The stairs upto the hopper on the second level.

This is the hopper where the crushed grain is fed into the mash tun.

The mash tun, the pipe above is an archimedes screw feeding the malt from the hopper into the mash tun, Ian is spreading the malt around with a shovel to get an even bed.

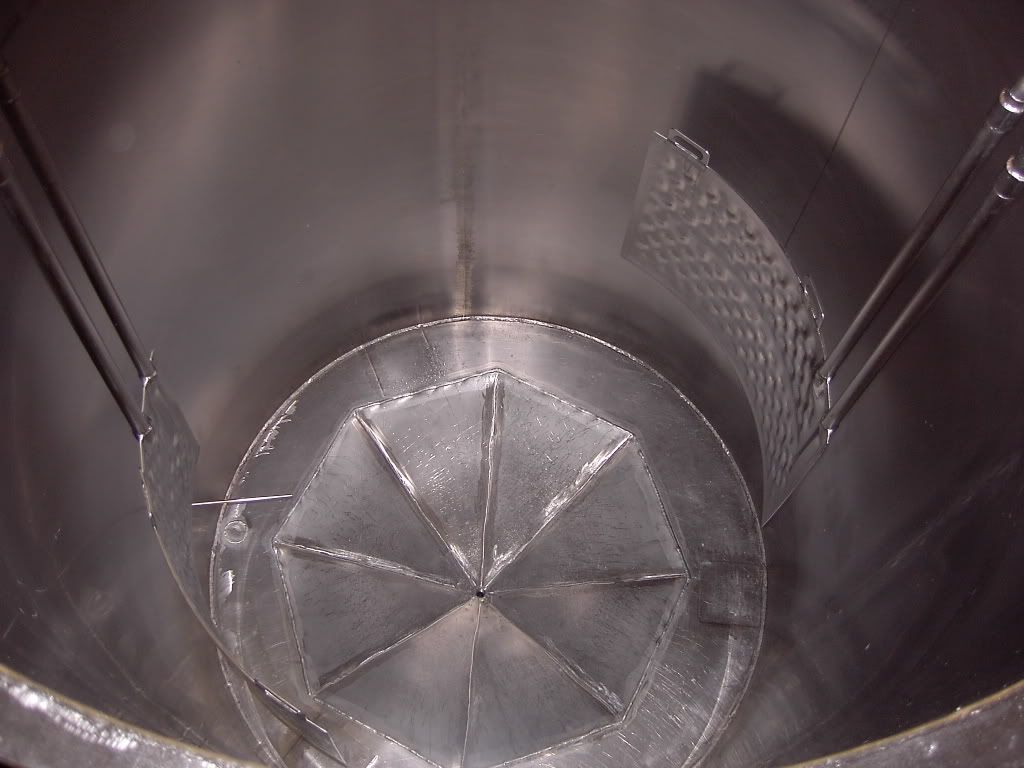

Inside of the Boiler

The HLT

Sparge arm inside the Mash tun doing it's thang.

Boiler filling up.

Underback and Plate chiller.

Hops being added.

This shot is of the compacted spent grain ready for removal into sacks.

This is where the stuff ends up, conical fermenter with plate chillers at the side and temp. probe sticking out on the left.

PH check.

Acid washing of yeast before it's put into the fresh wort

Start of a previous batch, early stage of fermentation.

A more vigorous fermentation at its later stage.

Storage area, there are two rows of these containers, kept under pressure before -

- being moved to keg, these are a mixture of plastic and metal.

This area is where the kegs are washed.

They used to bottle using this method, which many of us are familiar with!

Now the stuff is moved to containers much like this one before being transported for bottling (this one contains caustic soda mind)

I managed to get a box of nice beers and a better understanding of how a larger brewery operates, they currently brew four days a week and further info can be found here -

http://www.purplemoose.co.uk/

If you have a mooch around in the news archives you can see how this was all put together and get a better picture of how big the place is.

A big thanks to Lawrence and all his team.

Cheers.