Okay, what follows is probably a bit convoluted and it's spread over a few days - not everything went according to plan. But, it's a fairly accurate account of my first ever all grain brew.

THURSDAY:

After I'd finished faffing around making a new hop stopper and hoping to brew on Saturday, I boiled up some DME to make a 1.5 litre yeast starter.

Boiling extract

When cool, I pitched a bottle of WPL002 and stuck it in my fermenting cupboard.

Yeast starter

For my first AG, I didn't want to get too bogged down with water treatment, so I followed the advice on 'simple water treatment' from Graham's BYOBRA book.

SATURDAY

On Saturday morning I found that the boiler had leaked overnight. I'd lost about a litre of treated liquor

Bugger!

I emptied the boiler into a couple of fermenting bins and took the boiler apart. It seemed to be leaking from between the boiler wall and bottom, so I got onto JBK to ask questions about food grade silicone sealant, hoping I could salvage both the boiler and the brewday...

On closer inspection, I found the leak path was actually around the element.

Leak path

One edge of the element has always looked a bit dented. I took the element out and carefully flattened the edge, then reseated it on the rubber gasket.

I filled it up to check whether it was watertight, but by this time most of the morning had gone & brewday was effectively over, so SWMBO took me to do some 'research' at the local.

Research

Purity Pure Ubu for me and Harviestoun Schiehallion for SWMBO.

SUNDAY

Satisfied with the fixed boiler, I refilled it with the treated liquor and set the thermostat for 80C.

Start again!

As a side note: I've marked out my plastic spoon with notches to measure the amount of liquid in the boiler - something I should've done for my first (extract) brew. Boiling the water during treatment on Friday meant that I could measure how much I lost to evaporation - I reckon on around 2 litres per 30 minutes when on a rolling boil!

While the boiler was heating up to strike temperature, I weighed out the grain.

Grain shot!

I boiled a kettle and poured it into the mashtun to preheat it.

Preheating mashtun

Then, the boiler conked out!

This time it lost all power... I checked the fuse in the plug (fine,) I checked the socket by plugging something else into it (fine,) I changed the fuse on the boiler anyway... Nothing. Totally dead.

So, once again, I drained the liquor into fermenting bins and took the boiler apart

This time, the internal fuse had popped. There was a slightly loose spade terminal attached to the the element that looked like it could've been arcing - I fixed that, put it back together and tested it.

Back in business!

Boiler filled again, liquor bought up to strike temperature, mashtun preheated... With the liquor at 80C, I started to fill the mashtun. But, the liquor temperature in the mashtun measured just 72C

I waited for the liquor temp to drop to 74C and added the grain!

SWMBO got in on the act too - with some shameless advertising for her beer blog.

My glamorous assistant

Doughing in

She'll probably blog about it - about how she did all the hard work...

I also took a little juice out of the tun to test the pH. By my reckoning it was 5.4, but to be honest I think the pH papers I bought off Ebay leave a bit to be desired...

Anyway, we left the mash (covered with a quilt, just in case of heat loss from the lid) for 90 minutes and I weighed out the hops.

Hops

At the end of 90 minutes, the mash temp was bang on 66C. Well chuffed with the coolbox!

I topped up the mashtun with the required amount of (hotter) liquor - according to the Batch Sparge and Boil Volume Calculator, stirred it up and started to run off the first batch.

First runnings of first batch

Pretty cloudy at this stage, so I recirculated the first few litres back into the mashtun.

Running off

I managed to get just under 13 litres on the first batch. I was aiming for 14 litres, 'cos that's what the calculator told me

On the second batch, once again I collected 13 litres - so 26 litres of wort went into the boiler instead of the calculated 28

26 litres of wort in the boiler

Now, realising that I'd lose around 2 litres per half hour, I decided to reduce the boil time to 60 minutes rather than 90. This way I thought I'd have a chance of keeping enough wort for the 19 litre brewlength. Also, I read that a lot of JBK members tend to only boil for an hour (or did I dream that..?)

Once the wort was in the boiler, I had to take a break to sell my old car. Does life always get in the way of a brew..?

One hour later and readies in my pocket... (well, SWMBO's handbag actually...) It was back to brewday!

Anyway, here's the rolling boil...

Rolling boil

I weighed the late hops and readied a protofloc tab...

Late hops and 'floc

...chucked them in at 60mins (boiling for another 10 minutes) with the immersion chiller to sterilise it...

Chiller in

...and turned the boiler off at 1 hour 10 minutes, turned the chiller water on & had a cup of tea

Cooling

At the end of crash cooling, I had 21 litres left in the boiler... pretty much what I expected with the evaporation rate of my boiler...

I poured most of the wort off the yeast cake, leaving around 500ml to swirl around...

Reduced starter

...and started the run off into the fermenting bin.

The gravity (with the wort at 25C) read 1051. Not too far off the 1054 I was aiming for.

Gravity reading

Running off into fermenting bin

I took a sample later on during the run off - looking good!

Nice and clear!

After some vigorous aerating, I pitched the yeast...

Pitching yeast

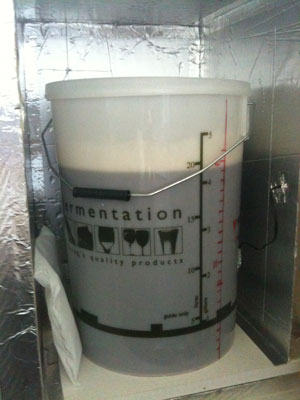

...and put it away in the fermenting cupboard.

Tucked away in fermenting cupboard

Today, it looks happy enough

Monday morning

Despite the boiler woes and the stop-start nature of the brewday(s) I really enjoyed it. Looking forward to tasting the result

I made beer and I feel like a GOD!

Cheers!

FB.