Stainless Hot Water Cylinder conversion - ideas

Re: Stainless Hot Water Cylinder conversion - ideas

at the moment, I put my plastic fermenters in a larder fridge, and use a tubular heater and the fridge to adjust the temp.

this new 100L fermenter won't fit into the larder fridge, so will have to find a new way of heating and crash chilling... any suggestions?

my current plan is to turn my larder fridge into a kegerator and maybe use my small chest freezer as a possible glycol recirc setup. i'm most concerned with the ability to crash chill. alternatively i could use the chest freezer and build an extension enclosure above it and use the freezer to crash chill

this new 100L fermenter won't fit into the larder fridge, so will have to find a new way of heating and crash chilling... any suggestions?

my current plan is to turn my larder fridge into a kegerator and maybe use my small chest freezer as a possible glycol recirc setup. i'm most concerned with the ability to crash chill. alternatively i could use the chest freezer and build an extension enclosure above it and use the freezer to crash chill

Planning: BrewEasy system build; possibly a Wychwood Hobgoblin Gold clone

Fermenting: Simcoe SMASH

Drinking: Cascade Centennial Pale

Fermenting: Simcoe SMASH

Drinking: Cascade Centennial Pale

-

Fil

- Telling imaginary friend stories

- Posts: 5229

- Joined: Sun Oct 16, 2011 1:49 pm

- Location: Cowley, Oxford

Re: Stainless Hot Water Cylinder conversion - ideas

A pretty common solution is a shelf chiller with a recirc/python pump and a Stainless Immersion coil.

ebay should provide a reasonably priced chiller in your area unless extremely remote sooner or later, and also supply a square product coil from a larger chest chiller for a budget thin walled IC option.

ebay should provide a reasonably priced chiller in your area unless extremely remote sooner or later, and also supply a square product coil from a larger chest chiller for a budget thin walled IC option.

ist update for months n months..

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

Re: Stainless Hot Water Cylinder conversion - ideas

Cheers Fil, I see the logic but I'd rather not have anything in the fermenting wort, I'd prefer to have something round the outside of the pot, like this viewtopic.php?f=6&t=48812Fil wrote:A pretty common solution is a shelf chiller with a recirc/python pump and a Stainless Immersion coil.

Seems to suggest that the coils could even be plastic beer line...

Planning: BrewEasy system build; possibly a Wychwood Hobgoblin Gold clone

Fermenting: Simcoe SMASH

Drinking: Cascade Centennial Pale

Fermenting: Simcoe SMASH

Drinking: Cascade Centennial Pale

-

Fil

- Telling imaginary friend stories

- Posts: 5229

- Joined: Sun Oct 16, 2011 1:49 pm

- Location: Cowley, Oxford

Re: Stainless Hot Water Cylinder conversion - ideas

enclosed behind effective insulation an external chiller coil will cool eventually, but forming copper to make a good positive contact, which is absolutely necessary for any form of efficient transfer, all the way round and keeping it from springing off is a challenge  get a couple of extra rolls of gaffer tape, plastic tube will also work eventually but again wont be efficient..

get a couple of extra rolls of gaffer tape, plastic tube will also work eventually but again wont be efficient..

lid entry SS coils and thermowells can be flame sanitised if concerned.. But I am biased have gone that way myself..

If determined then insulation will be key just dont expect external limited contact coils to be very efficient but if you pump enough cold in it will penetrate eventually.. check out thick armoflex insulation sleeves for the transfer pipes, its worth the lil extra for the flexibility and higher insulation values

then insulation will be key just dont expect external limited contact coils to be very efficient but if you pump enough cold in it will penetrate eventually.. check out thick armoflex insulation sleeves for the transfer pipes, its worth the lil extra for the flexibility and higher insulation values

lid entry SS coils and thermowells can be flame sanitised if concerned.. But I am biased have gone that way myself..

If determined

ist update for months n months..

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

Fermnting: not a lot..

Conditioning: nowt

Maturing: Challenger smash, and a kit lager

Drinking: dry one minikeg left in the store

Coming Soon Lots planned for the near future nowt for the immediate

Re: Stainless Hot Water Cylinder conversion - ideas

This looks great!

The big opening on the lid of your boiler looks like a 2.25" bsp immersion socket. I use a 2" opening on the lid of a 100L boiler, and it's a good enough size to vent the steam from that size of boil. I use it with 2" tube going to a condenser from a commercial steam oven. Very hard to get adaptors for 2-1/4" BSP though, to get to a hosetail etc. (unless you don't mind using brass). It would be easy enough to slide some tubing (like wire reinforced PVC, maybe 2.5" diameter) right over the fitting and bring that to a vent or fan. I have a 2.25" socket and some 2" tubing - I could try it for size and let you know if it fits.

If you're using a glycol chiller with a coil that goes into the beer - I remember a chiller sales man warning me once about how toxic glycol is, and only to use it in cooling systems external to tanks in case of leaks. Maybe you would be fine, but water is obviously the safe option.

The big opening on the lid of your boiler looks like a 2.25" bsp immersion socket. I use a 2" opening on the lid of a 100L boiler, and it's a good enough size to vent the steam from that size of boil. I use it with 2" tube going to a condenser from a commercial steam oven. Very hard to get adaptors for 2-1/4" BSP though, to get to a hosetail etc. (unless you don't mind using brass). It would be easy enough to slide some tubing (like wire reinforced PVC, maybe 2.5" diameter) right over the fitting and bring that to a vent or fan. I have a 2.25" socket and some 2" tubing - I could try it for size and let you know if it fits.

If you're using a glycol chiller with a coil that goes into the beer - I remember a chiller sales man warning me once about how toxic glycol is, and only to use it in cooling systems external to tanks in case of leaks. Maybe you would be fine, but water is obviously the safe option.

Re: Stainless Hot Water Cylinder conversion - ideas

Absolutely, I will only use antifreeze/glycol in a cooling coil externally wrapped around the tankNunez100 wrote:If you're using a glycol chiller with a coil that goes into the beer - I remember a chiller sales man warning me once about how toxic glycol is, and only to use it in cooling systems external to tanks in case of leaks. Maybe you would be fine, but water is obviously the safe option.

Planning: BrewEasy system build; possibly a Wychwood Hobgoblin Gold clone

Fermenting: Simcoe SMASH

Drinking: Cascade Centennial Pale

Fermenting: Simcoe SMASH

Drinking: Cascade Centennial Pale

Re: Stainless Hot Water Cylinder conversion - ideas

Ah, okay, I read that wrong then.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Re: Stainless Hot Water Cylinder conversion - ideas

Not that it'll matter here, but I think there's two main types of glycol, ethylene and propylene glycol. One of which is a lot less toxic than the other.

Re: Stainless Hot Water Cylinder conversion - ideas

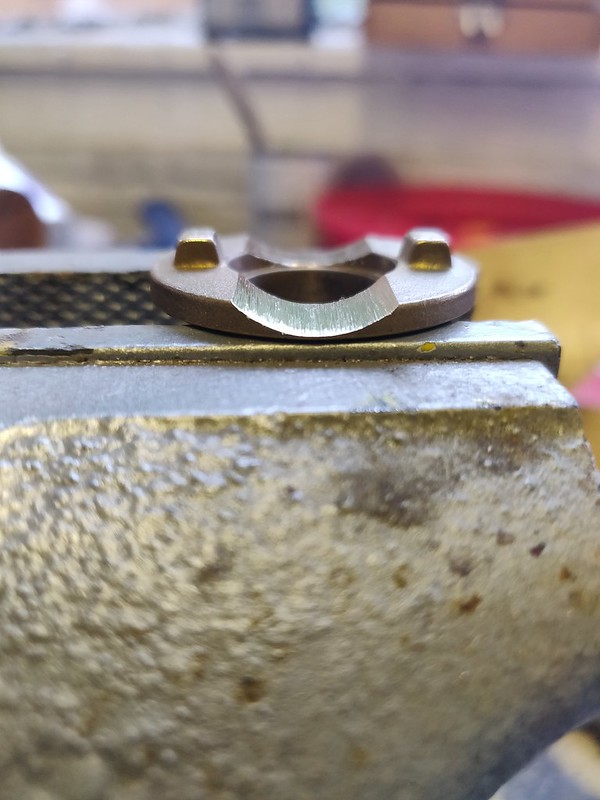

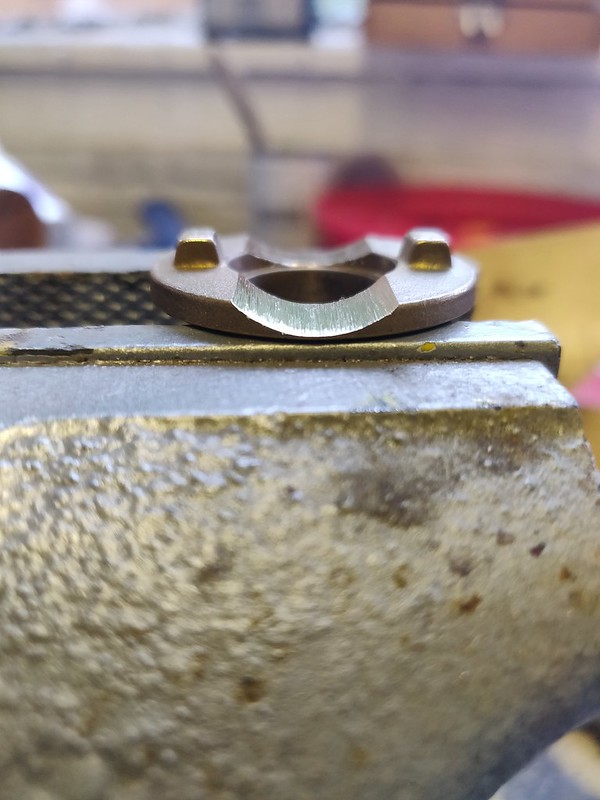

slow progress on this build due to several ongoing family health problems, which are taking their toll. I'm trying to gather some parts in the background - has anyone got a link to a stainless 1" BSP flanged nut?

like https://www.bes.co.uk/1in-flanged-hexag ... oCK7_w_wcB but stainless ?

like https://www.bes.co.uk/1in-flanged-hexag ... oCK7_w_wcB but stainless ?

Planning: BrewEasy system build; possibly a Wychwood Hobgoblin Gold clone

Fermenting: Simcoe SMASH

Drinking: Cascade Centennial Pale

Fermenting: Simcoe SMASH

Drinking: Cascade Centennial Pale

Re: Stainless Hot Water Cylinder conversion - ideas

Hi guys,

I've had a bit of interest in this project, so I thought I'd reply to the original post. EportJake (hi Jake) sent the below:

Hi there. I've been trawling the net re SS hot water cylinder conversions, and one of your posts came up from many moons back. I'm considering doing this kind of thing myself, so I was after some advice seeing as you have some experience in this sort of thing. How did your conversion go? Are you still using it? Any issues? Thanks, Jake.

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr

At the moment, I'm working on a single vessel brewery project, so this stainless cylinder conversion has taken a back seat. The conversion was fairly straightforward - you'll need an angle grinder though for the lid. I have q-maxed out two Peco element holes, and three other 34mm/1.25" holes. I could have just used the original 22mm fittings, but I didnt want the fittings to protrude that much externally. The vessel itself seems sturdy and I would recommend this type of vessel for a boiler/HLT project.

I am working on producing a Braumeister-esq copy at the moment, for a 23L brew length, using 50L and a 21L Bergland pots. If successful, I'm planning on making a further Braumeister-esq copy, aimed at producing 50/60L, using this stainless cylinder as the main vessel with possibly a 50L malt pipe inside. I may mount the whole thing in my portable stainless catering table (kind of like https://aussiehomebrewer.com/threads/hu ... ery.87002/ , but WAY less professional!!!!)

I've had a bit of interest in this project, so I thought I'd reply to the original post. EportJake (hi Jake) sent the below:

Hi there. I've been trawling the net re SS hot water cylinder conversions, and one of your posts came up from many moons back. I'm considering doing this kind of thing myself, so I was after some advice seeing as you have some experience in this sort of thing. How did your conversion go? Are you still using it? Any issues? Thanks, Jake.

Untitled by Ben, on Flickr

Untitled by Ben, on Flickr Untitled by Ben, on Flickr

Untitled by Ben, on Flickr Untitled by Ben, on Flickr

Untitled by Ben, on FlickrAt the moment, I'm working on a single vessel brewery project, so this stainless cylinder conversion has taken a back seat. The conversion was fairly straightforward - you'll need an angle grinder though for the lid. I have q-maxed out two Peco element holes, and three other 34mm/1.25" holes. I could have just used the original 22mm fittings, but I didnt want the fittings to protrude that much externally. The vessel itself seems sturdy and I would recommend this type of vessel for a boiler/HLT project.

I am working on producing a Braumeister-esq copy at the moment, for a 23L brew length, using 50L and a 21L Bergland pots. If successful, I'm planning on making a further Braumeister-esq copy, aimed at producing 50/60L, using this stainless cylinder as the main vessel with possibly a 50L malt pipe inside. I may mount the whole thing in my portable stainless catering table (kind of like https://aussiehomebrewer.com/threads/hu ... ery.87002/ , but WAY less professional!!!!)

Planning: BrewEasy system build; possibly a Wychwood Hobgoblin Gold clone

Fermenting: Simcoe SMASH

Drinking: Cascade Centennial Pale

Fermenting: Simcoe SMASH

Drinking: Cascade Centennial Pale

Re: Stainless Hot Water Cylinder conversion - ideas

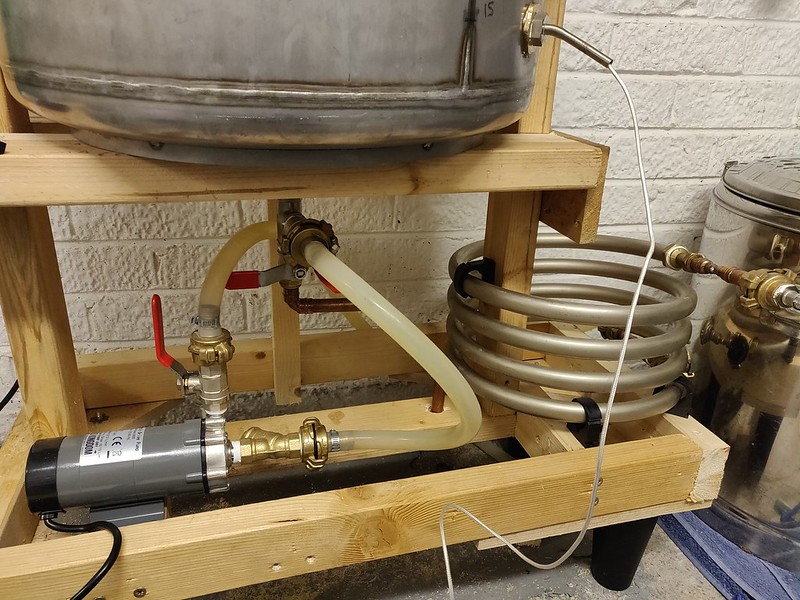

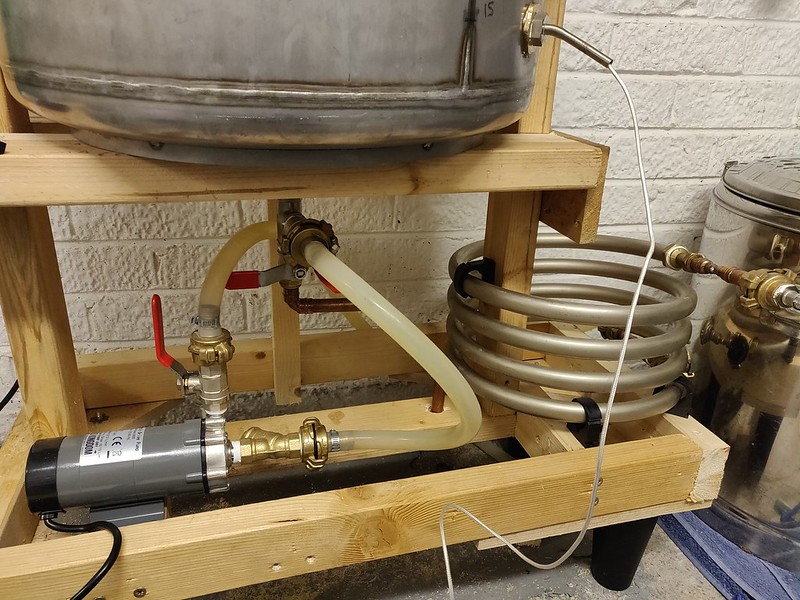

A little thread update

Its been a while, but I've been tinkering with this project again and have used the cylinder for a K-RIMS project (kettle rims, apparently!). Its a two vessel setup. I have made a timber frame, to which I intend to add castors. I have made the hot water cylinder bottom draining, and have added a hard plumbed "dump hole", for want of a better term, to make cleaning easier. I brewed 50 litres of Nelson Sauvin SMASH last week on the system. A few creases to be ironed out, but all in all a good start. I need to finalise my recirc plans with the mash tun thermopot. It was great to be able to open the cleaning valve, use a garden sprayer and dump all the hop debris etc into the drain in my garage. Easiest brewday cleanup so far.

IMG_20180823_220021 by Ben, on Flickr

IMG_20180823_220021 by Ben, on Flickr

IMG_20180823_220015 by Ben, on Flickr

IMG_20180823_220015 by Ben, on Flickr

IMG_20180823_220010 by Ben, on Flickr

IMG_20180823_220010 by Ben, on Flickr

IMG_20180819_154541 by Ben, on Flickr

IMG_20180819_154541 by Ben, on Flickr

IMG_20180826_163307 by Ben, on Flickr

IMG_20180826_163307 by Ben, on Flickr

IMG_20180826_121507 by Ben, on Flickr

IMG_20180826_121507 by Ben, on Flickr

IMG_20180826_191238 by Ben, on Flickr

IMG_20180826_191238 by Ben, on Flickr

IMG_20180704_203111 by Ben, on Flickr

IMG_20180704_203111 by Ben, on Flickr

Its been a while, but I've been tinkering with this project again and have used the cylinder for a K-RIMS project (kettle rims, apparently!). Its a two vessel setup. I have made a timber frame, to which I intend to add castors. I have made the hot water cylinder bottom draining, and have added a hard plumbed "dump hole", for want of a better term, to make cleaning easier. I brewed 50 litres of Nelson Sauvin SMASH last week on the system. A few creases to be ironed out, but all in all a good start. I need to finalise my recirc plans with the mash tun thermopot. It was great to be able to open the cleaning valve, use a garden sprayer and dump all the hop debris etc into the drain in my garage. Easiest brewday cleanup so far.

IMG_20180823_220021 by Ben, on Flickr

IMG_20180823_220021 by Ben, on Flickr IMG_20180823_220015 by Ben, on Flickr

IMG_20180823_220015 by Ben, on Flickr IMG_20180823_220010 by Ben, on Flickr

IMG_20180823_220010 by Ben, on Flickr IMG_20180819_154541 by Ben, on Flickr

IMG_20180819_154541 by Ben, on Flickr IMG_20180826_163307 by Ben, on Flickr

IMG_20180826_163307 by Ben, on Flickr IMG_20180826_121507 by Ben, on Flickr

IMG_20180826_121507 by Ben, on Flickr IMG_20180826_191238 by Ben, on Flickr

IMG_20180826_191238 by Ben, on Flickr IMG_20180704_203111 by Ben, on Flickr

IMG_20180704_203111 by Ben, on FlickrPlanning: BrewEasy system build; possibly a Wychwood Hobgoblin Gold clone

Fermenting: Simcoe SMASH

Drinking: Cascade Centennial Pale

Fermenting: Simcoe SMASH

Drinking: Cascade Centennial Pale

Re: Stainless Hot Water Cylinder conversion - ideas

Is the full 50l batch for yourself or do you distribute to friends etc?

Sent from my iPhone using Tapatalk Pro

Sent from my iPhone using Tapatalk Pro

Sabro Single Hop NEIPA 25/02/20 CLICK ME to monitor progress with Brewfather & iSpindel

Re: Stainless Hot Water Cylinder conversion - ideas

This batch is mostly for me, as I've run out of beer. Planning 25 litres in a King keg and the rest in bottles. I'm planning to use this build for larger batches really, although 15 litres covers the elements so at least I've got the option of smaller amounts. I tend to use my other build, the MaltMother, for small batches as its a 4 hour brew day with that. My next use of the K-RIMS build will be for a 75 litre batch of Christmas stout, which will be shared out. I'll split that batch into 3 x 25 litre batches and do one coffee, one bourbon and vanilla, and the third one is yet to be decided.

Planning: BrewEasy system build; possibly a Wychwood Hobgoblin Gold clone

Fermenting: Simcoe SMASH

Drinking: Cascade Centennial Pale

Fermenting: Simcoe SMASH

Drinking: Cascade Centennial Pale

Re: Stainless Hot Water Cylinder conversion - ideas

How easy is that bad boy to clean and how do you do it?

Re: Stainless Hot Water Cylinder conversion - ideas

It's pretty simple - it's bottom draining with a curve to the base, so most of the liquid drains out bar about 100ml, which I use paper towels to soak up. I heat up the water to 60ish degrees and mix in oxiclean. Then recirculate this through the pump, the counter flow chiller and back into the pot. I've got a 15mm copper pipe assembly after the ball valve to the pump inlet to drain out through, so I just position that over my drain and spray cold water in from the top of the cylinder. I hate cleaning so I tried to make it as easy as possible!

Planning: BrewEasy system build; possibly a Wychwood Hobgoblin Gold clone

Fermenting: Simcoe SMASH

Drinking: Cascade Centennial Pale

Fermenting: Simcoe SMASH

Drinking: Cascade Centennial Pale