I got there a bit late but helped with the doughing in (notice the sparge arm that Chris fixed to the mash tun)

This is the fermentation room on the second level, the HLT is in the top left hand corner, the rest are fermenters. That brown bin is the fermentation lock.

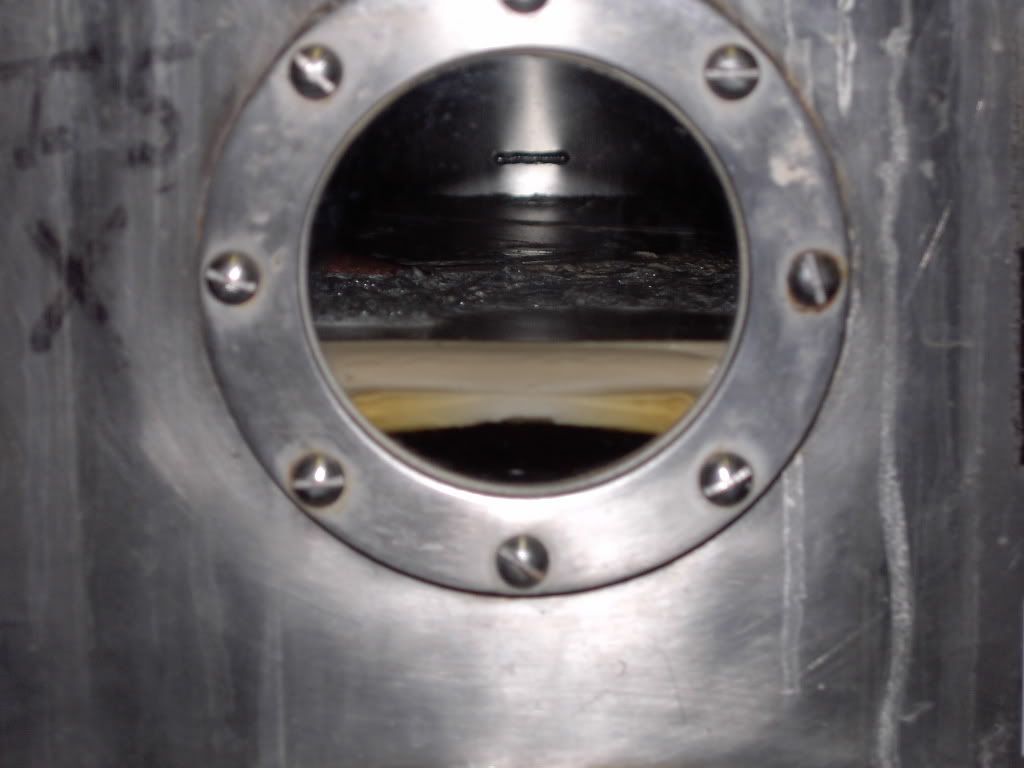

I helped clear out the old yeast from the FV before Chris got inside and started scrubbing the beerstone from it) There's also a copper coil at the top which is out of shot which helps regulate the temp of the wort during fermentation.

Downstairs again and the start of the sparging.

Heres the copper, Chris said this was rescued from a field somewhere, I think he said it was used to pasturise milk.

Recirculating the first runnings.

This pump has an automatic value on it when the bucket gets full and the pipe then transfers the wort to the copper.

The copper going like hell after the bittering hops have been added (it really clears your head when you go in there!)

Here's Chris cooling down the wort using a cylinder inside another one (sorry don't know the technical name for it) before taking a reading.

Using this hydrometer (I now feel totally vindicated using my cheap hydrometer

Ph reading being taken from wort from the various brewing stages, Chris uses a Ph buffer of 4 and another of 6 or 7 (can't really remember now) before taking a reading.

This is the heat exchanger which is hooked upto a digital thermometer when the worts ready to be transferred to the FV.

Heres the FV filling up, (the wort's being pumped up from downstairs.)

Danstar Nottingham yeast is used (sorry about the quality of the photo).

Rehydrating the yeast.

Finally, Chis pitches in the yeast!

I hope I got all this in order but I may not have. Anyway, I had a great day.

Cheers.

Tom