Another convoluted post. Does this brewing lark get any easier..?

Tasty!

I started supping it (for research purposes) after a couple of weeks in the keg. It tasted great! Really happy with the result

I worked away from home for a couple of weeks, which gave what was left time to mature - the last few pints were truly tasty

But now, gather round for the sorry tale of AG #002

I made a yeast starter with some DME for a vial of WLP002 a few days before brewday.

Boiling the wort

With one AG under my belt, I felt pretty confident about this brew - in fact, I was so excited about it I was up before 5am to get started

Grains

As with the previous brew, the only water treatment I performed was a boil-up the night before & a campden tablet.

Using notes from the first brew (invaluable!) everything went pretty smoothly. Although, I did put all of the mash & top-up liqour in the tun... thankfully, I realised before I added the grain!

The mash temp was out by a degree (67c) nothing major though...

Small mash in a big tun!

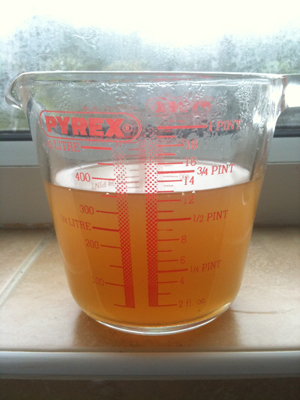

First runnings

As with AG #001, I managed to squeeze out 13L from each batch...

As the second batch worked its way out, I weighed the hops...

Hops

With 26 litres of wort in the boiler, I fired it up and bought the temperature up. As it reached about 85ish, it conked out!

The indicator light turned red and the power light went out...

Red light of death

I rolled the dial back to zero and tried again. That bought it back to life for a few minutes, then dead again.

I got onto the 'kit for advice, wondering how long the pre-boiled wort would keep. It had to go...

The wort went down the toilet

So, that was the end of AG #002.

With a bit more time on my hands, I scoured the 'kit for overheating advice and found that even small amounts of scale and burnt wort can be a problem, I bought some descaler and cleaned up the element.

Before

After

I gave it a good testing with around 20 litres of water, letting it boil for an hour. It gave me the red light once as it approached boiling-point, then happily gave me a rolling boil without any problem

AG #002b:

Once again, made a starter a few days before brewday and toasted it for luck with ESB

Toasting the new starter

On brewday, I made sure there was NOTHING else planned for the day, so I could give the brew full attention. And this means a proper breakfast

A proper start to the day

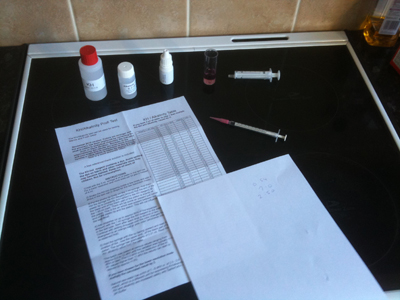

Getting a bit more confident, I thought I'd try some simple water treatment and used the Salifert kit to test the alkalinity.

Alkalinity test

I used Graham's calculator and put in the necessary additions...

Grain and treatment

Mashing went well - hit 67 degrees C at the start and just under that at the end

Sparge!

Again, collected 26 litres for the boiler

Coming to the boil

With wort in the boiler heating up, I took out the hops I'd weighed and stored for AG #002 ready to drop in.

Hops - again...

You ALL know what's coming next, don't you?

!!!!

Off the boil

The boiler conked out again as it started boiling. This time though, I left it to see what would happen.

After a few moments, it came back to life:

On the boil

Rolling boil once again!

Realising that I'd be getting an on-off boil, I thought I'd take some wort from the boiler and give it a blast in 2 - 3 litre amounts on the hob, then chuck it back in.

Desperate measures

When the wort had boiled down to it's final volume (which took a while longer than anticipated) I chilled it down...

Chill out

Decent looking break

Break

Transferred it to the FV

Transfer

Decent looking wort

Clear

Checked the gravity (1042 at 27 deg C) and, when ready, pitched the starter and put the FV in the fermenting fridge.

FV in the fridge with an 'innocent halo'

Next morning - looking good

Mr. Whippy

Next on the agenda - fault finding. Advice welcomed!

Cheers,

FB.