Happy to announce after 2 weeks from SmartPID launching that the second application on top of the SmartPID platform is nearly ready and is completely dedicated to home brewing process automation

What is new and different compared to the standard basic application (smart thermostat)?

Substantially Smart Home Brewing App adds to a standard temperature control features all the process automation and workflow to manage all typical steps for beer making. We have customized vertically the SW for the specific application leveraging all the basic features available on the platform

Each vertical application has off course it’s own set of data, process parameter and configuration and so is the smart home brewing app that execute all process steps according to in memory “recipe”and controls HW resources (heating elements, pump/stirrer, buzzer ) in automatic way

These are main characteristic of the smart HB application

- -Single vessel (BIAB/RIMS) or two vessel (MASH + HLT) process management

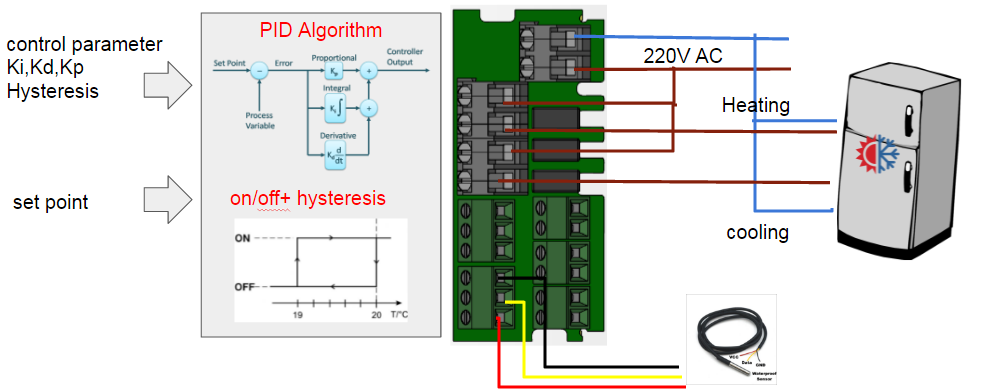

-Electric heating (PID/PWM) or Gas Fired heating (ON/OFF)

-Recirculating pump or motorized mixer management

-NTC/DSB18B20 temperature probe

-Internal or external (in recirculating circuit) temp probe position

-Step Mash management (mash in/out and 6 step mash)

-Boil management with overboil and power control (electric only)

-Hop addition alarms

-Whirlpool management (hot or cold)

-Cooling management

-Full recipe management (new / edit /clone /delete)

-Mash profile

-Boil duration and hop addition time

-10 possible recipe in memory

-Delay start for brew day programming

- -Log of all process data locally in the EEPROM

-Push of process data via wifi to thingspeak server

-Download of process data via USB (CSV format)

-Web visualization of process data

-SamrtPID dedicated smartphone app for data visualization (android only)

Even if it’s very easy to configure smartPID via local menu the possibility to have a web user area with all parameters and recipe as well all the log data of previous brew day we believe is a real plus. In order to simplify the recipe process from definition to run mode also import of mash and boil profile from major SW like Beersmith is in feasibility stage

In next posts we try to show a real case of set up and cabling for BIAB equipments and a video with complete overview of the functions trough the EMULATOR

arzaman

http://smartpid.com

https://www.facebook.com/smartPID