GARYSMIFF 'S SYSTEM (RIMS)

-

WishboneBrewery

- CBA Prizewinner 2010

- Posts: 7874

- Joined: Sun Nov 30, 2008 9:06 pm

- Location: Keighley, West Yorkshire

- Contact:

-

buckfast

Re: GARYSMIFF 'S SYSTEM (RIMS)

Neat system you got there. I'm still on the look out for a suitable heater for my system too. As you say, it's got to be easier to make two small holes seal that one big bugger. Do you have the part code for the heater? You say it's from the heating element company?

Again, nice work.....maybe one day

Cheers

Again, nice work.....maybe one day

Cheers

-

GARYSMIFF

Re: GARYSMIFF 'S SYSTEM (RIMS)

The pig tail heater you see was not from the Heating Element Company. it was out of an INTEX swimming pool heater.buckfast wrote:Neat system you got there. I'm still on the look out for a suitable heater for my system too. As you say, it's got to be easier to make two small holes seal that one big bugger. Do you have the part code for the heater? You say it's from the heating element company?

Again, nice work.....maybe one day

Cheers

The Childrens swimming pool heater was, I thought an all weather unit but turns out it let water in, when I contacted the company they only wanted me to send them the Plug (rcd) as proof of purchase they then sent me another heater unit, I decided to save the heater element as I thought ONE day i'll use that for something.

Now I will have a look around to see if I can find where I can get one as the unit has not leaked as its only a small hole required and the Silicone washer happy with the temps.

Watch this space I'll report back as soon as I find one, ill see if I can get one from people I bought from as expect its not a " user serviceable part"

-

buckfast

Re: GARYSMIFF 'S SYSTEM (RIMS)

Thanks for that.

I called the heating element company and they gave me part code 10940B. It's slightly different to the one you're using but is rated the same, and costs £19.78. I think I'll be looking to buy two for my boiler come pay day

Cheers

I called the heating element company and they gave me part code 10940B. It's slightly different to the one you're using but is rated the same, and costs £19.78. I think I'll be looking to buy two for my boiler come pay day

Cheers

-

GARYSMIFF

Re: GARYSMIFF 'S SYSTEM (RIMS)

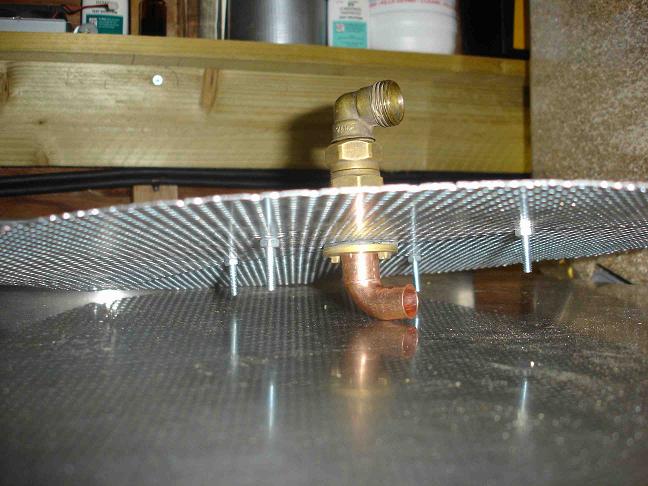

My new false bottom, but the 3mm holes are just too big, but the system works well with it ( no stuck mash's yet).

as soon as I can get some cheap 2mm 316 SSteel I will use this as my hop screen in the copper.

as soon as I can get some cheap 2mm 316 SSteel I will use this as my hop screen in the copper.

Last edited by GARYSMIFF on Wed Mar 16, 2011 2:19 am, edited 1 time in total.

-

EccentricDyslexic

Re: GARYSMIFF 'S SYSTEM (RIMS)

Hi chap,

i see your stick heater is very powerfull, if it can heat up water from 40 to 66 in such a short time, as i am about to order one, do you think i could get away with a 1 KW job?

Cheers!

Steve

i see your stick heater is very powerfull, if it can heat up water from 40 to 66 in such a short time, as i am about to order one, do you think i could get away with a 1 KW job?

Cheers!

Steve

-

rick_huggins

Re: GARYSMIFF 'S SYSTEM (RIMS)

This is my findings and plan also mate; I've seen some on Flea bay for £30 http://cgi.ebay.co.uk/ws/eBayISAPI.dll? ... K:MEWAX:IT but it's 306GARYSMIFF wrote:but the 3mm holes are just too big, but the system works well with it ( no stuck mash's yet).

as soon as I can get some cheap 2mm 316 SSteel I will use this as my hop screen in the copper.

-

grmills

Re: GARYSMIFF 'S SYSTEM (RIMS)

I doubt it, unless you're going for small volumes. I had a 1.5kW element in the bottom of my old boiler and it could barely maintain the temperature at 70-odd degrees, let alone raise it. That was working on about 25litres.EccentricDyslexic wrote: i see your stick heater is very powerfull, if it can heat up water from 40 to 66 in such a short time, as i am about to order one, do you think i could get away with a 1 KW job?

-

EccentricDyslexic

Re: GARYSMIFF 'S SYSTEM (RIMS)

Was your mash tun insulated? mine will be probably one of these- http://cgi.ebay.co.uk/ws/eBayISAPI.dll? ... 3D1&_rdc=1grmills wrote:I doubt it, unless you're going for small volumes. I had a 1.5kW element in the bottom of my old boiler and it could barely maintain the temperature at 70-odd degrees, let alone raise it. That was working on about 25litres.EccentricDyslexic wrote: i see your stick heater is very powerfull, if it can heat up water from 40 to 66 in such a short time, as i am about to order one, do you think i could get away with a 1 KW job?

I am about to order one.

Steve

-

GARYSMIFF

Re: GARYSMIFF 'S SYSTEM (RIMS)

rick_huggins

I was thinking of overlaying it with my Ikea Mesh screen or simply getting some copper wire wrapping it along the holes, that will then reduce the gap.

EccentricDyslexic

you could say 50mm of armaflex or armacell makes it insulated.

As I am sure you will be running your stick through a PID, I would get a big as you can afford, you can then limit power % to the stick, also make sure the stick is not limited with an internal cut out, like some of the radiator heaters.

I was thinking of overlaying it with my Ikea Mesh screen or simply getting some copper wire wrapping it along the holes, that will then reduce the gap.

EccentricDyslexic

you could say 50mm of armaflex or armacell makes it insulated.

As I am sure you will be running your stick through a PID, I would get a big as you can afford, you can then limit power % to the stick, also make sure the stick is not limited with an internal cut out, like some of the radiator heaters.

-

farmershort

Re: GARYSMIFF 'S SYSTEM (RIMS)

Hi All,

First time poster, brewer, and fresh new member - be gentle...

my main question for you all is, where do you get your kegs from for the setup as shown in gary's very impressive example... are they ally or SS?

also, are you using the ikea mesh thing in the bottom of the mash tun, or boiler, or both? If used in the boiler, do you loose the natural filtering ability of the hop leaves, as the surface area of the mesh is too big to allow a nice bed of hops to cover all of it?

Thanks all!

First time poster, brewer, and fresh new member - be gentle...

my main question for you all is, where do you get your kegs from for the setup as shown in gary's very impressive example... are they ally or SS?

also, are you using the ikea mesh thing in the bottom of the mash tun, or boiler, or both? If used in the boiler, do you loose the natural filtering ability of the hop leaves, as the surface area of the mesh is too big to allow a nice bed of hops to cover all of it?

Thanks all!

-

GARYSMIFF

Re: GARYSMIFF 'S SYSTEM (RIMS)

Greetings,

Kegs are SS.

The Ikea Mesh I was using as a bottom for the mash tun but have changed this to a SSteel screen see pics (on the lookout for 2mm holes rather than 3mm, but 3mm would be fab for copper/hop filter).

Not used mesh in a Boiler ( I use a SSteel tray with a few holes see pics but in transition to another method(Perf SSteel 3mm)) but would say the natural filtering ability of the hop leaves would only be helped by the openness of the mesh and its a cheap option to get you going provided you have a round bottom on your MT or Copper.

you can always look at the Plate method and hop strainer pipe or that Interweb thingy

Ideas here, not all links work but will keep you bizzy http://www.brewzilla.nl/?brewhalla

PS Welcome and thx for letting me be your 1st post.

post.

Kegs are SS.

The Ikea Mesh I was using as a bottom for the mash tun but have changed this to a SSteel screen see pics (on the lookout for 2mm holes rather than 3mm, but 3mm would be fab for copper/hop filter).

Not used mesh in a Boiler ( I use a SSteel tray with a few holes see pics but in transition to another method(Perf SSteel 3mm)) but would say the natural filtering ability of the hop leaves would only be helped by the openness of the mesh and its a cheap option to get you going provided you have a round bottom on your MT or Copper.

you can always look at the Plate method and hop strainer pipe or that Interweb thingy

Ideas here, not all links work but will keep you bizzy http://www.brewzilla.nl/?brewhalla

PS Welcome and thx for letting me be your 1st

Last edited by GARYSMIFF on Mon Oct 19, 2009 11:56 pm, edited 1 time in total.

-

rick_huggins

Re: GARYSMIFF 'S SYSTEM (RIMS)

I've tried the stainless mesh too but grain gets stuck in it and it's a RPITA to get out... Best to swap out for 2mm plating; we'll thats my plan at least

-

GARYSMIFF

Re: GARYSMIFF 'S SYSTEM (RIMS)

Good call, I'll get some 2mm and use the 3mm for the Hop Strainer in the copper, unless I find a nice big cheap bit.

This looks nice.

or http://images.google.co.uk/imgres?imgur ... g%26sa%3DG

This looks nice.

or http://images.google.co.uk/imgres?imgur ... g%26sa%3DG

-

EccentricDyslexic

Re: GARYSMIFF 'S SYSTEM (RIMS)

Gary Smiff, i know yours in insulated i was refering to grmills. Do all PIDs have power limiting capabilities?GARYSMIFF wrote:rick_huggins

I was thinking of overlaying it with my Ikea Mesh screen or simply getting some copper wire wrapping it along the holes, that will then reduce the gap.

EccentricDyslexic

you could say 50mm of armaflex or armacell makes it insulated.

As I am sure you will be running your stick through a PID, I would get a big as you can afford, you can then limit power % to the stick, also make sure the stick is not limited with an internal cut out, like some of the radiator heaters.

steve