chiller - what do I do now?

chiller - what do I do now?

My ex-eBay Maxi 110 seems to work, and chills, which is great.

Now if I want to chill my fermenter, I think I need a cooling spear, and a couple of lengths of hose, and I can recirculate the cold water round the python loop.

However I think I need a controller - ATC800 or TC-10, but I can't remember whether this should switch the water pump or the refrigeration compressor. My instinct is to run the water pump all the time, so the tank doesn't bung up with ice, and use the controller to switch the compressor on and off.

Does this sound right please?

All suggestions gratefully received...

Now if I want to chill my fermenter, I think I need a cooling spear, and a couple of lengths of hose, and I can recirculate the cold water round the python loop.

However I think I need a controller - ATC800 or TC-10, but I can't remember whether this should switch the water pump or the refrigeration compressor. My instinct is to run the water pump all the time, so the tank doesn't bung up with ice, and use the controller to switch the compressor on and off.

Does this sound right please?

All suggestions gratefully received...

Re: chiller - what do I do now?

I have a maxi 110 and ATC800 controlling my FV, however, mine covers cooling and heating and my choice is to run the pump and compressor/heating as one. The FV is an 80L thermobox with a 6 metre, 10mm od attemperating coil fitted from the bottom.

Mine is wired such that the pump and compressor come on together for cooling and the pump and heating element come on together for heating. So unless it is calling for heating or cooling then nothing is running. I wont go into the wiring because you know more about that than I do but it utilises two 10A double pole relays, and one of these heater (though not necerssarily from this place) fitted in the pump circuit.

Mine is wired such that the pump and compressor come on together for cooling and the pump and heating element come on together for heating. So unless it is calling for heating or cooling then nothing is running. I wont go into the wiring because you know more about that than I do but it utilises two 10A double pole relays, and one of these heater (though not necerssarily from this place) fitted in the pump circuit.

Re: chiller - what do I do now?

Thanks guys.

I have several old heating belts so I'll probably try one of those to start with.

Chris - didn't Vossy post about things freezing-up with the pump going on and off?

The plug-in power meter says the fan and the pump only eat 23 watts, but obviously it would be less lecky if I didn't run them all the time.

I have several old heating belts so I'll probably try one of those to start with.

Chris - didn't Vossy post about things freezing-up with the pump going on and off?

The plug-in power meter says the fan and the pump only eat 23 watts, but obviously it would be less lecky if I didn't run them all the time.

Re: chiller - what do I do now?

Most useful - thanks Chris!

I've ordered a Fortex TC-10 (only £2.99 for P&P!) and I need a box for it, hoses, cooling spear...

I was wondering about a small-diameter coiled IC which could pass through the neck of a Young's budget fermenter - would be more difficult to sanitise than a straight stick though.

I've ordered a Fortex TC-10 (only £2.99 for P&P!) and I need a box for it, hoses, cooling spear...

I was wondering about a small-diameter coiled IC which could pass through the neck of a Young's budget fermenter - would be more difficult to sanitise than a straight stick though.

Re: chiller - what do I do now?

TC-10 in box, new front and back panels bodged onto old Lacie drive shell:

and plugged-in:

I should have done something about the colour temperature of the pictures

The sensor is a neg-coefficient thermistor, which I've made to plug-in using a 4-pin XLR plug and socket - 4-pin because 3-pin must be audio, while the only other thing I have with 4-pin in the house is the 12V feed to my ancient Arriflex, and that is wired with different pins.

The socket isn't in the ideal place - I should have had it on the far side of the fuse-holders from the TC-10 - but I forgot to make room for a hole, took the box indoors to check, and found another socket on the table. Ah. Rude Word...

and plugged-in:

I should have done something about the colour temperature of the pictures

The sensor is a neg-coefficient thermistor, which I've made to plug-in using a 4-pin XLR plug and socket - 4-pin because 3-pin must be audio, while the only other thing I have with 4-pin in the house is the 12V feed to my ancient Arriflex, and that is wired with different pins.

The socket isn't in the ideal place - I should have had it on the far side of the fuse-holders from the TC-10 - but I forgot to make room for a hole, took the box indoors to check, and found another socket on the table. Ah. Rude Word...

-

Scooby

Re: chiller - what do I do now?

Very elegant edit1now  The work you post on here is always very neat and precise.

The work you post on here is always very neat and precise.

I have most of the parts to do a similar job, chiller, TC-10 etc and the bits required to make a lid for the FV. You mentioned polypropylene and chopping boards iirc, I actually got a 250mm x 250mm x 5mm sheet of Acetal from these people good prices I think.

BTW do you know where can I get small cable glands (3mm) for the probe entry into the FV? I'm using a ATC-800 probe that is round as opposed to twin wire for more effective sealing, apparently it reads 1c less but as the TC-10 can be calibrated isn't a problem.

I have most of the parts to do a similar job, chiller, TC-10 etc and the bits required to make a lid for the FV. You mentioned polypropylene and chopping boards iirc, I actually got a 250mm x 250mm x 5mm sheet of Acetal from these people good prices I think.

BTW do you know where can I get small cable glands (3mm) for the probe entry into the FV? I'm using a ATC-800 probe that is round as opposed to twin wire for more effective sealing, apparently it reads 1c less but as the TC-10 can be calibrated isn't a problem.

-

boingy

Re: chiller - what do I do now?

PG7 cable glands go down to 3mm (and some down to 2mm)

Rapid Electronics have a selection but their postage is a killer for small orders. www.rapidonline.com

There are a few nylon ones on ebay. Search for PG7 gland.

Rapid Electronics have a selection but their postage is a killer for small orders. www.rapidonline.com

There are a few nylon ones on ebay. Search for PG7 gland.

Re: chiller - what do I do now?

Farnell have 3mm cable glands but their minimum credit card order is £20

Maplin's have one down to 3.5mm - you could put some heatshrink sleeving over the cable maybe?

Scooby - good link for acetal sheet! Smaller chunks, and cheaper, than AltecWeb.

I have some heatshrink - I can put a couple of inches in an envelope if you're not going to need the rest of the metre length.

Maplin's have one down to 3.5mm - you could put some heatshrink sleeving over the cable maybe?

Scooby - good link for acetal sheet! Smaller chunks, and cheaper, than AltecWeb.

I have some heatshrink - I can put a couple of inches in an envelope if you're not going to need the rest of the metre length.

-

Scooby

Re: chiller - what do I do now?

edit1now wrote:Farnell have 3mm cable glands but their minimum credit card order is £20

Maplin's have one down to 3.5mm - you could put some heatshrink sleeving over the cable maybe?

Scooby - good link for acetal sheet! Smaller chunks, and cheaper, than AltecWeb.

I have some heatshrink - I can put a couple of inches in an envelope if you're not going to need the rest of the metre length.

I found the Maplin one in the end. Thanks for the offer e1n it's very kind of you, Chris has offered to send me some of his sleeving.

I also got a solid Acetal rod which I'm going to cut into disks to make some cam action clamps for the lid, when I get round to raking off the beer so I can measure up

Once again thanks for the offer.

Re: chiller - what do I do now?

I'd like to see a picture of your cam action clamps when you have time please?

-

Scooby

Re: chiller - what do I do now?

Will do, no pressure to do a good job thenedit1now wrote:I'd like to see a picture of your cam action clamps when you have time please?

I've disconnected the power to the chiller pump so it has it's own 13amp plug and boxed up the TC-10 with a cooling and heating sockets. I'm starting the lid soon as the beer is now in the keg and I can measure up.

Re: chiller - what do I do now?

No, take it easy, this is Bodge City!

I didn't measure anything properly when I did my box, just used jenny calipers. Engineers like Bru4u would have hedgehogs if they saw (rather than kittens).

I didn't measure anything properly when I did my box, just used jenny calipers. Engineers like Bru4u would have hedgehogs if they saw (rather than kittens).

-

Scooby

Re: chiller - what do I do now?

edit1now wrote:No, take it easy, this is Bodge City!

I didn't measure anything properly when I did my box, just used jenny calipers. Engineers like Bru4u would have hedgehogs if they saw (rather than kittens).

Jenny calipers

Re: chiller - what do I do now?

I've started playing with the 99p Maxi 310 in case I break it, before I move on to the definitely-working Maxi 110. I've changed the thermostat, probably unsuccessfully since it won't shut off, and brought the pump cable out to a separate IEC male socket.

Marked-out and pilot holes for jigsaw:

Hole after cleaning-up:

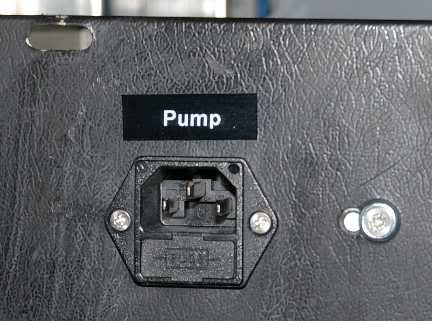

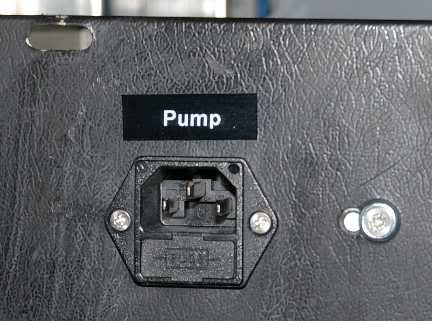

Fitted:

Rear view next to the replacement thermostat:

The connections couldn't be easier: find the pump wires, remove the Lucar spades from the terminal block and plug them onto the back of the IEC socket. There were some unused live terminals, which I covered by plugging sheathed Lucar females (blue in the picture) onto them to reduced the amount of live metalwork if I need to run it all with the top off

I've bodged-up a cooling loop out of 8mm copper:

Here's an old Boots heating belt:

and here's the test setup:

The hoses are cheap PVC 3/8" OD which push into the JG fittings on the python loop, and (after a dip in boiling water) push over the ends of the 8mm copper tube. I've lagged the hoses and the ends of the copper loop with bubble-wrap for the time being. The fermenter (22l of water) has borrowed one of the old boiler jackets.

It took about four hours for the water in the fermenter to go from 14C to 9C, during which time the ambient temperature rose from 14C to 21C, but I lagged the pipes at some point. 9C would be good for fermenting lager...

Since the Maxi 310 doesn't want to shut off with the cheap thermostat, I might replace it with a proper one from Harmony Hut, but also I'll install a socket for the Maxi 110's pump and try that with this setup.

A question for the likes of Sparky Paul: at the moment the pump on the Maxi 310 is earthed via the socket, which goes back to my TC-10 box and hence to the mains. Given that the pump is isolated (it's fixed on a plastic tank and has no parts connected to the metal box or any other wiring) is it OK like this or do I need to connect the earth from my new socket to the Maxi 310 box's earth terminals as well? I was concerned about creating an earth loop and maybe getting some corrosion.

Marked-out and pilot holes for jigsaw:

Hole after cleaning-up:

Fitted:

Rear view next to the replacement thermostat:

The connections couldn't be easier: find the pump wires, remove the Lucar spades from the terminal block and plug them onto the back of the IEC socket. There were some unused live terminals, which I covered by plugging sheathed Lucar females (blue in the picture) onto them to reduced the amount of live metalwork if I need to run it all with the top off

I've bodged-up a cooling loop out of 8mm copper:

Here's an old Boots heating belt:

and here's the test setup:

The hoses are cheap PVC 3/8" OD which push into the JG fittings on the python loop, and (after a dip in boiling water) push over the ends of the 8mm copper tube. I've lagged the hoses and the ends of the copper loop with bubble-wrap for the time being. The fermenter (22l of water) has borrowed one of the old boiler jackets.

It took about four hours for the water in the fermenter to go from 14C to 9C, during which time the ambient temperature rose from 14C to 21C, but I lagged the pipes at some point. 9C would be good for fermenting lager...

Since the Maxi 310 doesn't want to shut off with the cheap thermostat, I might replace it with a proper one from Harmony Hut, but also I'll install a socket for the Maxi 110's pump and try that with this setup.

A question for the likes of Sparky Paul: at the moment the pump on the Maxi 310 is earthed via the socket, which goes back to my TC-10 box and hence to the mains. Given that the pump is isolated (it's fixed on a plastic tank and has no parts connected to the metal box or any other wiring) is it OK like this or do I need to connect the earth from my new socket to the Maxi 310 box's earth terminals as well? I was concerned about creating an earth loop and maybe getting some corrosion.

-

Scooby

Re: chiller - what do I do now?

Got the colour balance sorted then e1n

I've just done a similar thing to a maxi 310 (free) and am always concerned about electrics and earthing etc so will be interested in the answer.

and am always concerned about electrics and earthing etc so will be interested in the answer.

I have just ordered 10mm ID x 9mm wall x 15m arrmaflex, more than I need so if you want some it would be 70p /m + postage.

Part way through my FV lid mod/temp control so will be posting some pics and info soon

I've just done a similar thing to a maxi 310 (free)

I have just ordered 10mm ID x 9mm wall x 15m arrmaflex, more than I need so if you want some it would be 70p /m + postage.

Part way through my FV lid mod/temp control so will be posting some pics and info soon