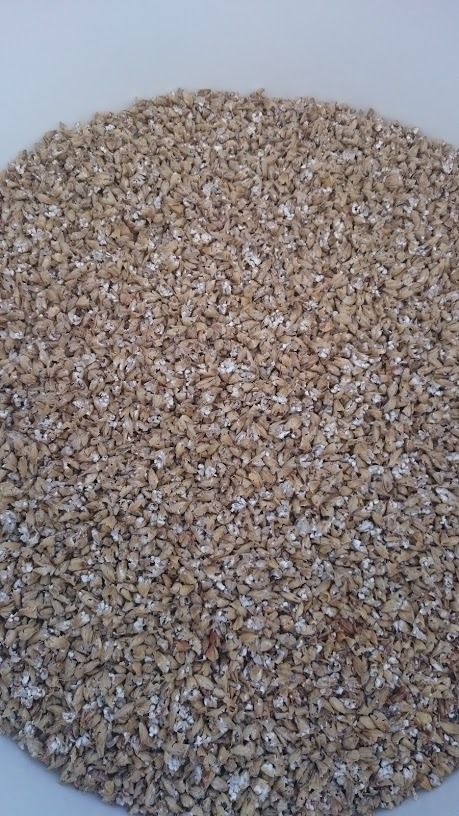

Bought myself a Brewferm malt mill as an early Christmas present. First time milling malt at home, one of the reasons being that I wanted to try conditioning the malt. Conditioned the 5kg of grain with 100ml sprayed water and milled at 0.7mm. The crush was amazing - almost all hulls intact, and very fluffy - you could stuff a pillow with it!

Mashing in, I got a very gelatinous mash straight away - wallpaper paste almost - and quite a few dough-balls. I was slightly panicked. I stirred for a good few minutes then let it sit for another few minutes before turning on the re-circ pump. Stuttered a bit at first (only a 12V solar), and I had to back it up once (blow through the other end), but it hit it's stride after that as the mash thinned.

Also had to replace the PID in my getto HERMS rig - glad to say the new one worked without issues. Here it is ramping up to mash-out at 75C:

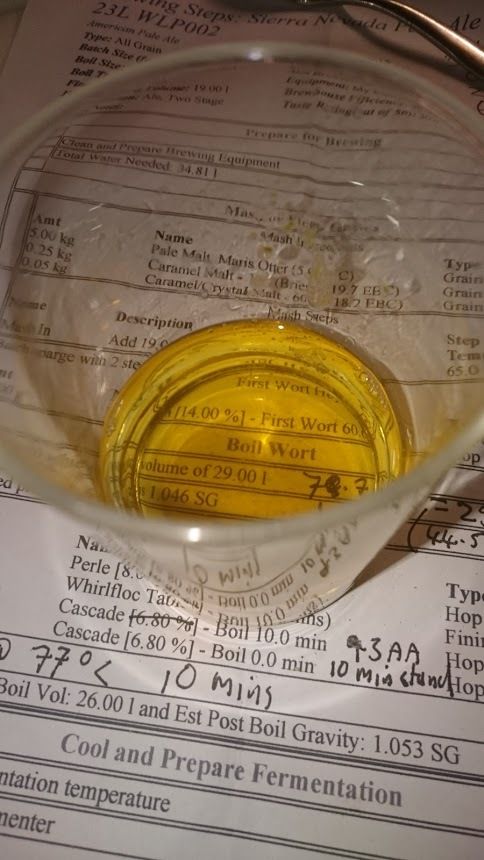

First runnings hitting 10g of Magnum first wort hops:

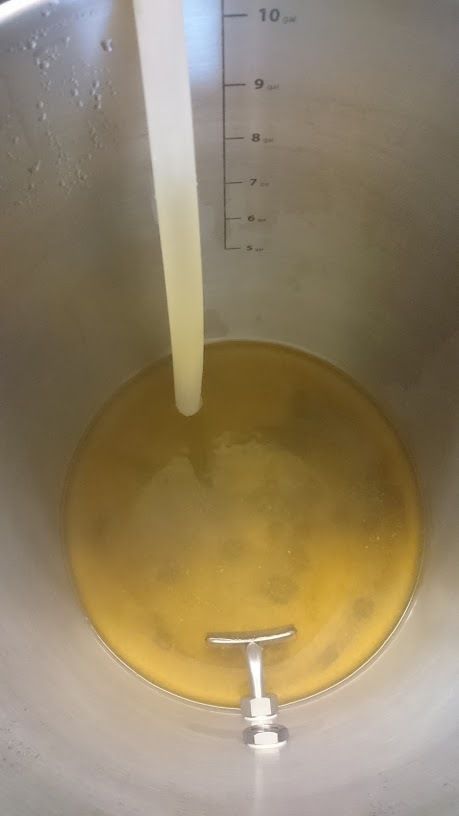

The end of the last runnings, burner on - almost at the boil by the time the mash tun is empty:

The boil - I've mentioned it a few times, but I am really loving this induction hob. This is 29L on the boil at a 5C ambient temp. Doubt I'll be brewing much colder than this:

Cold break: