Kev888,

I’ve been reading about rocket stoves used in developing countries to cook food using just a few handfuls of sticks and twigs. Been wondering if some of the principles could be used in homebrewing.

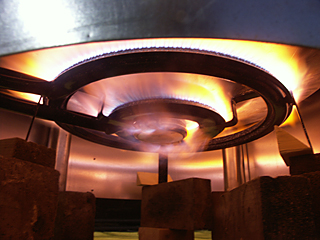

An important feature of institutional rocket stoves (ie. those used to prepare big pots of food for a whole village) is the use of a skirt (or shroud) on the outside of the pot to contain the hot combustion gases and channel them up the sides. This puts the pot sides to use as a heating surface thus greatly increasing the heating efficiency of the stove and reducing fuel consumption.

You are using gas instead of wood as a fuel, but the thermodynamic principle of the skirt is the same.

Aid agencies have done a lot of engineering work into the mathematical relationship between the diameter of the pot and the diameter of the skirt. This information can be found at this website:

http://www.rocketstove.org/index.php/de ... -from-menu

This page has links to two PDF files and an spreadsheet. The spreadsheet has at the top a few basic parameters (in grey) such as pot circumference, pot height etc. Just key in the measurements of your pot and it will calculate the size of the piece of sheet steel needed to produce a skirt with the best gap for thermodynamic efficiency. (Edit: The web page says that you need Firefox web browser to access the spreadsheet. But it works fine for me using Internet Explorer 11 and XL).

The two PDFs are good to browse to get an idea of how rocket stoves work, or just look up the many YouTube videos (note that many rocket stoves don’t use a skirt – it is the big “institutional” rocket stoves you need to look for).

Couple of points I’ve considered when thinking about using a skirt to help boil wort.

(1) In order to extend the ball valve out the extra distance to get clear of the surrounding skirt, you are going to need a longer nipple or pipe extension.

(2) If using a weldless fitting for the drain tap, don’t have a silicone washer or O-ring on the outside of the pot – it would be burnt by the high heat rising up the side of the pot (catastrophic failure if full of hot wort). Same for the gasket inside your ball valve – if the valve gets too hot it could fail.

(3) Even with a O-ring on the inside there could be too much heat being conducted through the pot wall to the O-ring causing it to degrade and fail. I’d look at cutting vertical slot a few inches wide in the skirt to accommodate the valve. I’d bend the skirt metal in beneath the tap to shield it from the hot gases. And similarly, I’d bend in the vertical edges of the slot to keep the hot gases channelled against the pot.

(4) Consider having the height of the skirt much less than the height of the pot. Reason being that if you heat the pot wall area that is not in contact with wort you could cause severe scorching or burning of wort that splashes about during the boil. The heat might also burn out the pot metal from the sides (especially if aluminium). So I’d keep the skirt height well below the level of the wort; and never have the gas turned on and firing until you’ve filled the pot to above the level of the top of the skirt.

I agree with your thinking about leaving the top of the skirt/shroud open to allow hot combustion gases to vent. Closing off the top of the skirt could cause the gases to billow out underneath the pot and cause problems with oxygen starvation to the gas burner, or worse - burning the gas feed line.

Anyway, good luck with this project. I’m interested in seeing how you go. I’m guessing (hoping) you can reduce gas consumption by 50% using a skirt.